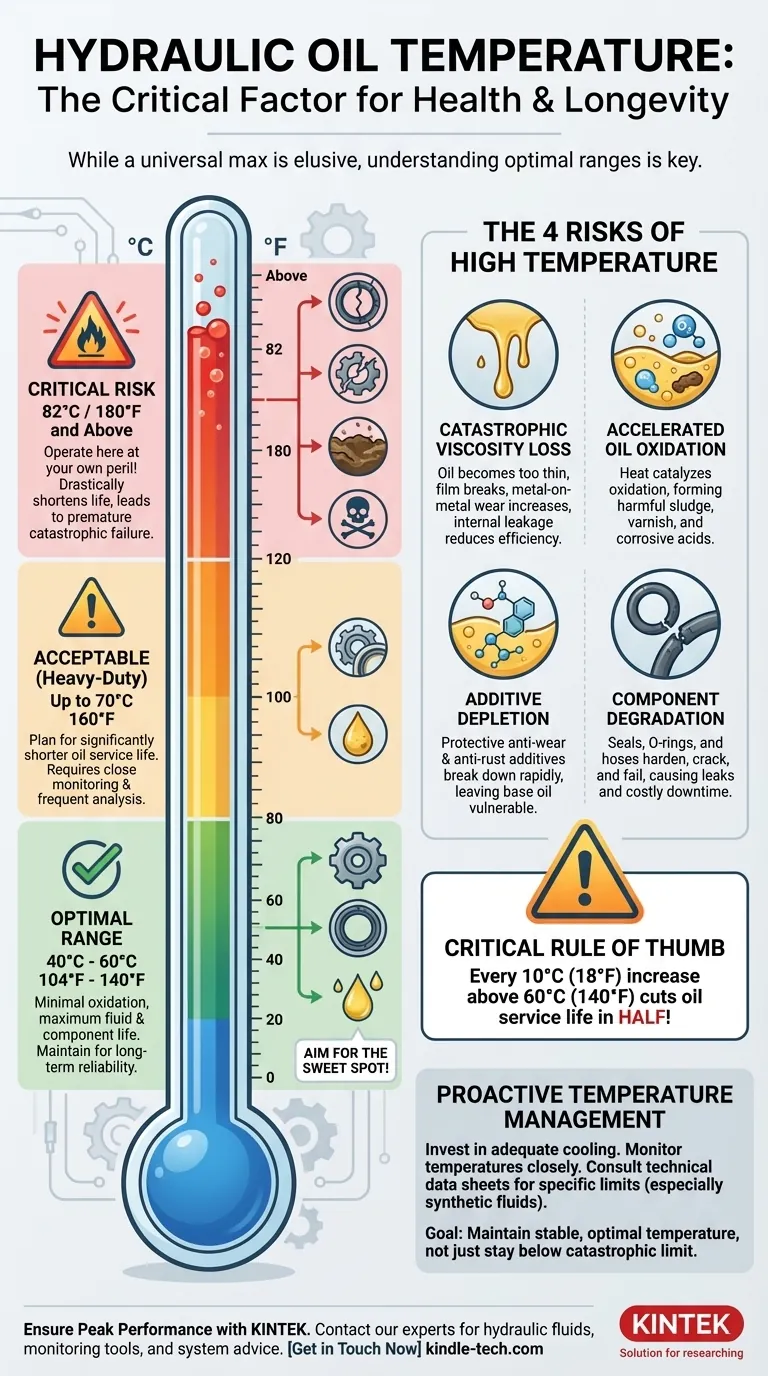

While a definitive universal maximum does not exist, the generally accepted maximum permissible temperature for standard mineral-based hydraulic oil in a stationary system is 82°C (180°F). Operating continuously above this temperature drastically shortens the life of the oil and system components, leading to premature failure. The ideal, however, is significantly lower.

The core issue isn't a single "maximum" temperature, but rather understanding that every degree above an optimal range accelerates fluid degradation and component wear. The goal should be to maintain a stable, optimal temperature, not simply to stay below a catastrophic limit.

Why Temperature is the Critical Factor in Hydraulic Health

Hydraulic systems are designed to operate within a specific fluid viscosity range. Temperature is the single most significant factor that alters this viscosity, directly impacting both performance and reliability.

The Problem with "Too Hot"

Excessive heat is the primary enemy of a hydraulic system. It thins the oil, breaks down its chemical properties, and attacks physical components like seals and hoses.

The Problem with "Too Cold"

Conversely, oil that is too cold is too thick. This can lead to sluggish operation, pump cavitation, and poor lubrication on start-up. Most systems incorporate a warm-up period to address this.

The Four Primary Risks of High Oil Temperature

Exceeding the optimal temperature range introduces four distinct and compounding risks to your system. Understanding these makes the case for proactive temperature management.

Catastrophic Viscosity Loss

As oil heats up, its viscosity (resistance to flow) drops. When the oil becomes too thin, it can no longer maintain an effective lubricating film between moving parts, leading to increased metal-on-metal wear. This also increases internal leakage past seals in pumps, motors, and cylinders, reducing system efficiency and generating even more heat.

Accelerated Oil Oxidation

Heat acts as a catalyst for oxidation, the chemical reaction between the oil's hydrocarbons and oxygen. This process degrades the oil, forming sludge, varnish, and corrosive acids.

A critical rule of thumb is that for every 10°C (18°F) increase above 60°C (140°F), the oil's service life is cut in half.

Additive Depletion

Modern hydraulic oils contain a sophisticated package of additives for anti-wear, anti-rust, and anti-foaming properties. High temperatures cause these additives to break down and deplete far more rapidly, leaving the base oil unprotected and ineffective.

Component Degradation

The soft parts of a hydraulic system are the most vulnerable to heat. Seals, O-rings, and hoses have specific temperature ratings. When exceeded, they will harden, become brittle, and crack, resulting in leaks and costly failures.

Understanding the Trade-offs: The Ideal vs. The Maximum

The distinction between an optimal operating range and a maximum permissible temperature is crucial for maintenance and system design.

The "Maximum" Permissible Temperature

Consider 82°C (180°F) a red line. Operating here, even for short periods, causes irreversible damage. If your system consistently reaches this temperature, it indicates a serious problem with system design or a component failure (e.g., a faulty relief valve or an undersized cooler).

The "Optimal" Operating Range

For maximum fluid life and system reliability, the ideal operating range is between 40°C and 60°C (104°F and 140°F). Within this "sweet spot," the oil maintains its specified viscosity, additives remain effective, and oxidation occurs at a negligible rate.

Factors That Influence Your Specific Limit

While these are general guidelines for mineral oils, specific limits can change. Systems using synthetic fluids may have higher temperature tolerances. Always consult the technical data sheets for both your hydraulic fluid and your system's components (especially seals and hoses) to determine their specific limits.

How to Apply This to Your System

Your operational goal should dictate your approach to temperature management.

- If your primary focus is maximum system lifespan and reliability: You must invest in adequate cooling to consistently maintain oil temperatures between 40°C and 60°C (104°F - 140°F).

- If your system runs heavy-duty, high-pressure cycles: You may need to accept operating temperatures up to 70°C (160°F), but you must also plan for a significantly shorter oil service life and more frequent fluid analysis.

- If you are diagnosing an overheating problem: Any sustained temperature reading above 82°C (180°F) is a critical alarm that requires immediate investigation to prevent catastrophic failure.

Proactive temperature control is the single most effective strategy for ensuring the long-term health and efficiency of your hydraulic system.

Summary Table:

| Temperature Range | Status & Impact | Key Risk |

|---|---|---|

| 40°C - 60°C (104°F - 140°F) | Optimal Range | Minimal oxidation, maximum fluid & component life. |

| Up to 70°C (160°F) | Acceptable (Heavy-Duty) | Plan for shorter oil life; monitor closely. |

| 82°C (180°F) and Above | Maximum / Critical Risk | Oil life halves every 10°C above 60°C; risk of catastrophic failure. |

Is your hydraulic system running too hot? Protect your investment and ensure peak performance.

KINTEK specializes in the precise equipment and consumables that keep your laboratory and industrial systems running reliably. Whether you need high-quality hydraulic fluids, monitoring tools, or expert advice on system maintenance, we are here to support your operational goals.

Contact our experts today to discuss how we can help you maintain optimal temperatures and extend the life of your critical equipment.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- How does axial pressure influence Al2O3-TiCN/Co-Ni ceramics? Optimize Densification and Microstructure

- How does a laboratory hydraulic press assist in the preparation of standardized porous ceramic substrates? Precision Prep

- How is a uniaxial hydraulic press utilized in the formation of solid-state electrolyte pellets? Boost Ionic Conductivity

- What is the function of a laboratory hydraulic press and a 15 mm circular mold? Create Dense Oxygen Membrane Green Bodies

- What role does a laboratory hydraulic press play in preparing LixScCl3+x samples for EIS? Achieve Reliable Conductivity

- How do you control pressure in a hydraulic system? Master Flow Resistance for Optimal Performance

- What happens when a hydraulic system overheats? Prevent Costly Damage and Downtime

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra