The operating pressure for Chemical Vapor Deposition (CVD) is not a single value but spans a wide range from near-vacuum conditions (a few Torr) to pressures at or above atmospheric levels. The specific pressure used is a defining characteristic of the CVD technique, as it fundamentally dictates the deposition mechanism, processing temperature, and resulting film quality.

The core takeaway is that pressure in CVD is a critical control parameter. The choice between low-pressure and atmospheric-pressure techniques represents a fundamental trade-off between deposition rate, equipment complexity, and the final properties of the deposited film, such as its uniformity and purity.

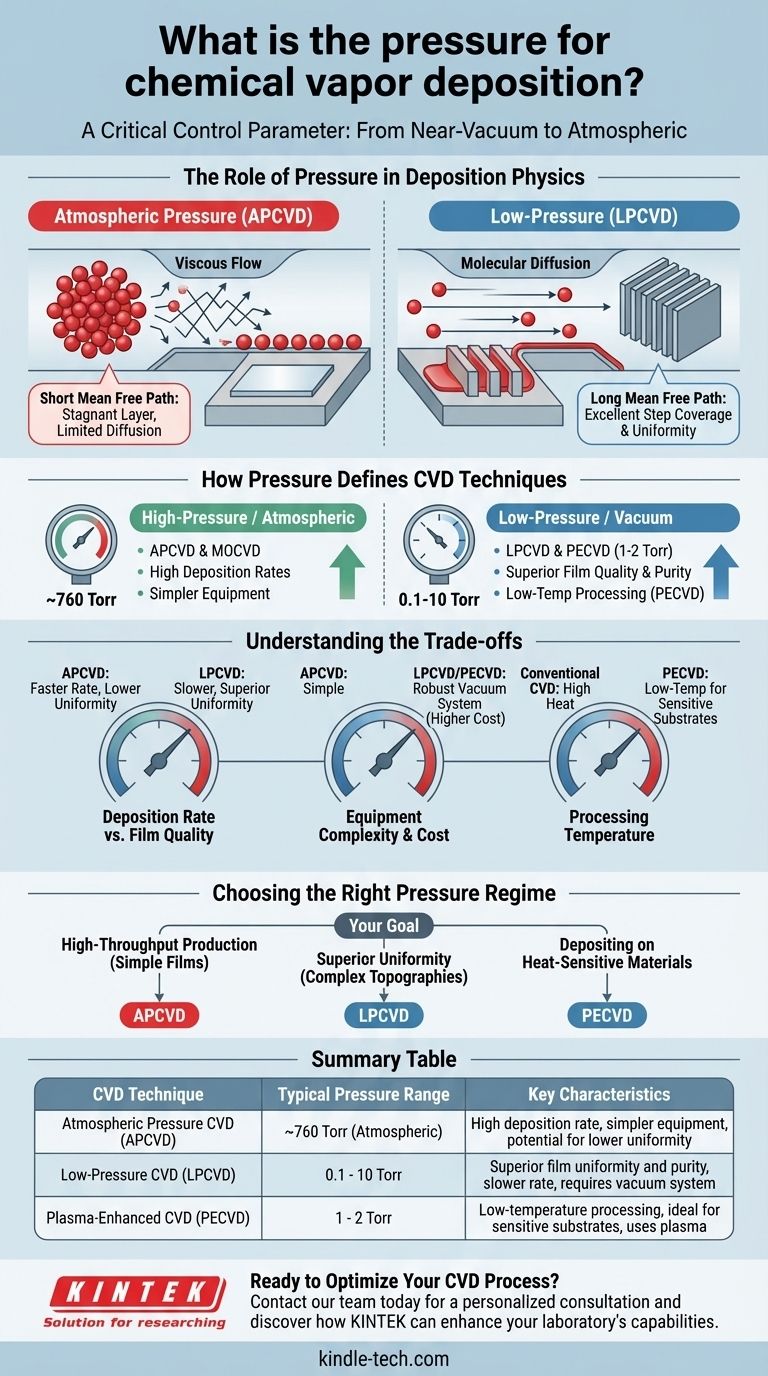

The Role of Pressure in Deposition Physics

Pressure directly controls the concentration of precursor gas molecules within the reaction chamber. This, in turn, dictates how those molecules travel and interact with the substrate, a concept known as the mean free path.

Atmospheric Pressure CVD (APCVD)

At or near atmospheric pressure, the concentration of gas molecules is high. This results in a very short mean free path, meaning molecules collide with each other frequently.

Gas transport is dominated by viscous flow, creating a stagnant boundary layer of gas just above the substrate surface. Precursors must diffuse through this layer to reach the surface, which can limit the process.

Low-Pressure CVD (LPCVD)

At low pressures (typically a few Torr), the gas is much less dense. This creates a very long mean free path, and gas molecules collide with the chamber walls and substrate far more often than with each other.

Here, transport is dominated by molecular diffusion. This allows precursor gases to reach and coat all surfaces of complex, three-dimensional structures much more evenly.

How Pressure Defines Common CVD Techniques

The required pressure regime is a primary way to classify different CVD methods. Each is optimized for different outcomes.

High-Pressure and Atmospheric Methods

Techniques like Atmospheric Pressure CVD (APCVD) and Metalorganic CVD (MOCVD) operate at or near standard atmospheric pressure.

These processes are valued for their high deposition rates and simpler equipment design, as they do not require extensive vacuum systems.

Low-Pressure and Vacuum Methods

Low-Pressure CVD (LPCVD) operates in a vacuum, typically in the range of a few Torr. This method is chosen when film quality is paramount.

Plasma-Enhanced CVD (PECVD) is a specific type of low-pressure process, often running between 1-2 Torr. The use of a plasma allows for significantly lower substrate temperatures (200-400°C) compared to traditional CVD (~1000°C).

Understanding the Trade-offs

Choosing a pressure regime is not arbitrary; it involves a clear set of engineering compromises based on the desired outcome.

Deposition Rate vs. Film Quality

Higher pressure (APCVD) generally leads to a faster deposition rate. However, this can come at the cost of lower film uniformity and a higher chance of gas-phase reactions creating unwanted particles.

Lower pressure (LPCVD) results in a slower process but yields films with superior uniformity, purity, and step coverage (the ability to coat sharp features evenly).

Equipment Complexity and Cost

APCVD systems can be relatively simple. In contrast, LPCVD and PECVD require robust vacuum systems, including pumps and pressure controllers, which increases the equipment's cost and complexity.

Processing Temperature

The most significant trade-off involves temperature. While conventional CVD requires very high heat, low-pressure techniques like PECVD allow for deposition on temperature-sensitive substrates (like plastics or certain electronics) that would be damaged by high-temperature processes.

Choosing the Right Pressure Regime for Your Application

Your final material requirements should dictate the CVD process and its corresponding pressure.

- If your primary focus is high-throughput production of simple films: An atmospheric pressure technique like APCVD is often the most cost-effective choice.

- If your primary focus is superior uniformity and coating complex topographies: A low-pressure technique like LPCVD is the standard for achieving high-quality, conformal films.

- If your primary focus is depositing films on heat-sensitive materials: A low-pressure, low-temperature technique like PECVD is the necessary solution.

Ultimately, pressure is the primary lever you can pull to tune the CVD environment for your specific material and application goals.

Summary Table:

| CVD Technique | Typical Pressure Range | Key Characteristics |

|---|---|---|

| Atmospheric Pressure CVD (APCVD) | ~760 Torr (Atmospheric) | High deposition rate, simpler equipment, potential for lower uniformity. |

| Low-Pressure CVD (LPCVD) | 0.1 - 10 Torr | Superior film uniformity and purity, slower rate, requires vacuum system. |

| Plasma-Enhanced CVD (PECVD) | 1 - 2 Torr | Low-temperature processing, ideal for sensitive substrates, uses plasma. |

Ready to Optimize Your CVD Process?

The right pressure regime is critical for achieving your desired film properties, whether you prioritize high throughput, exceptional uniformity, or low-temperature deposition on sensitive materials.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal CVD solution—from robust LPCVD systems to versatile PECVD reactors—to meet your specific research and production goals.

Contact our team today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings