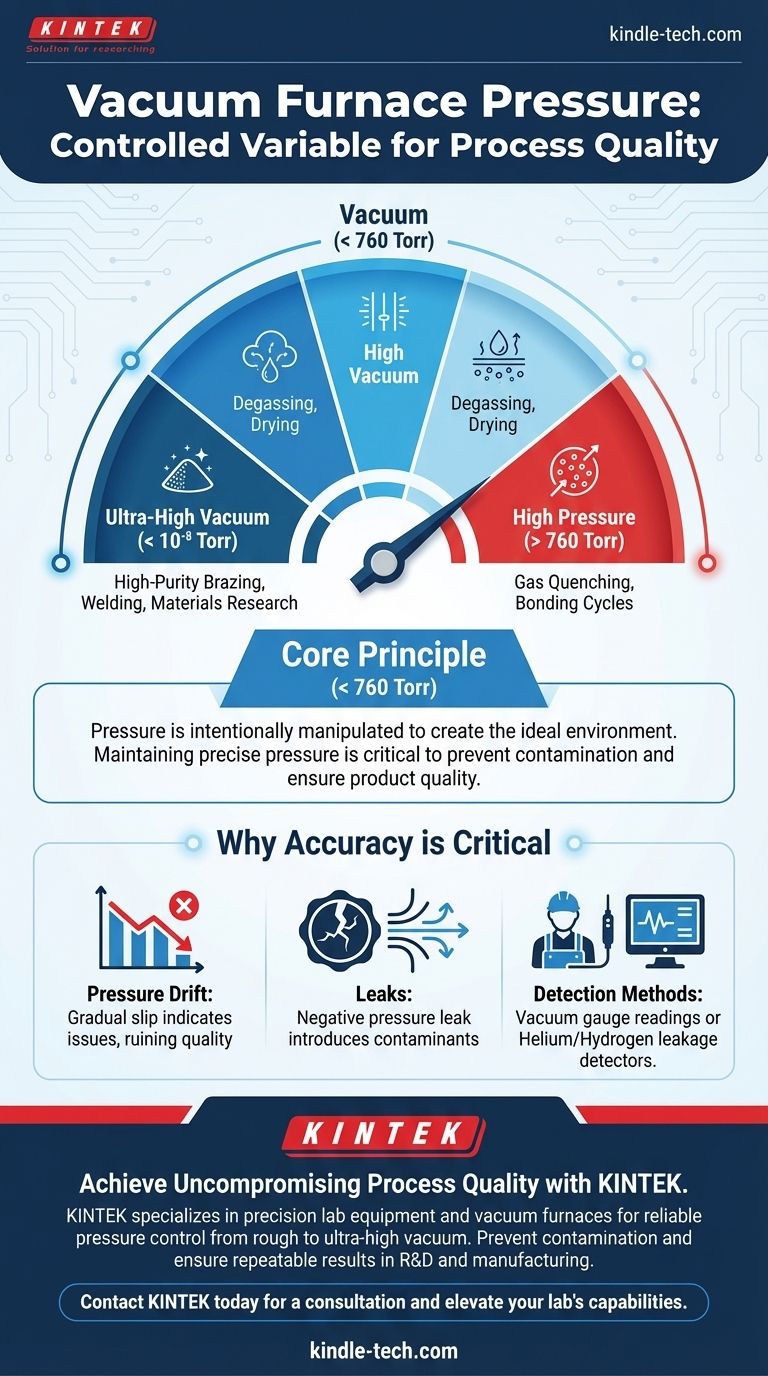

In a vacuum furnace, pressure is not a single value but a precisely controlled variable. The operational pressure can range from a rough vacuum just below atmospheric pressure (760 Torr) to an ultra-high vacuum with almost no air molecules (< 10⁻⁸ Torr). Some specialized furnaces can even operate at high pressures above atmospheric levels for specific process stages.

The core principle to understand is that the pressure inside a vacuum furnace is intentionally manipulated to create the ideal chemical environment for a specific high-temperature process. Maintaining this exact pressure is critical for preventing contamination and ensuring the quality of the final product.

Understanding Vacuum Pressure

Defining the Scale

In this context, pressure refers to the force exerted by the gas or air molecules remaining inside the furnace chamber. It's measured in a unit called Torr, where standard atmospheric pressure at sea level is approximately 760 Torr.

A "vacuum" simply means a pressure lower than 760 Torr. The "harder" the vacuum, the lower the Torr value and the fewer gas molecules are left in the chamber.

The Purpose of a Vacuum

The primary goal of creating a vacuum is to remove chemically reactive gases, especially oxygen. At the high temperatures used in these furnaces, many materials would rapidly oxidize or become contaminated if exposed to a normal atmosphere, compromising their structural integrity.

The Operational Ranges of a Vacuum Furnace

The required pressure level is dictated entirely by the sensitivity of the process being performed.

Rough Vacuum (< 760, > 1 Torr)

This is the least demanding level of vacuum. It's used for processes like degassing or drying, where the main goal is simply to remove bulk air and moisture without needing extreme purity.

High to Ultra-High Vacuum (< 10⁻⁸ Torr)

This range is reserved for the most sensitive applications. Processes like high-purity welding, brazing, or advanced materials research require an environment almost completely free of contaminants to achieve the desired metallurgical properties.

High Pressure (> 760 Torr)

Some advanced processes use a combination of vacuum and pressure. The furnace might first pull a deep vacuum to purify the environment and then backfill with a specific inert gas to a pressure above atmospheric level for a gas quenching or bonding cycle.

Common Pitfalls and Why Accuracy is Critical

The effectiveness of a vacuum furnace hinges on its ability to reach and hold a specific target pressure. Any deviation can lead to process failure.

The Impact of Pressure Drift

A gradual slip or inability to reach the target vacuum is a sign of a problem. As seen in sensitive applications like calibrating porcelain furnaces, even a minor deviation in vacuum pressure can ruin the quality of the final restoration.

The Problem of Leaks

The most common cause of pressure issues is a negative pressure leak, where atmospheric air is slowly drawn into the chamber through a faulty seal or crack. This introduces contaminants and prevents the pumps from maintaining the target vacuum.

Methods for Leak Detection

Leaks can be identified by observing unstable readings on the vacuum gauge tube. For precise detection, technicians can convert the negative pressure to a positive pressure by filling the chamber with a tracer gas and using a specialized helium or hydrogen leakage detector on the outside of the furnace.

Matching the Pressure to Your Goal

The right approach depends entirely on your operational objective.

- If your primary focus is basic degassing or material drying: A simple furnace capable of achieving a rough vacuum is sufficient and more cost-effective.

- If your primary focus is high-purity brazing or sensitive material processing: You require a high or ultra-high vacuum system with robust leak detection to prevent any contamination.

- If you are troubleshooting process failures: Your first step should always be to confirm the furnace's ability to hold its target vacuum using a calibrated gauge.

Ultimately, controlling the pressure inside a vacuum furnace is controlling the quality and outcome of your work.

Summary Table:

| Vacuum Level | Pressure Range (Torr) | Primary Applications |

|---|---|---|

| Rough Vacuum | < 760 to > 1 | Degassing, Drying |

| High/Ultra-High Vacuum | < 10⁻⁸ | High-Purity Brazing, Welding, Materials Research |

| High Pressure | > 760 | Gas Quenching, Specific Bonding Cycles |

Achieve Uncompromising Process Quality with KINTEK

Is inconsistent pressure compromising your high-temperature processes? KINTEK specializes in precision lab equipment, including vacuum furnaces designed for reliable pressure control from rough vacuum to ultra-high vacuum. Our solutions help laboratories in R&D and manufacturing prevent contamination and ensure repeatable, high-quality results.

Let our experts help you select the right vacuum furnace for your specific pressure and purity requirements.

Contact KINTEK today for a consultation and elevate your lab's capabilities.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Does platinum evaporate? Understanding High-Temperature Stability and Material Loss

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- Why is high-temperature vacuum heat treatment critical for Cr-Ni steel? Optimize Strength & Surface Integrity

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits