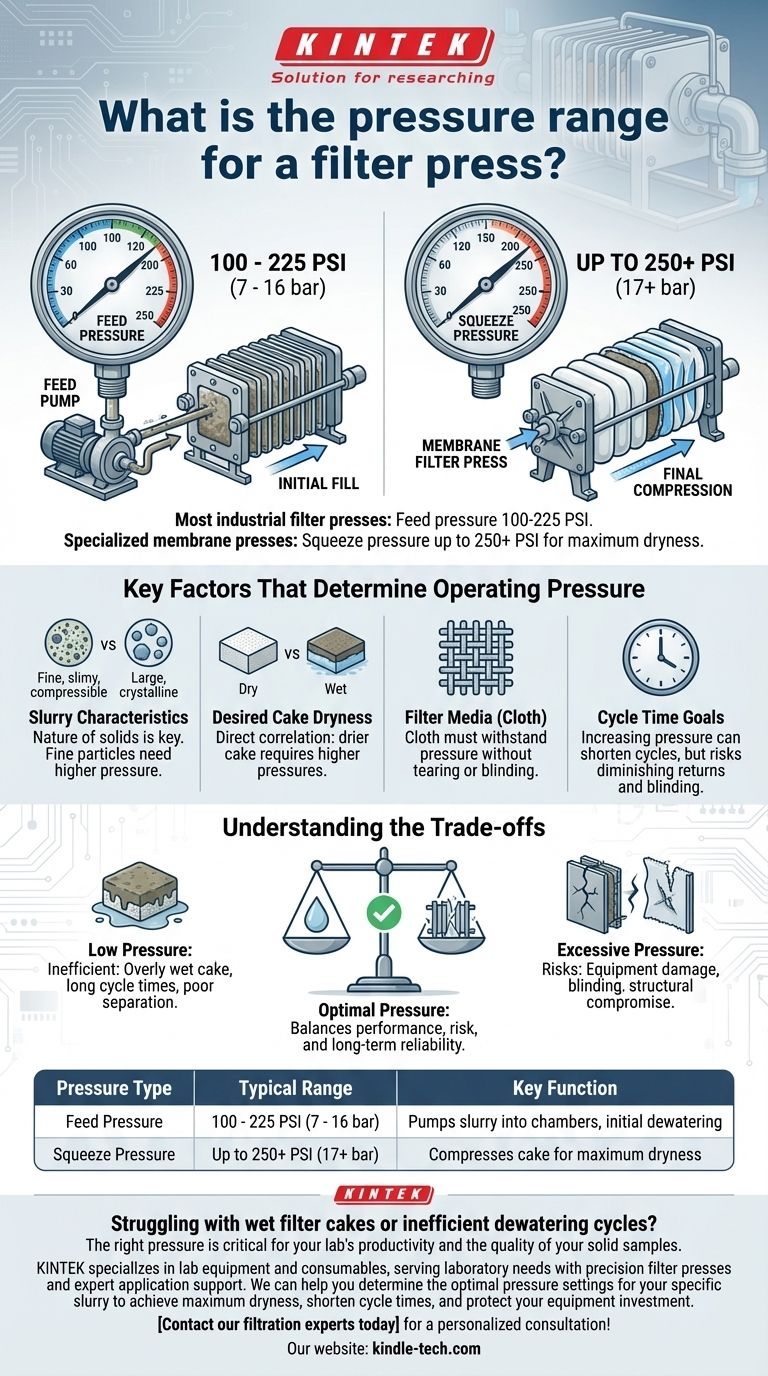

In short, most industrial filter presses operate with a feed pressure between 100 PSI (7 bar) and 225 PSI (16 bar). However, this number is only part of the story. Specialized membrane filter presses can also apply a "squeeze" pressure up to or exceeding 250 PSI (17 bar) to achieve maximum dryness.

The optimal pressure for a filter press is not a single value but a carefully controlled parameter. It depends entirely on your specific slurry, your desired cake dryness, and the design of the press itself. Applying the wrong pressure can lead to inefficiency at best and catastrophic equipment failure at worst.

The Two Sources of Pressure in a Filter Press

To understand the operating range, you must first distinguish between the two primary types of pressure applied during a filtration cycle.

Feed Pressure: The Initial Fill

This is the fundamental pressure in every filter press. It is generated by the feed pump, which pushes the slurry into the empty chambers between the filter plates.

This pressure overcomes the resistance of the filter cloth and the accumulating solid cake, forcing the liquid (filtrate) out. Standard systems typically operate at 100 PSI, while high-pressure systems are designed for 225 PSI.

Squeeze Pressure: The Final Compression

This second pressure stage is only available on membrane filter presses. After the chambers are filled and feed pressure is stopped, a flexible membrane on the plate surface is inflated with water or air.

This inflation "squeezes" the filter cake, physically forcing out additional liquid. Squeeze pressures typically range from 225 to 250 PSI and are essential for applications requiring the driest possible cake.

Key Factors That Determine Operating Pressure

The right pressure for your operation is not arbitrary; it is dictated by the physics of your process.

Slurry Characteristics

The nature of the solids being filtered is the single most important factor. Slurries with fine, slimy, or compressible particles create more resistance to flow and therefore require higher pressures to dewater effectively compared to slurries with large, crystalline particles.

Desired Cake Dryness

There is a direct correlation between pressure and final cake moisture. If your goal is to produce the driest possible solid cake for disposal or further processing, higher feed and squeeze pressures are necessary.

Filter Media (Cloth)

The filter cloth must be specified to handle the intended operating pressure without tearing. More importantly, the weave must be tight enough to capture the solids but permeable enough to allow water through without "blinding"—a condition where fine particles become permanently lodged in the cloth, blocking flow.

Cycle Time Goals

In some cases, increasing the pressure can shorten the filtration cycle time. However, this has a point of diminishing returns and can be counterproductive if it causes premature blinding of the filter cloths.

Understanding the Trade-offs: The Dangers of Incorrect Pressure

Simply running a filter press at its maximum rated pressure is often a mistake. Understanding the balance between performance and risk is critical for safe and efficient operation.

The Problem with Low Pressure

Operating at a pressure that is too low for your slurry is inefficient. It results in an overly wet and sloppy filter cake, long cycle times, and poor separation performance, defeating the purpose of the equipment.

The Risks of Excessive Pressure

High pressure is not always better. Exceeding the design limits or applying too much pressure too quickly can have severe consequences.

These risks include damaging the filter cloths, cracking the expensive filter plates, or even compromising the structural integrity of the press frame. It can also force fine particles so deep into the cloth that it blinds instantly, stopping the process entirely.

How to Determine the Right Pressure for Your Application

Selecting the correct pressure range is about matching the equipment's capability to your specific operational goal.

- If your primary focus is standard dewatering of municipal or industrial waste: A standard press rated for 100 PSI (7 bar) is often the most cost-effective and reliable choice.

- If your primary focus is achieving maximum cake dryness for valuable solids (e.g., mining concentrates) or to minimize disposal weight: A high-pressure press (225 PSI / 16 bar) or a membrane squeeze press (250+ PSI / 17+ bar) is necessary.

- If you are processing difficult, fine-particle slurries: Higher pressure may be required, but pilot-scale testing is essential to find the optimal pressure that maximizes dewatering without blinding the filter media.

Ultimately, the optimal pressure is not the maximum pressure, but the correct pressure that balances cake dryness, cycle time, and long-term equipment reliability.

Summary Table:

| Pressure Type | Typical Range | Key Function |

|---|---|---|

| Feed Pressure | 100 - 225 PSI (7 - 16 bar) | Pumps slurry into chambers, initial dewatering |

| Squeeze Pressure (Membrane Presses) | Up to 250+ PSI (17+ bar) | Compresses cake for maximum dryness |

Struggling with wet filter cakes or inefficient dewatering cycles? The right pressure is critical for your lab's productivity and the quality of your solid samples. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision filter presses and expert application support.

We can help you determine the optimal pressure settings for your specific slurry to achieve maximum dryness, shorten cycle times, and protect your equipment investment. Contact our filtration experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples