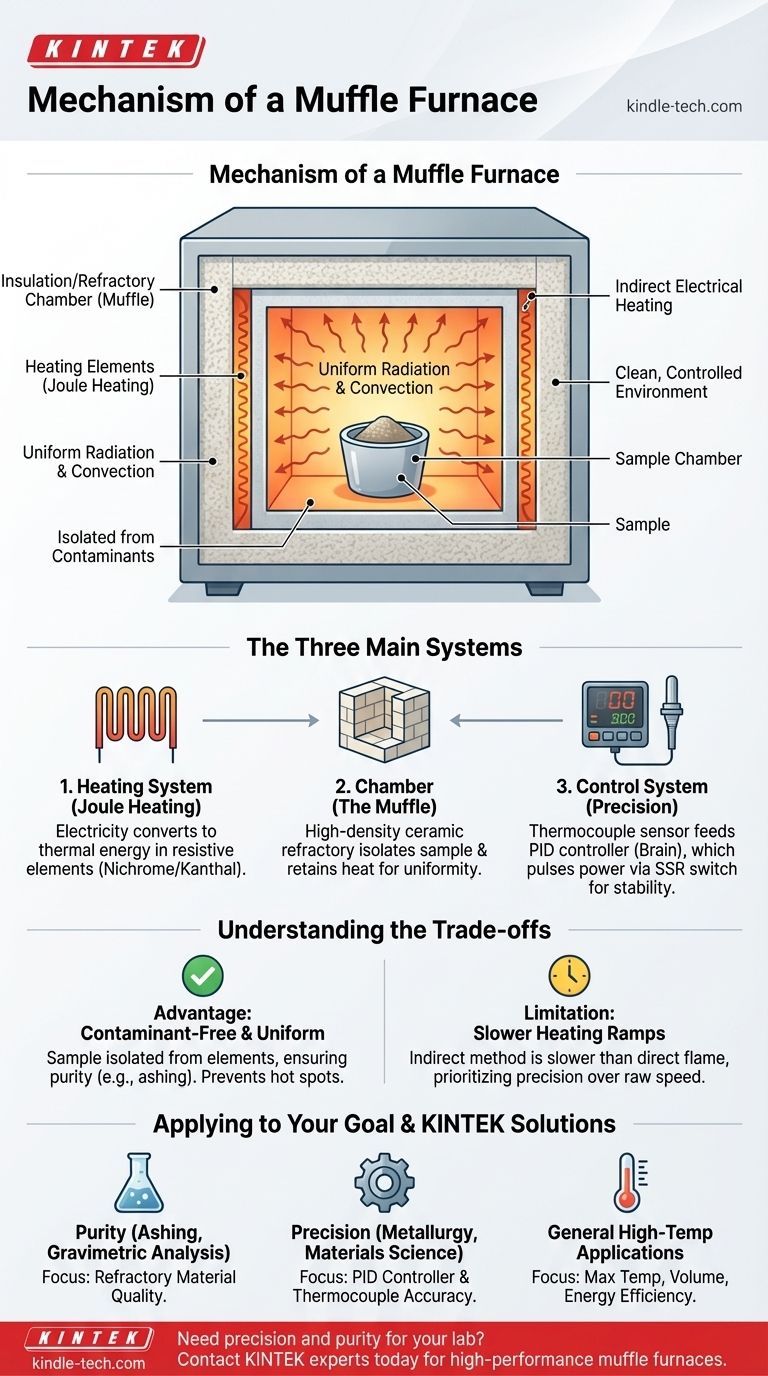

At its core, a muffle furnace operates on the principle of indirect electrical heating within a thermally insulated chamber. It uses resistive heating elements to heat the chamber's interior, which then radiates heat uniformly onto the sample. This mechanism ensures the material is heated in a clean, controlled environment, completely isolated from the heating elements and any potential contaminants.

The term "muffle" refers to the furnace's defining feature: a separated, insulated chamber that muffles the sample from the raw heat source. This ensures uniform heating and prevents contamination, which is the furnace's primary purpose.

How a Muffle Furnace Generates and Controls Heat

The entire process is a feedback loop involving three main systems: the heating system, the chamber (muffle), and the control system. Each plays a distinct role in achieving precise, high temperatures.

The Principle: Converting Electricity to Heat

A muffle furnace generates heat using the principle of Joule heating, also known as resistive heating.

An electric current is passed through high-resistance heating elements, typically made of materials like Nichrome or Kanthal. As the current encounters this resistance, electrical energy is converted directly into thermal energy, causing the elements to glow red-hot.

The Chamber: The Insulating "Muffle"

The heating elements are positioned around the outside of the main chamber, but not inside it. This chamber is the "muffle."

It is constructed from high-density, heat-resistant refractory materials, like ceramic bricks or fibers. This material serves two critical functions: it can withstand extreme temperatures and it prevents heat from escaping, ensuring energy efficiency.

The Transfer: Uniform Heating by Radiation

The hot elements heat the walls of the muffle chamber. These superheated walls then transfer thermal energy to the sample placed inside primarily through radiation and convection.

This indirect method is crucial because it ensures the entire sample is heated evenly from all sides, avoiding hot spots that could occur with direct heating.

The Control System: Achieving Precision

A muffle furnace's utility comes from its ability to maintain a precise temperature. This is managed by a sophisticated electronic control system.

The Sensor: The Thermocouple

A thermocouple, a highly sensitive temperature sensor, is placed inside the chamber to constantly monitor the internal temperature. It sends this data back to the main controller in real-time.

The Brain: The PID Controller

The "brain" of the furnace is the PID (Proportional-Integral-Derivative) controller. This microprocessor continuously compares the actual temperature from the thermocouple to the desired temperature set by the user (the setpoint).

Based on the difference, the PID controller calculates exactly how much power needs to be sent to the heating elements.

The Switch: The Solid-State Relay (SSR)

The PID controller doesn't power the elements directly. Instead, it sends signals to a high-power switch, often a Solid-State Relay (SSR) or contractor.

This relay rapidly pulses power to the heating elements, turning them on and off many times per second to maintain the target temperature with incredible stability.

Understanding the Trade-offs

The design of a muffle furnace is a direct result of specific engineering trade-offs focused on purity and precision over raw speed.

The Advantage: A Contaminant-Free Environment

The key benefit of the muffle design is isolation. In historical fuel-fired furnaces, the muffle was a physical barrier that protected the sample from soot and combustion byproducts. In modern electric furnaces, it isolates the sample from any potential flaking or outgassing from the heating elements themselves.

The Limitation: Slower Heating Ramps

Because the heating is indirect (elements heat the chamber, which heats the sample), the initial time to reach a high temperature can be slower than methods like induction or direct flame heating. However, this trade-off is accepted to gain superior temperature uniformity and a clean environment.

Applying This to Your Goal

Understanding the mechanism helps you identify the features that matter most for your specific application.

- If your primary focus is material purity (e.g., ashing, gravimetric analysis): The quality and integrity of the muffle chamber's refractory material is the most critical factor.

- If your primary focus is precise heat treatment (e.g., metallurgy, materials science): The sophistication of the PID controller and the accuracy of the thermocouple are paramount.

- If your primary focus is general high-temperature applications: The maximum operating temperature, chamber volume, and energy efficiency will be your key decision points.

Ultimately, the muffle furnace is an indispensable tool precisely because its mechanism prioritizes a controlled, clean, and uniform heating environment.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Heating Elements | Generate heat via electrical resistance (Joule heating) | Made of Nichrome/Kanthal; heat the chamber walls |

| Muffle Chamber | Insulated chamber that holds the sample | Made of refractory ceramic; ensures uniform heating and isolation |

| Heat Transfer | Transfers heat to the sample | Primarily via radiation for even temperature distribution |

| Control System (PID) | Maintains precise temperature | Uses thermocouple feedback to adjust power via a solid-state relay |

Need a muffle furnace that guarantees precision and purity for your lab?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for critical applications like ashing, heat treatment, and materials testing. Our furnaces deliver the contaminant-free environment and precise temperature control your research demands.

Contact our experts today to find the perfect muffle furnace for your specific laboratory needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What function does a high-temperature muffle furnace perform during the synthesis of La0.6Sr0.4CoO3-δ perovskite oxides?

- What is the difference between a muffle furnace and a chamber furnace? Understand the Key Distinctions for Your Lab

- Which furnace is used for heat treatment of small parts? Select the Right Tool for Your Process

- What is the process of a muffle furnace? From Electricity to Precision High-Temp Control

- Does tempering steel increase hardness? Discover the Essential Trade-off for Toughness

- What is the role of a laboratory oven in processing nitric acid-modified mesoporous carbon? Optimize Catalyst Supports

- What temperature does porcelain fire at? A Guide to the 1222°C-1300°C Range for Perfect Results

- What is the muffle furnace used to estimate? Measure Ash Content and Volatile Matter Precisely