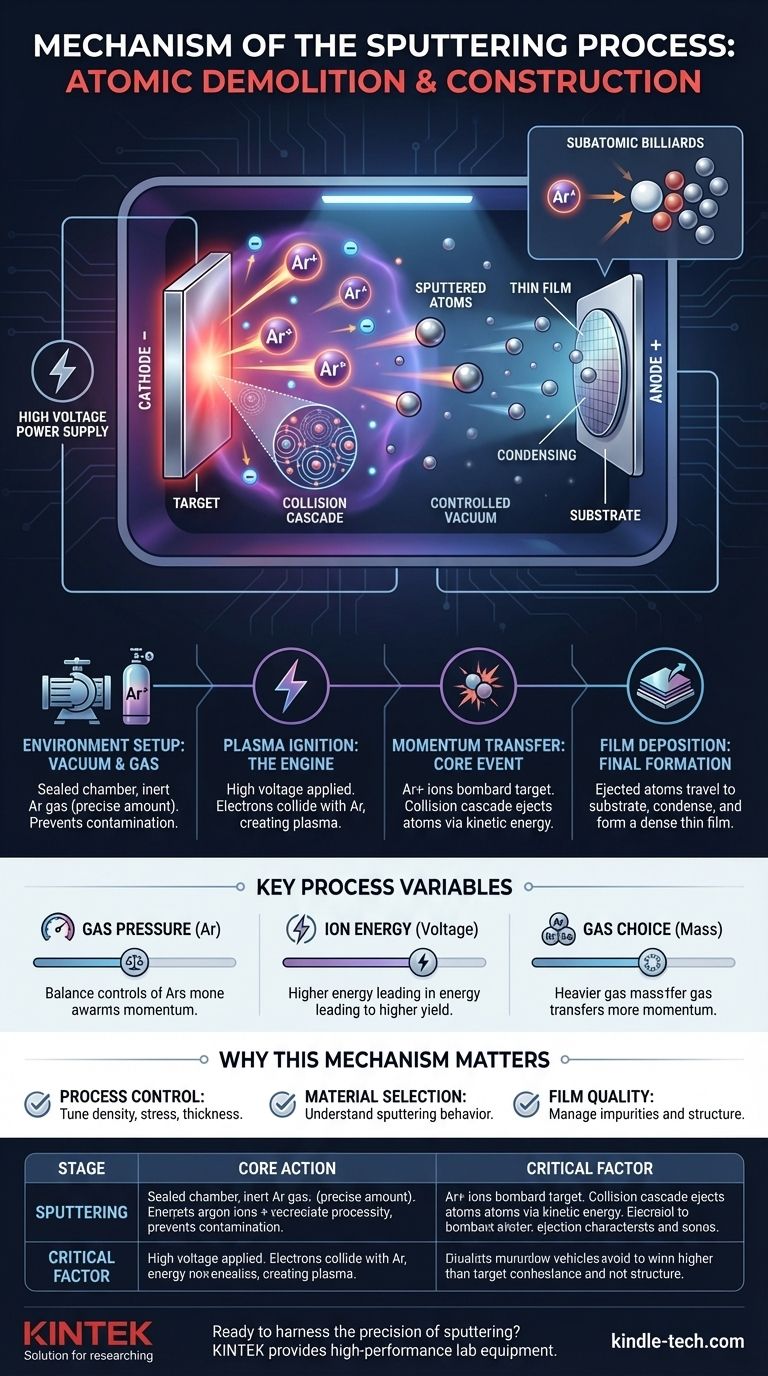

At its core, sputtering is a physical process of demolition and construction at the atomic scale. It uses high-energy ions from a plasma to physically knock atoms off a source material (the "target") and deposit them as an ultra-thin film onto a different surface (the "substrate") within a vacuum.

The mechanism is not chemical or thermal; it is a purely mechanical momentum transfer. Think of it as a subatomic game of billiards: an energetic ion acts as the cue ball, striking atoms in the target material and ejecting them with enough force to travel and coat a nearby substrate.

The Sputtering Environment: A Controlled Vacuum

To understand the sputtering mechanism, we must first look at the highly controlled environment where it takes place.

The Need for a Vacuum

The entire process occurs inside a sealed vacuum chamber. Air and other contaminants are pumped out for two critical reasons: to prevent unwanted chemical reactions with the materials and to give the sputtered atoms a clear, collision-free path from the target to the substrate.

Introducing the Sputtering Gas

Once a vacuum is established, a small, precise amount of an inert gas—most commonly Argon (Ar)—is introduced. Argon is used because it is chemically non-reactive and has sufficient mass to eject target atoms effectively upon impact.

Igniting the Plasma: The Engine of the Process

The inert gas is useless until it is energized into a plasma, which provides the "ammunition" for the sputtering process.

Applying a High Voltage

The target material is connected to a negative voltage source (becoming a cathode), while the chamber or a separate electrode acts as the anode (positive). This creates a strong electric field within the chamber.

Creating the Plasma

This electric field accelerates stray free electrons, causing them to collide with the neutral Argon gas atoms. These high-energy collisions knock electrons off the Argon atoms, creating positively charged Argon ions (Ar+) and more free electrons. This self-sustaining cascade creates a glowing, energized gas known as a plasma.

The Core Event: Momentum Transfer and Ejection

With the plasma established, the central action of sputtering can begin. This is a purely physical event driven by kinetic energy.

Ion Bombardment

The newly formed, positively charged Argon ions (Ar+) are now powerfully attracted and accelerated towards the negatively charged target material. They strike the target surface with significant kinetic energy.

The Collision Cascade

A single incoming ion does not simply "chip off" a surface atom. Instead, its impact transfers momentum deep into the target's atomic structure, setting off a chain reaction of atom-on-atom collisions known as a collision cascade.

Atom Ejection

When this cascade of energy and momentum reaches the target's surface, it can give a surface atom enough energy to overcome its atomic binding forces. At this point, the atom is physically ejected, or "sputtered," from the target.

Deposition: Forming the Thin Film

The final stage is the journey of the ejected atoms and their subsequent formation into a new layer.

The Journey to the Substrate

The sputtered atoms travel through the vacuum chamber, typically in a straight line-of-sight path. They move from an area of high concentration (the target) to an area of low concentration.

Nucleation and Growth

These atoms land on the strategically placed substrate. There, they cool, condense, and bond to the surface, gradually building up layer by atomic layer to form a dense, uniform, and highly pure thin film.

Understanding Key Process Variables

The elegance of sputtering lies in its controllability. By tuning key parameters, you can precisely dictate the outcome of the film.

The Role of Gas Pressure

The pressure of the sputtering gas (e.g., Argon) is a delicate balance. If it's too high, sputtered atoms will collide with gas atoms and scatter before reaching the substrate. If it's too low, the plasma will be too weak, resulting in a very slow deposition rate.

The Impact of Ion Energy

The voltage applied to the target controls the energy of the bombarding ions. Higher energy increases the sputter yield (the number of atoms ejected per incoming ion), leading to faster deposition. However, excessively high energy can damage the substrate or the growing film.

The Choice of Sputtering Gas

While Argon is common, heavier inert gases like Krypton or Xenon can transfer momentum more efficiently due to their greater mass. This increases the sputter yield but also increases the operational cost.

Why This Mechanism Matters

Understanding the step-by-step mechanism of sputtering moves you from a passive observer to an active controller of the process.

- If your primary focus is process control: The link between voltage, pressure, and the collision cascade allows you to precisely tune film properties like density, stress, and thickness.

- If your primary focus is material selection: Knowing the mechanism explains why materials with lower atomic binding energy sputter more easily, which is a critical factor in designing a process.

- If your primary focus is film quality: Grasping how ion bombardment works helps you manage potential impurities or structural damage in the growing film, leading to higher-performance coatings.

By understanding sputtering as a physical momentum exchange, you gain direct control over the creation of materials at the atomic scale.

Summary Table:

| Key Stage | Core Action | Critical Factor |

|---|---|---|

| Environment Setup | Create a vacuum chamber with inert gas (Argon) | Prevents contamination & allows clear atom path |

| Plasma Ignition | Apply high voltage to create plasma (Ar+ ions) | Provides the energetic ions for bombardment |

| Momentum Transfer | Ions strike target, initiating a collision cascade | Physical ejection of target atoms via kinetic energy |

| Film Deposition | Ejected atoms travel and condense on the substrate | Forms a dense, uniform, and pure thin film |

Ready to harness the precision of sputtering in your lab? KINTEK specializes in high-performance lab equipment and consumables for thin-film deposition and materials science. Whether you are developing advanced semiconductors, optical coatings, or specialized surface treatments, our expertise and reliable equipment ensure your processes achieve superior film quality and consistency. Contact our experts today to discuss how we can support your laboratory's specific needs.

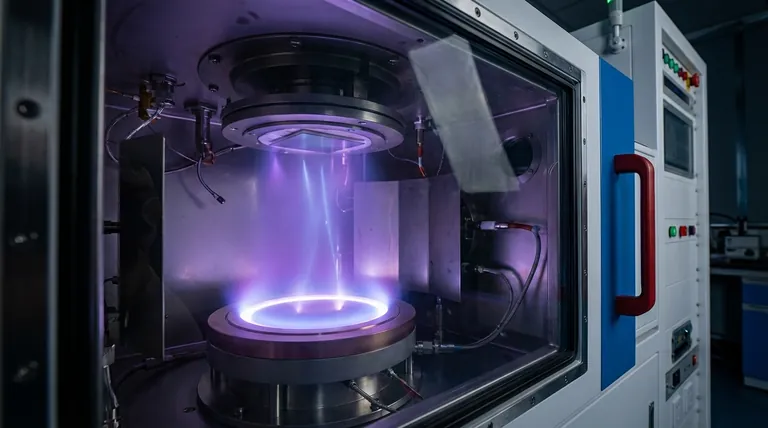

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the mechanical function of an overhead digital stirrer? Optimize Molybdenum Disk Dissolution Efficiency

- What are the waste products of biomass? Uncover Byproducts from Ash to Biochar

- Does graphite lead electricity? Unlocking the Secrets of Its Atomic Structure

- What is the difference between pyrolysis and decomposition? Unlock the Power of Controlled Thermal Processing

- What are the factors that can affect the rate of melting? Master the Science of Heat Transfer

- How thick is the sputter coating for SEM? Achieve Optimal Imaging & Analysis

- Why graphite Cannot conduct electricity? Unlocking the Secret of its High Electrical Conductivity

- How long does SEM trim paint take to cure? A Guide to Drying vs. Full Durability