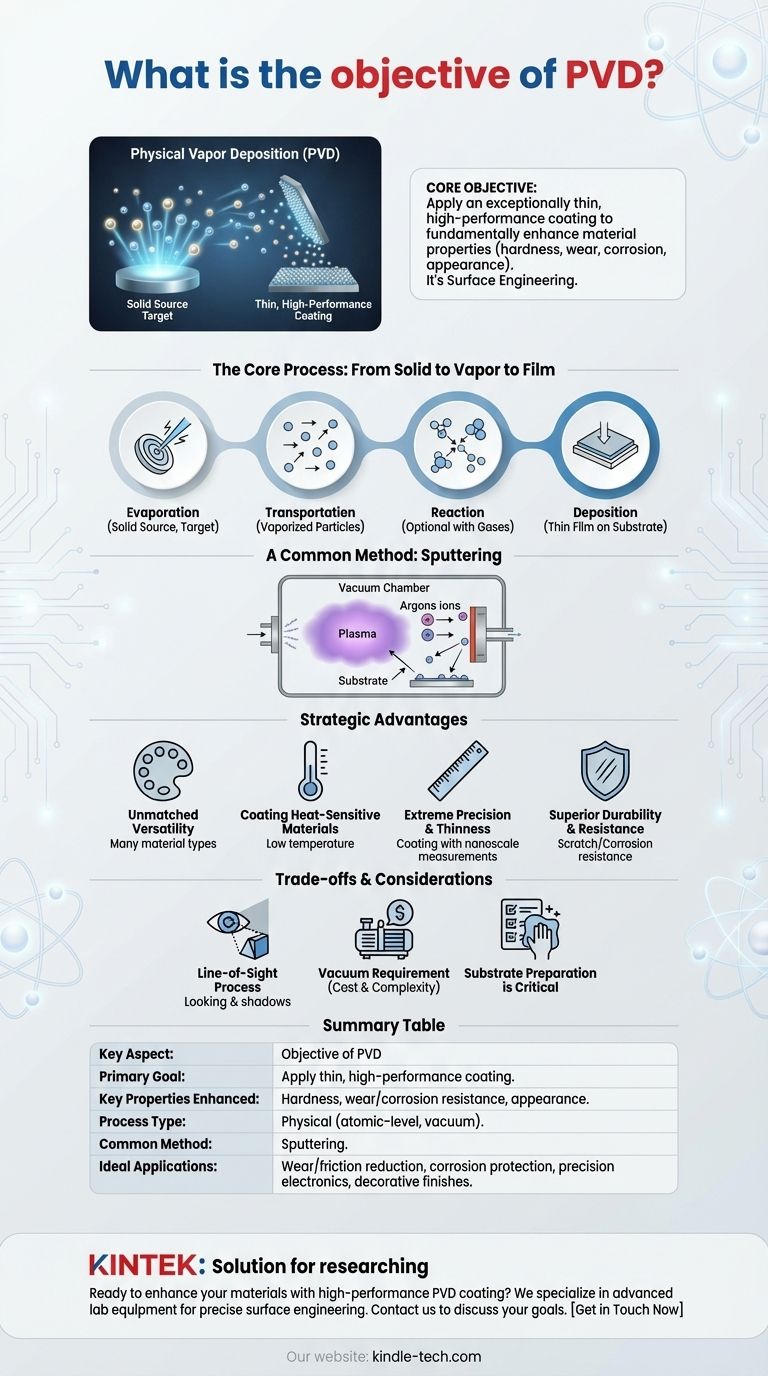

At its core, the objective of Physical Vapor Deposition (PVD) is to apply an exceptionally thin, high-performance coating onto a surface. This process is performed at an atomic level in a vacuum to fundamentally enhance a material's properties, such as its hardness, wear resistance, corrosion resistance, and appearance.

PVD is not merely a coating method; it is a surface engineering technique. Its primary goal is to grant a component new capabilities it does not inherently possess, transforming its surface into a more durable, functional, or aesthetically pleasing version of itself.

How PVD Achieves Its Goal: The Core Process

To understand the objective of PVD, you must first understand how it works. The process is a highly controlled physical transformation that occurs in four distinct stages: evaporation, transportation, reaction, and deposition.

From Solid to Vapor to Film

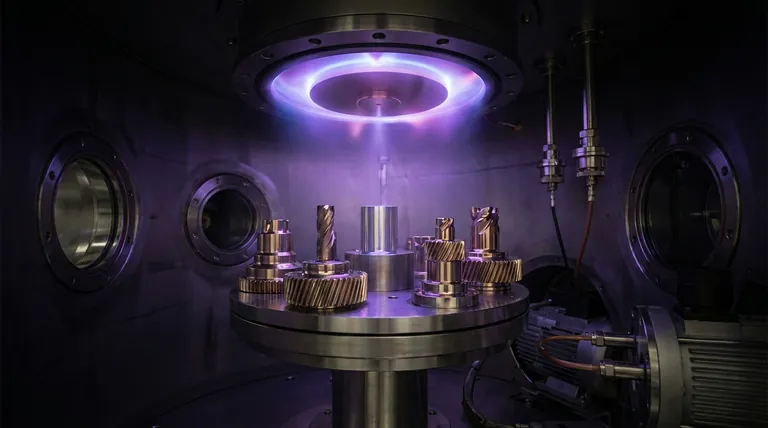

The PVD process begins with a solid source material, often called a "target." In a high-vacuum chamber, this material is bombarded with energy—for example, by a high-energy electron beam or ion bombardment—causing it to vaporize into individual atoms or molecules.

These vaporized particles then travel across the vacuum chamber and condense onto the substrate (the part being coated), forming a thin, dense, and highly adherent film.

A Purely Physical Transfer

In its most basic form, PVD is a physical process, not a chemical one. The coating material simply transitions from a solid state to a vapor state and back to a solid film on the part's surface.

However, reactive gases like nitrogen or oxygen can be introduced into the chamber. The vaporized metal atoms react with these gases to form ceramic compounds like nitrides or oxides directly on the substrate, creating exceptionally hard and durable coatings.

A Common Method: Sputtering

Sputtering is one of the most common and versatile methods used to vaporize the target material in PVD.

An inert gas, typically argon, is introduced into the vacuum chamber and energized to create a plasma. A high voltage is applied to the target material, causing the positive argon ions from the plasma to accelerate and collide with it, knocking off atoms like microscopic billiard balls. These "sputtered" atoms then travel to and deposit on the substrate.

The Strategic Advantages of Using PVD

Engineers and designers choose PVD because it offers a unique combination of versatility, precision, and performance that other coating methods cannot match.

Unmatched Material Versatility

PVD can deposit a vast range of materials. This includes pure metals, alloys, and a wide variety of hard ceramic compounds such as nitrides, carbides, and oxides, offering a massive palette for engineering specific surface properties.

Coating Heat-Sensitive Materials

Because the process can be conducted at relatively low temperatures, PVD is suitable for coating substrates that cannot withstand high heat. This makes it possible to apply hard, durable coatings to materials like plastics and other polymers.

Extreme Precision and Thinness

The deposition occurs on an atomic level, allowing for incredibly thin and uniform coatings, often just a few nanometers thick. This precision ensures that the critical dimensions and surface finish of a component are not significantly altered.

Superior Durability and Resistance

PVD coatings are known for their exceptional hardness, which provides superior resistance to scratching and wear. The films are also very dense and non-porous, creating an excellent barrier against corrosion and oxidation.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Being objective requires understanding its limitations.

It's a Line-of-Sight Process

The vaporized coating material travels in a straight line from the target to the substrate. This makes it challenging to evenly coat complex, three-dimensional shapes or the inside surfaces of parts without sophisticated fixtures and part rotation.

Vacuum Requirement Drives Cost and Complexity

PVD systems require a high-vacuum environment, which necessitates specialized and often expensive equipment. The process of pumping down the chamber also makes it slower and less suitable for high-volume, low-cost parts compared to methods like electroplating.

Substrate Preparation is Critical

The adhesion and quality of the final coating are highly dependent on the cleanliness of the substrate. Any surface contamination will lead to poor bonding and potential coating failure, requiring rigorous pre-treatment and handling protocols.

Making the Right Choice for Your Goal

PVD is the correct choice when your primary objective is to fundamentally upgrade the surface performance of a component with precision.

- If your primary focus is extreme wear or friction reduction: PVD is the leading choice for applying hard ceramic coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC).

- If your primary focus is corrosion or chemical resistance: PVD provides a dense, non-porous barrier ideal for protecting components in harsh environments.

- If your primary focus is high-precision electronics or optics: The atomic-level control of PVD allows for the creation of exceptionally thin, pure, and uniform functional layers.

- If your primary focus is a durable decorative finish: PVD offers a wide range of colors that are far more resistant to chipping, fading, and tarnishing than traditional paint or plating.

Ultimately, the objective of PVD is to give you precise control over the surface properties of your materials.

Summary Table:

| Key Aspect | Objective of PVD |

|---|---|

| Primary Goal | Apply a thin, high-performance coating to enhance material properties. |

| Key Properties Enhanced | Hardness, wear resistance, corrosion resistance, appearance. |

| Process Type | Physical (atomic-level transfer in a vacuum). |

| Common Method | Sputtering. |

| Ideal Applications | Wear/friction reduction, corrosion protection, precision electronics, durable decorative finishes. |

Ready to enhance your materials with a high-performance PVD coating?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise surface engineering. Our expertise can help you achieve superior hardness, wear resistance, and corrosion protection for your components.

We help you:

- Apply ultra-thin, durable coatings to extend component life.

- Improve material performance for demanding applications.

- Select the right PVD solution for your specific needs.

Contact us today to discuss how our PVD solutions can transform your materials. Let's achieve your surface engineering goals together!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition