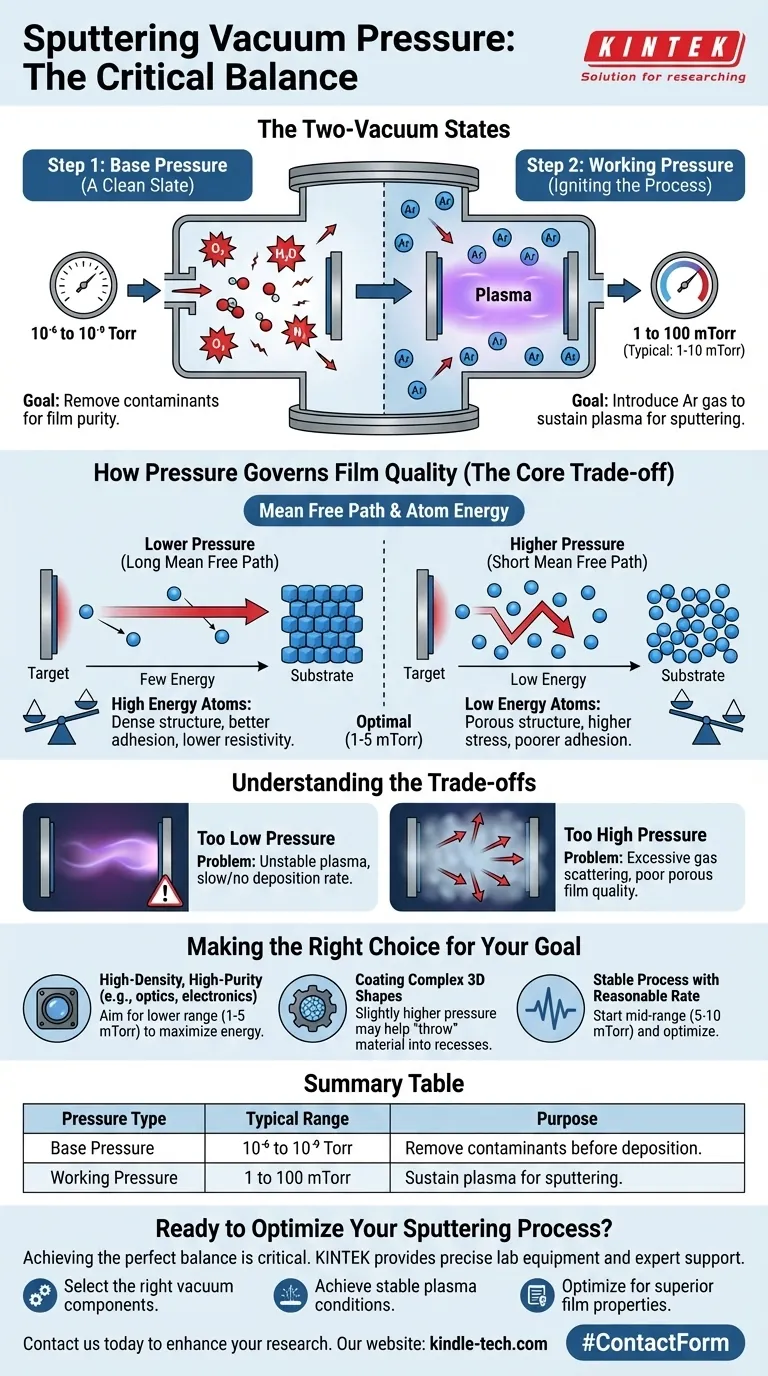

Critically, there is not one single pressure for sputtering, but rather two distinct pressure regimes that are essential for the process: a very low base pressure to ensure cleanliness and a higher working pressure to enable the sputtering itself. The working pressure, which is what most people refer to, typically falls within the range of 1 to 100 millitorr (mTorr), with many common processes operating between 1 and 10 mTorr.

The core challenge in sputtering is finding the optimal working pressure. It must be high enough to sustain a stable plasma for sputtering the target material, yet low enough to allow those sputtered atoms to travel to the substrate with sufficient energy, ensuring a high-quality film.

The Two-Vacuum States of Sputtering

To understand sputtering pressure, you must think of it as a two-step process. Each step has a different goal and a vastly different pressure requirement.

Step 1: Achieving a Clean Slate (Base Pressure)

Before the sputtering process can begin, the vacuum chamber must be pumped down to a very low pressure, known as the base pressure.

This is typically in the high vacuum (HV) or ultra-high vacuum (UHV) range, often from 10⁻⁶ to 10⁻⁹ Torr.

The sole purpose of achieving a low base pressure is to remove contaminants. Molecules like oxygen, water vapor, and nitrogen will compromise the purity and integrity of your deposited film if they are not removed.

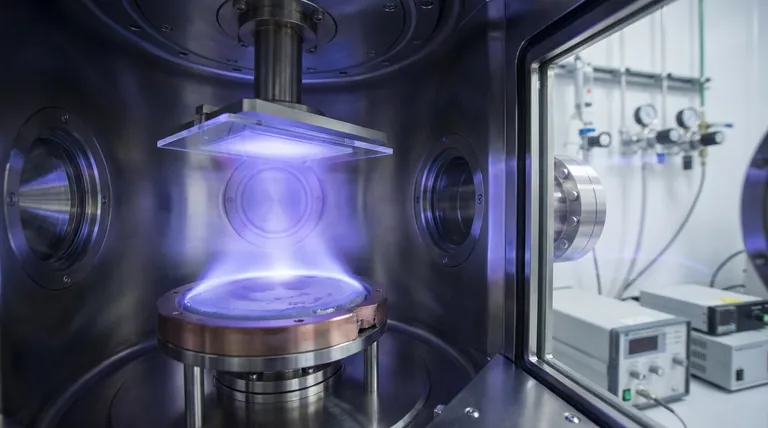

Step 2: Igniting the Process (Working Pressure)

Once a clean environment is established, a high-purity inert gas—almost always Argon (Ar)—is introduced into the chamber.

This deliberately raises the pressure to the working pressure, which is where the sputtering actually occurs. This is typically in the millitorr range, orders of magnitude higher than the base pressure.

The argon gas serves as the fuel for creating a plasma, a state of matter containing ionized gas atoms (Ar+) that are used to bombard the target material.

How Pressure Governs Film Quality

The working pressure is not just a number; it is arguably the most critical parameter that dictates the final properties of your deposited thin film.

Mean Free Path and Atom Energy

The key physical concept to understand is the mean free path (MFP). This is the average distance a particle (like a sputtered atom) can travel before it collides with another particle (like an argon gas atom).

At lower working pressures, the mean free path is long. Sputtered atoms travel from the target to the substrate with few or no collisions, arriving with high kinetic energy.

At higher working pressures, the mean free path is short. Sputtered atoms undergo many collisions with argon atoms, losing energy and changing direction before they reach the substrate.

The Impact on Film Structure

The energy of the atoms as they land on the substrate directly impacts the film's microstructure.

High-energy atoms (from low-pressure sputtering) have more mobility on the surface. They can arrange themselves into a dense, tightly-packed structure. This results in films with better adhesion, higher density, and lower electrical resistivity.

Low-energy atoms (from high-pressure sputtering) tend to "stick where they land." This creates a more porous, less-dense film structure, often with higher internal stress and poorer adhesion.

Understanding the Trade-offs

Choosing the correct working pressure is a balancing act. Deviating from the optimal range in either direction will degrade the process and the final result.

The Problem with Too Low Pressure

If the working pressure is too low, there are simply not enough argon atoms in the chamber.

This makes it difficult or impossible to ignite and sustain a stable plasma. The ion current will be too low to sputter the target effectively, leading to an extremely slow or non-existent deposition rate.

The Problem with Too High Pressure

This is a more common and subtle issue. If the pressure is too high, you create a dense "fog" of argon gas.

This leads to excessive gas scattering of the sputtered material. The atoms that eventually reach the substrate arrive with very little energy, resulting in the poor, porous film quality described earlier. The deposition rate can also decrease as atoms are scattered away from the substrate.

Making the Right Choice for Your Goal

The ideal pressure is determined by the desired properties of your thin film.

- If your primary focus is a high-density, high-purity film (e.g., for optics or electronics): You should operate at the lower end of the working pressure range (typically 1-5 mTorr) to maximize atom energy.

- If your primary focus is coating a complex, 3D shape: A slightly higher pressure might be beneficial, as the increased scattering can help "throw" material onto surfaces not in the direct line-of-sight of the target.

- If your primary focus is simply achieving a stable process with a reasonable rate: Start in the mid-range (e.g., 5-10 mTorr) and optimize based on film characterization.

Ultimately, mastering sputtering is about understanding and controlling the journey of individual atoms, and pressure is your primary tool for dictating that journey.

Summary Table:

| Sputtering Pressure Type | Typical Range | Purpose |

|---|---|---|

| Base Pressure | 10⁻⁶ to 10⁻⁹ Torr | Remove contaminants from the chamber before deposition. |

| Working Pressure | 1 to 100 mTorr | Sustain a plasma to sputter the target material onto the substrate. |

Ready to Optimize Your Sputtering Process?

Achieving the perfect balance between base and working pressure is critical for depositing high-quality, dense thin films. KINTEK specializes in providing the precise lab equipment and expert support you need to master your sputtering parameters.

We help you:

- Select the right vacuum components for your specific base pressure requirements.

- Achieve stable plasma conditions for consistent, high-purity deposition.

- Optimize your process for superior film adhesion, density, and electrical properties.

Contact us today to discuss how our sputtering solutions can enhance your research and production outcomes. Let's build the perfect system for your application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems