In essence, the melting furnace process is a controlled industrial method for converting solid metals into a liquid state by applying intense heat. The most common and efficient modern method, used in foundries and casting operations, is the induction melting furnace, which uses the principles of electromagnetic induction to generate heat directly within the metal itself, ensuring a clean and uniform melt.

The core principle to understand is that modern melting furnaces do not simply "bake" metal with external flames. Instead, they use advanced methods like electromagnetic fields to generate heat from within the material, offering superior control over temperature, purity, and alloy consistency.

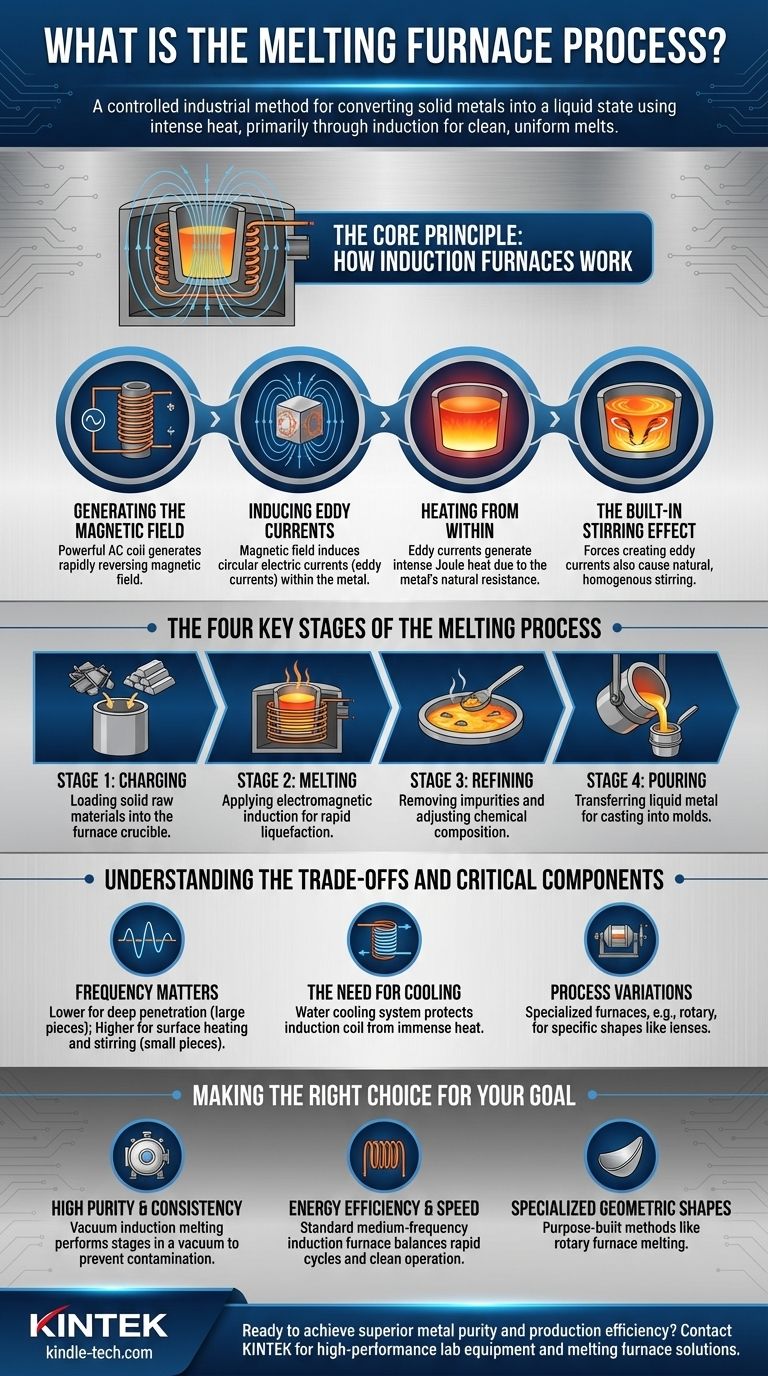

The Core Principle: How Induction Furnaces Work

The induction melting process is a clean, energy-efficient, and highly controllable method. Its operation relies on fundamental principles of physics to achieve rapid and uniform melting without direct contact from a heating element.

Generating the Magnetic Field

An induction furnace uses a powerful coil, typically made of copper tubing, which is connected to an alternating current (AC) power supply. When electricity flows through this coil, it generates a strong and rapidly reversing magnetic field in the space at the center of the coil, where a crucible containing the metal charge is placed.

Inducing Eddy Currents

This powerful alternating magnetic field penetrates the metal placed inside the crucible. As the magnetic field lines cut through the conductive metal, they induce small, circular electric currents within the metal itself. These are known as eddy currents.

Heating From Within

The induced eddy currents flow through the metal, which has natural electrical resistance. This resistance to the flow of current generates intense heat, a phenomenon known as Joule heating. Crucially, the heat is generated inside the metal, not applied from an external source, leading to very rapid and efficient melting.

The Built-in Stirring Effect

A unique advantage of the induction process is that the same forces that create the eddy currents also cause the molten metal to stir vigorously. This natural stirring action ensures the melt is homogenous, distributes alloying elements evenly, and maintains a uniform temperature throughout the batch.

The Four Key Stages of the Melting Process

Regardless of the specific furnace type, the melting process generally follows a structured workflow from solid raw material to liquid product ready for casting.

Stage 1: Charging

This is the initial loading phase. Raw materials, which can include scrap metal, ingots, and specific alloying elements, are carefully selected and placed into the furnace's crucible. The composition of the charge is calculated precisely to achieve the desired final alloy.

Stage 2: Melting

Once charged, the power is applied to the furnace. In an induction furnace, the electromagnetic field is activated, inducing eddy currents and heating the material to its liquefaction point. The process is monitored closely to manage the melting rate and energy consumption.

Stage 3: Refining

After the metal is fully molten, the refining stage begins. This critical step focuses on removing impurities and adjusting the chemical composition. For example, less dense impurities, known as slag, will float to the surface and can be skimmed off. This ensures the final metal meets strict quality specifications.

Stage 4: Pouring

Once the molten metal has reached the correct temperature and composition, it is poured out of the furnace. This is typically done by tilting the furnace body to transfer the liquid metal into a ladle, which then transports it to be poured into molds for solidification into a final shape.

Understanding the Trade-offs and Critical Components

While powerful, the melting process involves key variables and support systems that are crucial for successful and safe operation. Understanding these elements is essential for appreciating the technology's nuances.

Why Frequency Matters

The frequency of the alternating current used in an induction furnace is a critical parameter. Lower frequencies penetrate deeper into the metal charge, making them suitable for melting large pieces. Higher frequencies are better for smaller pieces or when a more vigorous stirring action is desired.

The Need for Cooling

The immense electrical currents flowing through the induction coil generate significant heat. To prevent the coil itself from melting, it is engineered as a hollow tube through which a water cooling system continuously circulates fluid, dissipating heat and maintaining operational integrity.

Process Variations

While induction melting is widespread, other specialized furnaces exist for specific applications. A rotary furnace, for example, uses heat and centrifugal force to shape molten glass or low-melting-point alloys into precise parabolic shapes for lenses and mirrors.

Making the Right Choice for Your Goal

The specific approach to furnace melting is always dictated by the desired outcome, whether it's material purity, production speed, or a specialized final product.

- If your primary focus is high purity and alloy consistency: The vacuum induction melting process is superior, as it performs the stages in a vacuum to prevent contamination from the atmosphere.

- If your primary focus is energy efficiency and speed for common metals: A standard medium-frequency induction furnace offers an optimal balance of rapid melting cycles and clean operation.

- If your primary focus is creating highly specialized geometric shapes: A purpose-built method, such as rotary furnace melting, is necessary to achieve results not possible through standard casting.

Ultimately, the furnace melting process transforms raw materials into precisely engineered liquid metal, ready to become the foundation for countless finished products.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Charging | Loading solid metal (scrap, ingots) into the crucible | Prepare the raw material for melting |

| 2. Melting | Applying electromagnetic induction to generate internal heat | Liquefy the metal charge rapidly and uniformly |

| 3. Refining | Skimming slag and adjusting chemical composition | Remove impurities and achieve target alloy specs |

| 4. Pouring | Tilting furnace to transfer molten metal to a ladle | Prepare the liquid metal for casting into final shapes |

Ready to achieve superior metal purity and production efficiency in your lab or foundry?

KINTEK specializes in high-performance lab equipment, including advanced melting furnace solutions. Our expertise ensures you get the right technology—whether for high-purity vacuum induction melting or energy-efficient standard models—to meet your specific material goals.

Contact our experts today to discuss how a KINTEK melting furnace can transform your metal processing workflow, enhance alloy consistency, and boost your operational output.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity