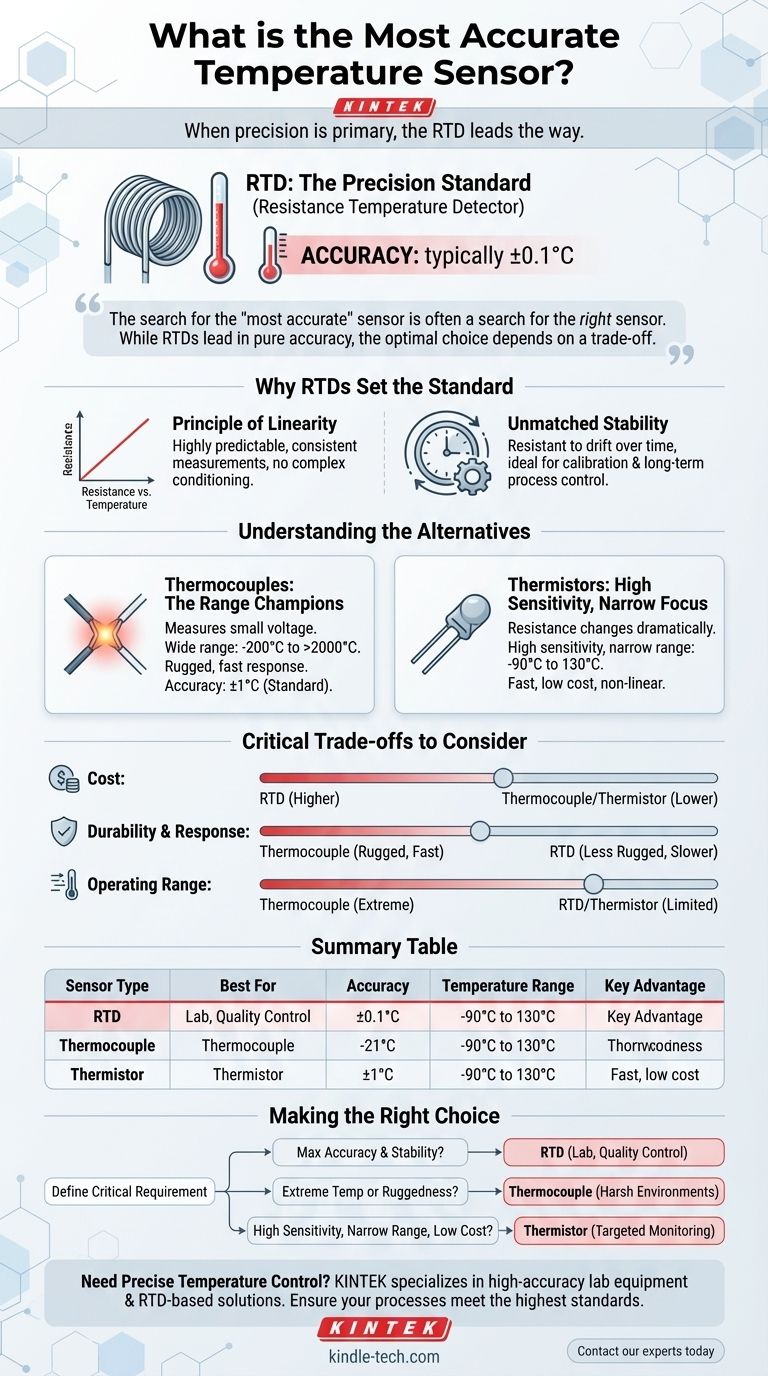

When precision is the primary concern, the Resistance Temperature Detector (RTD) is the most accurate temperature sensor for most industrial and scientific applications. RTDs are engineered for stability and linearity, typically achieving an accuracy of ±0.1°C. This stands in contrast to the more common ±1°C accuracy found in standard thermocouples and thermistors.

The search for the "most accurate" sensor is often a search for the right sensor. While RTDs lead in pure accuracy, the optimal choice always depends on a calculated trade-off between accuracy, operating temperature range, and cost.

Why RTDs Set the Standard for Accuracy

The superior performance of an RTD is not accidental; it is a direct result of its material properties and construction. It operates on a highly predictable and stable physical principle.

The Principle of Linearity

An RTD functions by measuring the change in electrical resistance of a pure metal, most commonly platinum. This relationship between temperature and resistance is exceptionally linear and well-documented.

This linearity means the sensor provides consistent and repeatable measurements across its operating range without the complex signal conditioning required by other sensor types.

Unmatched Stability

Because RTDs are built from pure, stable metals, they are highly resistant to drift over time. This ensures that a measurement taken today will be the same as a measurement taken under the same conditions years from now, making them ideal for calibration and critical process control.

Understanding the Alternatives

While RTDs are the most accurate, they are not the only option. Thermocouples and thermistors serve critical roles where different performance characteristics are more important.

Thermocouples: The Range Champions

Thermocouples operate by measuring the small voltage generated when two dissimilar metals are joined at a sensing junction. Their primary advantage is an incredibly wide temperature range, capable of measuring from cryogenic levels to well over 2000°C.

While most standard thermocouples are less accurate than RTDs, some specialized versions are engineered to match RTD-level precision in certain ranges.

Thermistors: High Sensitivity, Narrow Focus

Thermistors are semiconductor devices whose resistance changes dramatically with temperature. They offer extremely high sensitivity within a limited temperature range.

This makes them excellent for applications requiring a rapid response to small temperature changes, but their non-linear nature and narrower operating window make them unsuitable for broad-range, high-accuracy measurements.

The Critical Trade-offs to Consider

Choosing a sensor based on accuracy alone can lead to poor system design. You must weigh the benefits of an RTD against its practical limitations.

Cost

The high-purity platinum and careful construction required for an RTD make it a more expensive component compared to the simpler and more common thermocouple or thermistor.

Durability and Response Time

Thermocouples are generally more rugged and resistant to vibration than RTDs. Their small sensing junction also allows them to respond to temperature changes much more quickly.

Operating Range

No sensor can match the sheer temperature range of a thermocouple. If your application involves extreme heat or cold, a thermocouple is often the only viable choice, regardless of its lower base accuracy.

Making the Right Choice for Your Application

To select the correct sensor, you must first define your most critical operational requirement.

- If your primary focus is maximum accuracy and stability: Choose an RTD for applications like laboratory work, custody transfer, or quality-critical process control where fractions of a degree are significant.

- If your primary focus is measuring extreme temperatures or ruggedness: A thermocouple is the superior choice, providing reliable measurements in harsh environments where other sensors would fail.

- If your primary focus is high sensitivity in a specific, narrow range at a low cost: A thermistor provides an excellent and economical solution for targeted temperature monitoring and control.

Ultimately, the best sensor is the one that delivers the required performance for your specific task within your operational constraints.

Summary Table:

| Sensor Type | Best For | Accuracy | Temperature Range | Key Advantage |

|---|---|---|---|---|

| RTD | Maximum Accuracy & Stability | ±0.1°C | -200°C to 600°C | Superior Linearity & Long-Term Stability |

| Thermocouple | Extreme Temperatures & Ruggedness | ±1°C (Standard) | -200°C to >2000°C | Wide Range & Durability |

| Thermistor | High Sensitivity in Narrow Range | Varies | -90°C to 130°C | High Sensitivity & Low Cost |

Need precise temperature control for your lab? KINTEK specializes in high-accuracy lab equipment and consumables, including RTD-based solutions for critical applications. Ensure your processes meet the highest standards of accuracy and reliability. Contact our experts today to find the perfect temperature sensor for your specific needs!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Bomb Type Probe for Steelmaking Production Process

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Battery Lab Applications

- Oxygen Probe to Measure Temperature and Active Oxygen Content in Molten Steel

People Also Ask

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance