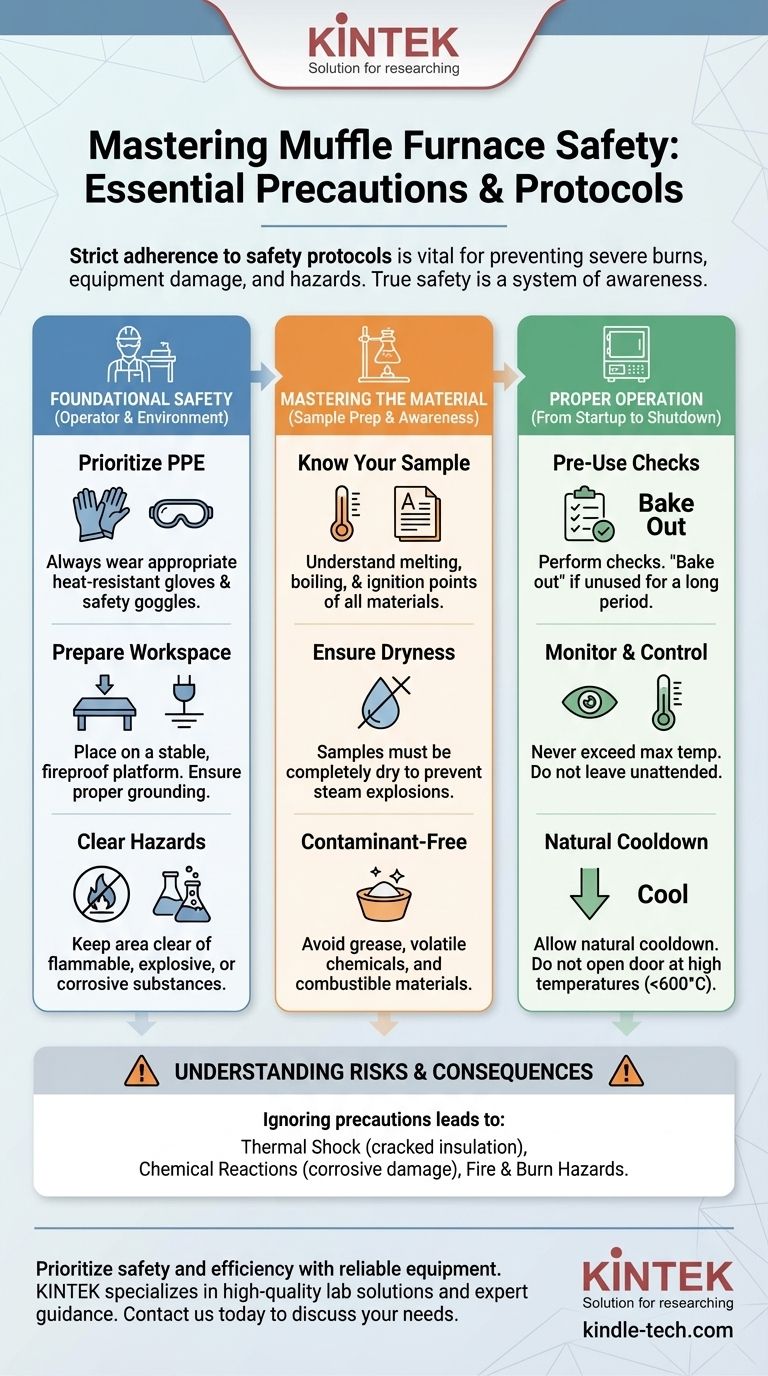

Using a muffle furnace requires strict adherence to safety protocols. The core precautions involve wearing appropriate Personal Protective Equipment (PPE), thoroughly understanding the properties of the materials you are heating, maintaining a safe and clean operating environment, and following precise procedures for startup, operation, and shutdown. These steps are essential to prevent severe burns, equipment damage, and potential fires or explosions.

The safe operation of a muffle furnace is not a single action but a system of awareness. True safety comes from understanding the interplay between the operator, the sample material, and the furnace itself at every stage of the process.

Foundational Safety: The Operator and the Environment

Before you even turn the furnace on, you must establish a safe foundation for your work. This involves protecting yourself and preparing the physical space.

Prioritize Personal Protective Equipment (PPE)

You must wear protective gear to shield yourself from the extreme heat. Always use heat-resistant gloves and safety goggles. The type of glove required will depend on the furnace's operating temperature, so ensure yours are rated appropriately.

Prepare the Workspace

The furnace should be placed on a stable, fireproof platform, like a cement bench. Ensure it is properly grounded with the correct plugs, sockets, and fuses.

Keep the area immediately surrounding the furnace completely clear of flammable, explosive, or corrosive substances. The furnace jacket becomes extremely hot during operation and can ignite nearby materials.

Ensure Professional Operation

Muffle furnaces should only be operated by trained professionals. If you are unfamiliar with a specific model, seek out training before attempting to use it.

Mastering the Material: Sample Preparation and Awareness

What you put inside the furnace is the single greatest variable. Improperly prepared samples are a primary cause of accidents and equipment damage.

Know Your Sample's Properties

It is crucial to know the melting, boiling, and ignition points of all materials being placed in the furnace. Never heat a substance in an open container if you are unsure of how it will react to extreme temperatures.

Ensure Samples Are Dry and Contaminant-Free

Confirm that samples are completely dry before heating. The sudden vaporization of trapped moisture can cause a small-scale explosion, damaging the sample and the furnace.

Likewise, ensure samples are free from combustible materials, grease, or volatile chemicals. These can release corrosive gases that destroy the furnace's heating elements or create a fire hazard.

Handle Special Materials Correctly

When heating materials known to produce volatile or corrosive gases, they should be placed in a sealed container with proper ventilation.

For glassware like Pyrex, cover any open ends with aluminum foil to manage pressure changes. Very small items should also be wrapped in foil to prevent them from being lost or falling into crevices.

Proper Furnace Operation: From Startup to Shutdown

A disciplined, step-by-step operational procedure is non-negotiable for safety and for protecting the longevity of the equipment.

Pre-Use Checks and Startup

If a furnace has been unused for a long time, it may have absorbed moisture. It must be "baked out" by running it at a low temperature for a period to dry it out before ramping up to high temperatures.

Managing Temperature and Monitoring

Never exceed the maximum rated temperature of the furnace, as this can damage the heating elements. Also, avoid operating at the maximum temperature for extended periods.

The furnace must be monitored throughout its use. Do not leave it running unattended, especially overnight, in case of a control system failure that could lead to a dangerous overheating event. Watch for abnormalities like smoke or unusual noises and shut the system down immediately if they occur.

The Shutdown and Cooldown Protocol

After the heating cycle is complete, turn off the main power. Allow the furnace to cool down naturally.

Do not open the door while the furnace is at a very high temperature (a general rule is to wait until it is below 600°C). Opening the door can cause thermal shock, cracking the refractory insulation, and poses a severe burn risk. Similarly, never pull the thermocouple out suddenly from a hot furnace, as this can cause the protective jacket to burst.

Understanding the Risks and Trade-offs

Following procedures is easier when you understand the consequences of ignoring them. The primary risks are thermal, chemical, and electrical.

The Risk of Thermal Shock

Rapid temperature changes are destructive to a muffle furnace. Opening the door too soon or pulling out components causes thermal shock, which can crack the delicate ceramic insulation (refractory) that lines the chamber. This is why a slow, natural cooldown is essential.

The Danger of Chemical Reactions

Heating unknown or contaminated substances is a significant gamble. Fats and plastics can release corrosive gases that will permanently damage the heating elements, dramatically shortening the furnace's lifespan. Trapped water or reactive chemicals can create pressure, turning your sample into a projectile.

The Fire and Burn Hazard

The risk of fire is constant. The exterior of the furnace becomes hot enough to ignite common lab materials. More specifically, if using quenching oils, they can easily catch fire if contaminated with water or overheated. The most immediate danger is always the risk of severe burns from touching the furnace or handling hot samples without proper PPE.

Making the Right Choice for Your Work

Your focus dictates which precautions are most critical in the moment.

- If your primary focus is personal safety: Always wear appropriate PPE, never open a hot furnace, and keep the area clear of all flammable materials.

- If your primary focus is experimental integrity: Know the thermal and chemical properties of your sample and ensure it is absolutely clean and dry before heating.

- If your primary focus is equipment longevity: Always follow proper startup and natural cooldown procedures, and prevent corrosive vapors from contaminating the heating elements.

Ultimately, safety in the lab is a deliberate practice, not a checklist to be rushed.

Summary Table:

| Precaution Category | Key Actions |

|---|---|

| Personal & Environmental Safety | Wear heat-resistant gloves and safety goggles. Place furnace on a stable, fireproof surface. Keep area clear of flammables. |

| Sample Preparation | Know material melting/boiling points. Ensure samples are completely dry and contaminant-free. Use sealed containers for volatile materials. |

| Furnace Operation | Perform pre-use checks. Never exceed max temperature. Monitor during use; do not leave unattended. Allow for natural cooldown. |

| Primary Risks | Thermal shock, chemical reactions releasing corrosive gases, fire hazards, and severe burns. |

Ensure your laboratory operates with the highest standards of safety and efficiency. The correct procedures and reliable equipment are fundamental to protecting your team and your research. KINTEK specializes in providing high-quality lab equipment, including muffle furnaces, and the expert guidance needed for their safe operation. Contact us today to discuss your specific laboratory needs and how we can support your success. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature accuracy of a muffle furnace? Achieve Precise and Uniform Heating

- What are the advantages of a muffle furnace? Achieve Unmatched Purity and Precision in Your Lab

- What is the inside of a muffle furnace? Discover the Key Components for Precise High-Temperature Processing

- What is the temperature of a muffle furnace? It's Not a Single Number—Find Your Perfect Range

- Can a muffle furnace be used for pyrolysis? How to adapt it for oxygen-free thermal decomposition