At its core, the need for wear-resistant coatings is economic and functional. They are applied to protect a component’s surface from mechanical damage, such as friction and abrasion. This protection dramatically extends the operational life of the part, preventing costly failures, reducing downtime, and ultimately lowering the total cost of ownership.

The fundamental strategy is to decouple a component's bulk properties from its surface properties. This allows you to use a cost-effective, strong core material while creating an extremely durable, high-performance surface that bears the brunt of all wear and tear.

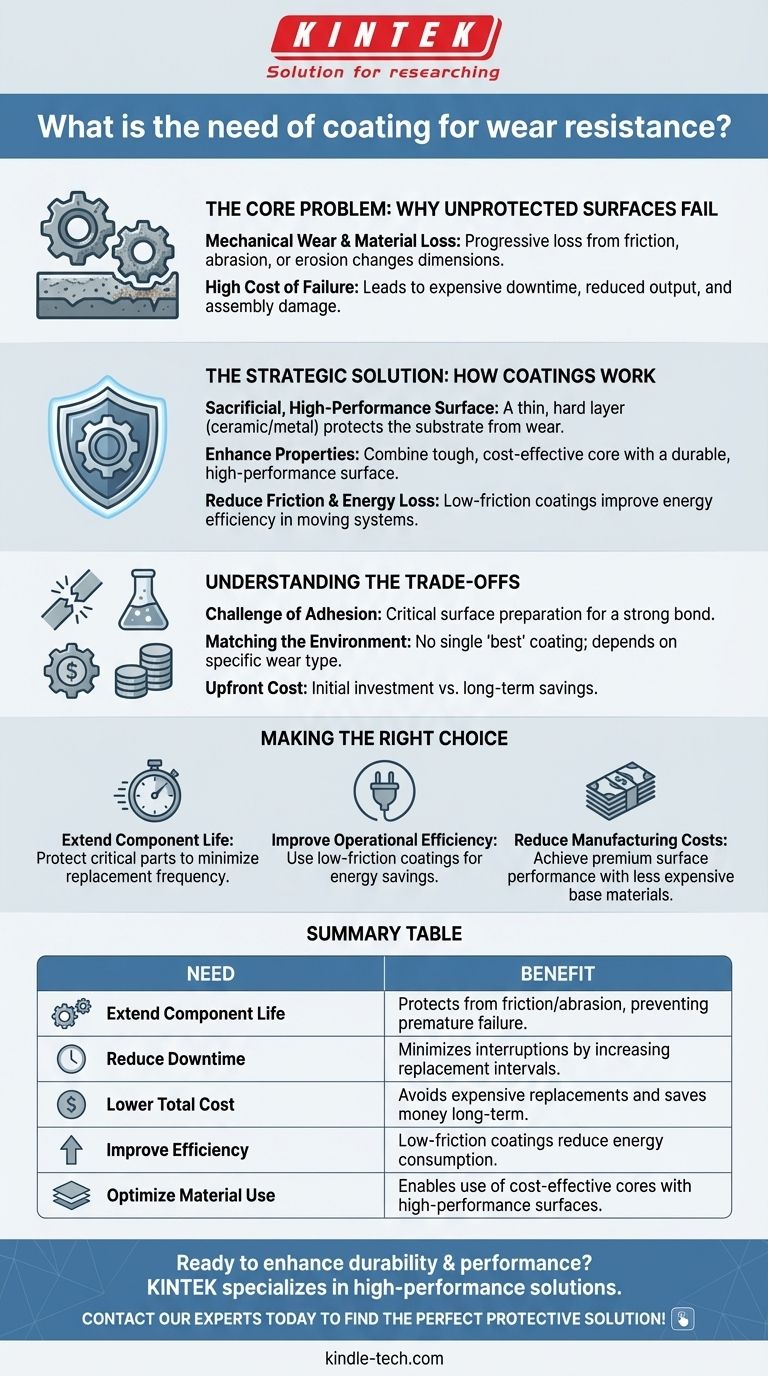

The Core Problem: Why Unprotected Surfaces Fail

In any mechanical system, interacting surfaces are the first point of failure. Understanding the nature of this failure is key to appreciating the role of coatings.

Mechanical Wear and Material Loss

Wear is the progressive loss of material from a surface due to mechanical action. This can be caused by friction between two moving parts, abrasion from hard particles, or erosion from high-velocity fluids.

Over time, this material loss changes the critical dimensions and tolerances of a component. This degradation inevitably leads to a decline in performance and eventual failure.

The High Cost of Component Failure

When a part wears out, the consequences extend beyond the cost of a replacement. It often leads to expensive operational downtime, reduced manufacturing output, and potential damage to adjacent components in the assembly.

How Coatings Provide a Strategic Solution

Instead of making an entire component out of an expensive, highly wear-resistant material, coatings provide a more targeted and economical solution.

Creating a Sacrificial, High-Performance Surface

A coating acts as a protective shield. It is a thin layer of specialized material—often a ceramic or hard metal—that is harder and more durable than the underlying component, known as the substrate.

This sacrificial layer endures the abrasive and frictional forces, preserving the integrity and dimensions of the core component.

Enhancing Properties Beyond the Base Material

Coatings allow you to combine the best properties of different materials. You can use a tough, inexpensive steel for the body of a part and apply a thin ceramic coating to give it a super-hard, low-friction surface.

This is common in applications like ball valve hardware, water-jet nozzles, and textile machinery components, where the base part needs strength but the surface needs extreme hardness.

Reducing Friction and Energy Loss

Many wear-resistant coatings also have a very low coefficient of friction. By reducing the resistance between moving parts, these coatings can improve the overall energy efficiency of a mechanical system, leading to lower power consumption.

Understanding the Trade-offs

While highly effective, coatings are not a universal solution. Their success depends on careful selection and application.

The Challenge of Adhesion

A coating is only as good as its bond to the substrate. Poor adhesion will cause the coating to chip or peel away, rendering it useless. The surface preparation and application process are critical to ensure a strong, permanent bond.

Matching the Coating to the Environment

There is no single "best" coating. The right choice depends entirely on the specific type of wear. A coating designed for high-abrasion environments might perform poorly in a situation involving high-impact or chemical corrosion.

The Upfront Cost

Applying a high-performance coating adds an initial cost to the component. This investment must be weighed against the long-term savings from extended part life and reduced downtime.

Making the Right Choice for Your Goal

The decision to use a coating should be driven by your primary operational objective.

- If your primary focus is extending component life: Use coatings as a protective barrier on critical parts to drastically reduce the frequency of replacement and minimize operational downtime.

- If your primary focus is improving operational efficiency: Select specialized low-friction coatings to reduce the energy consumption of moving systems and improve overall performance.

- If your primary focus is reducing manufacturing costs: Use coatings to achieve premium surface performance on components made from less expensive base materials, avoiding the high cost of exotic alloys.

Ultimately, wear-resistant coatings provide a powerful engineering tool to enhance durability and manage costs by placing protection precisely where it is needed most.

Summary Table:

| Need | Benefit |

|---|---|

| Extend Component Life | Protects surfaces from friction and abrasion, preventing premature failure. |

| Reduce Downtime | Minimizes operational interruptions by increasing time between part replacements. |

| Lower Total Cost | Avoids expensive replacements and damage to adjacent components, saving money long-term. |

| Improve Efficiency | Low-friction coatings can reduce energy consumption in moving systems. |

| Optimize Material Use | Allows use of cost-effective core materials with a high-performance surface layer. |

Ready to enhance your lab equipment's durability and performance? KINTEK specializes in high-performance lab equipment and consumables designed for longevity. Our expertise in wear-resistant solutions can help you extend the life of your critical components, reduce downtime, and optimize your operational costs. Contact our experts today to find the perfect protective solution for your laboratory needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- Is diamond coating worth it? Maximize Component Life and Performance

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer