In essence, Hot Isostatic Pressing (HIP) is a manufacturing process that subjects components to both high temperature and extreme, uniform pressure. By applying an inert gas like argon at elevated temperatures inside a sealed vessel, HIP fundamentally improves a material's properties by eliminating internal voids and creating a fully dense structure.

The core value of Hot Isostatic Pressing lies in its ability to use uniform, gas-based pressure to collapse and heal internal defects—like pores in castings or voids between powder particles—without distorting the component's external shape. This results in materials with superior strength, ductility, and fatigue resistance.

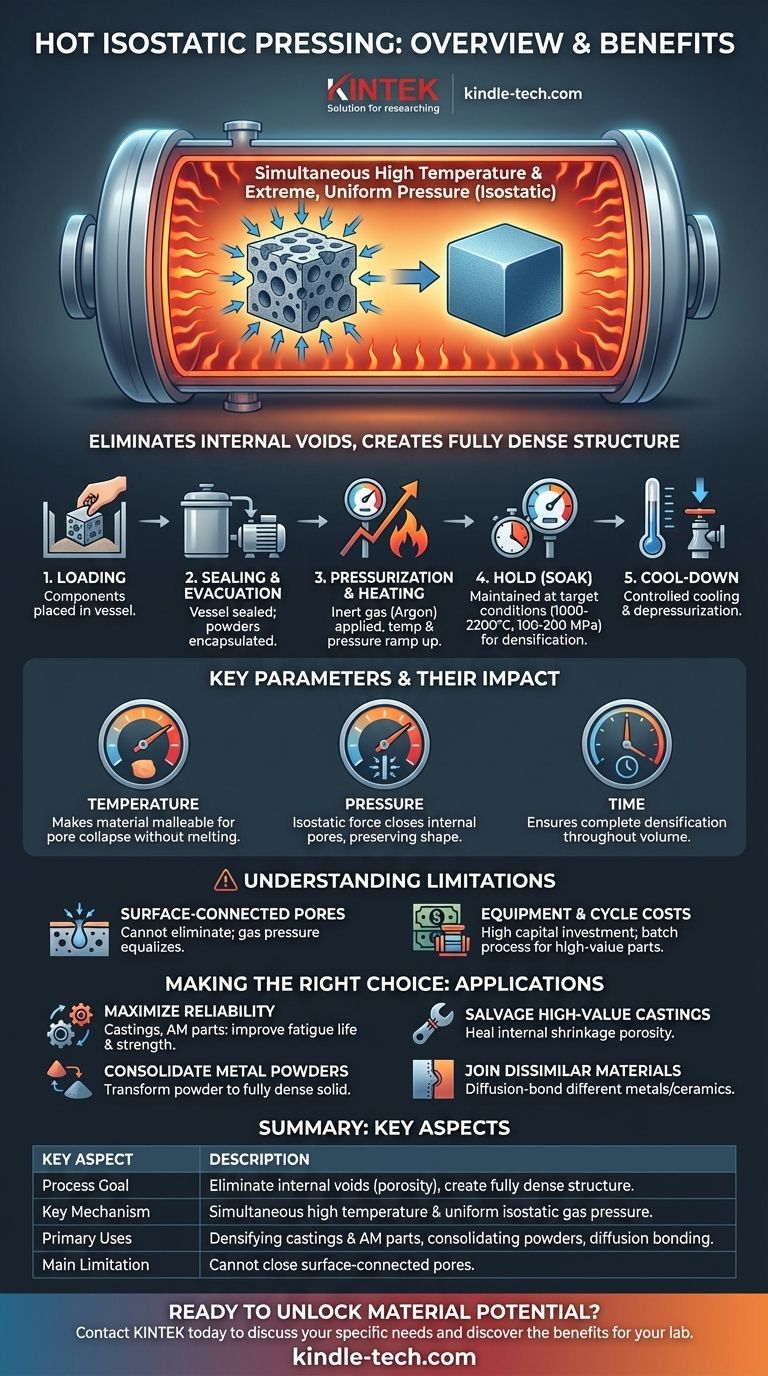

How Hot Isostatic Pressing Works: The Core Mechanism

Hot Isostatic Pressing combines three key elements—temperature, pressure, and an inert atmosphere—to achieve densification or bonding.

The Fundamental Principle

The process operates by heating a material to a point where it becomes soft and malleable, but typically below its melting point. Simultaneously, immense pressure is applied, providing the force needed to collapse any internal porosity.

The Role of Inert Gas

An inert gas, most commonly argon, is used as the pressure-transmitting medium. It is chosen because it will not chemically react with the material being processed, even at extreme temperatures. This gas fills the chamber and exerts uniform, or isostatic, pressure on every surface of the part.

The Process Step-by-Step

A typical HIP cycle is precisely controlled by computers and follows a clear sequence:

- Loading: Components are placed inside the HIP vessel's heating chamber.

- Sealing & Evacuation: The vessel is sealed. For processing powders, they are first sealed in a gas-tight container under a vacuum.

- Pressurization & Heating: The chamber is filled with inert gas to an initial pressure, and the furnace begins heating. Both temperature and pressure ramp up according to a pre-programmed cycle.

- Hold (Soak): The component is held at the target temperature (1000–2200°C) and pressure (100–200 MPa) for a specified duration to allow for complete densification.

- Cool-Down: The system undergoes a controlled cooling and depressurization phase, ensuring the parts are safe to handle upon removal.

Key Parameters and Their Impact

The effectiveness of the HIP process depends on the precise control of its main variables, which are tailored to the specific material and desired outcome.

Temperature

The temperature is chosen to make the material soft enough for plastic deformation to occur. This allows the internal voids to collapse under pressure without melting the component.

Pressure

High isostatic pressure provides the driving force for densification. Because the pressure is applied equally from all directions, it closes internal pores without changing the part's net shape or dimensions.

Time

The duration of the cycle, particularly the hold time at peak temperature and pressure, ensures that the densification process completes throughout the entire volume of the material, delivering reliable and repeatable results.

Understanding the Trade-offs and Limitations

While powerful, HIP is not a universal solution. Understanding its limitations is critical for its successful application.

Inability to Close Surface-Connected Pores

HIP can only eliminate internal, isolated voids. If a pore is connected to the component's surface, the high-pressure gas will simply fill the pore, equalizing the pressure and preventing it from collapsing. This is why powders must be encapsulated in a sealed container before processing.

Equipment and Cycle Costs

HIP systems are highly specialized and represent a significant capital investment. The process is a batch operation, not continuous, which can contribute to higher costs per part. It is therefore most often reserved for high-value components where ultimate performance is non-negotiable.

Not a Corrective Process for Shape

While HIP excels at preserving the near-net shape of a component, it cannot fix significant geometrical errors. Parts must already be manufactured to their intended shape and dimensions before undergoing the HIP cycle.

Making the Right Choice for Your Goal

Consider Hot Isostatic Pressing when your material performance requirements justify the investment.

- If your primary focus is maximizing the reliability of critical components: Use HIP to eliminate internal defects in castings or additively manufactured parts, drastically improving fatigue life and impact strength.

- If your primary focus is salvaging high-value castings: Apply HIP to heal internal shrinkage porosity, upgrading the material integrity of parts that might otherwise be scrapped.

- If your primary focus is producing dense parts from metal powders: Use HIP as a consolidation step to transform metal powders into a fully dense solid with mechanical properties that can rival wrought materials.

- If your primary focus is joining dissimilar materials: Leverage HIP to diffusion-bond different metals or ceramics, creating a robust, void-free metallurgical joint that is difficult to achieve with other methods.

Ultimately, Hot Isostatic Pressing provides a powerful tool for achieving a level of material integrity and performance that is often unattainable through other manufacturing methods.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Eliminate internal voids (porosity) to create a fully dense material structure. |

| Key Mechanism | Simultaneous application of high temperature and uniform, isostatic gas pressure. |

| Primary Uses | Densifying castings & additive manufacturing parts, consolidating metal powders, diffusion bonding. |

| Main Limitation | Cannot close pores that are connected to the component's surface. |

Ready to unlock the full potential of your materials?

Hot Isostatic Pressing (HIP) can transform your high-value components—from castings to 3D-printed parts—by delivering unparalleled density, strength, and fatigue resistance. KINTEK specializes in advanced lab equipment and consumables, providing solutions for laboratories seeking to enhance material performance and reliability.

Let our experts help you determine if HIP is the right process for your application. Contact KINTEL today to discuss your specific needs and discover the benefits for your lab.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is spark plasma sintering of materials? A Guide to High-Speed, High-Performance Densification

- How does the pressure loading system of a hot pressing sintering furnace influence Ti-22Al-25Nb powders?

- What is the temperature of hot isostatic pressing? Achieve Full Density for Critical Components

- What are the advantages of hot press? Achieve Superior Bonding and Material Densification

- What role does a Vacuum Hot Press perform in the densification of Mg3Sb2? Achieve 96%+ Density with VHP

- What technical advantages do hot pressing or SPS furnaces provide? Achieving Dense, High-Conductivity Electrolytes

- Why is it necessary to use graphite paper or graphite spacers for hot pressing? Protect Your Molds & Improve Samples

- What core challenges does a vacuum hot press furnace address? Achieve Superior WCp/Cu FGM Structural Integrity