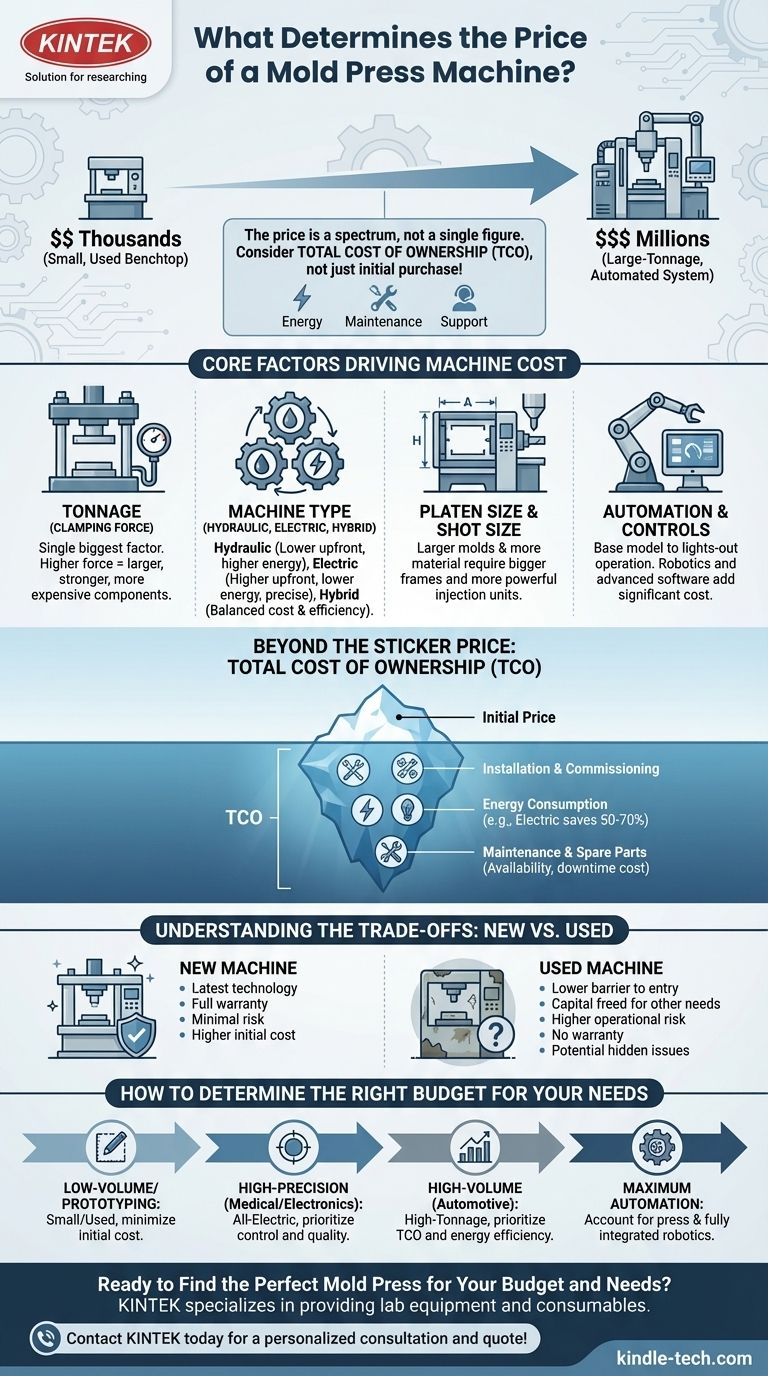

The price of a mold press machine is not a single figure but a vast spectrum, ranging from a few thousand dollars for a small, used benchtop unit to well over a million for a large-tonnage, highly automated system. The final cost is determined by a combination of force, size, technology, and features. Simply asking for "the price" is like asking for the price of a vehicle; the answer depends entirely on whether you need a simple scooter or an industrial haulage truck.

A molding press's price tag is a direct reflection of its specific capabilities. The most critical error is to focus only on the initial purchase price instead of the Total Cost of Ownership (TCO), which includes energy consumption, maintenance, and the support required to keep it running profitably.

The Core Factors Driving Machine Cost

The sticker price of any molding press is driven by a few fundamental engineering and manufacturing principles. Understanding these will allow you to decode why one machine costs significantly more than another.

Tonnage (Clamping Force)

Tonnage is the force the machine uses to hold the mold closed during the injection process. It is often the single biggest factor in determining the price.

A higher tonnage rating means the machine's frame, platens, and hydraulic or mechanical systems must be larger and stronger to withstand the immense pressure. This requires more raw material and more robust engineering, directly increasing the cost.

Machine Type: Hydraulic, Electric, or Hybrid

The technology used to power the machine's movements has a major impact on both initial cost and long-term operating expense.

- Hydraulic presses are the traditional workhorses. They generally have a lower upfront cost for higher tonnages but are less energy-efficient and can be less precise.

- All-electric presses use high-performance servo motors instead of hydraulics. They offer superior precision, repeatability, and energy efficiency but come with a higher initial purchase price.

- Hybrid presses combine a hydraulic system for high-force functions with electric motors for other movements, offering a balance between the cost of hydraulic and the efficiency of electric.

Platen Size and Shot Size

The platen size dictates the maximum physical dimensions of the mold that can be fitted into the machine. Larger platens require a larger, more expensive machine frame.

Shot size refers to the maximum volume of material the machine can inject into the mold at one time. A larger shot size requires a more powerful injection unit, adding to the overall cost.

Automation and Control Systems

A base-model press is only the starting point. The level of automation and the sophistication of the control system are significant cost drivers.

Features like integrated multi-axis robots for part removal, vision systems for quality control, or advanced process monitoring software can add tens or even hundreds of thousands of dollars to the final price.

Beyond the Sticker Price: The Total Cost of Ownership

A savvy investor looks beyond the initial purchase. The true cost of a machine reveals itself over its operational lifetime.

Installation and Commissioning

The price on the quote rarely includes the cost of rigging the machine into place, connecting utilities (power, water, air), and having a certified technician perform the initial setup and calibration. These costs can be substantial.

Energy Consumption

This is a critical TCO factor. An all-electric press may cost 20-30% more upfront but can reduce energy consumption by 50-70% compared to an older hydraulic machine, leading to massive savings over years of operation.

Maintenance and Spare Parts

Consider the availability and cost of spare parts and technical support. A machine from an established brand with a strong local presence may cost more initially but save you from costly downtime if a critical component fails.

Understanding the Trade-offs: New vs. Used

The decision to buy new or used equipment is a fundamental trade-off between capital expenditure and operational risk.

The Case for a New Machine

A new press comes with the latest technology for efficiency and control, a full manufacturer's warranty, and comprehensive support. The initial cost is higher, but the operational risk is minimal.

The Case for a Used Machine

A used machine offers a significantly lower barrier to entry, freeing up capital for other needs like tooling or materials. However, this comes with risks: no warranty, potential for hidden mechanical issues, and less efficient technology that leads to higher long-term energy costs.

How to Determine the Right Budget for Your Needs

To get an accurate price, you must first define your goal. A machine is a tool, and the right tool depends entirely on the job.

- If your primary focus is low-volume production or prototyping: A smaller, lower-tonnage press or a quality used machine is a sensible choice to minimize initial capital outlay.

- If your primary focus is high-precision manufacturing (e.g., medical or electronics): Prioritize an all-electric machine for its superior control and budget for its higher initial cost as a necessary investment in quality.

- If your primary focus is high-volume, large-part production (e.g., automotive): You will need a high-tonnage hydraulic or hybrid press, where TCO and energy efficiency are the most critical financial metrics.

- If your primary focus is maximizing automation: Your budget must account for the press and the fully integrated robotics and downstream equipment required for a "lights-out" operation.

Ultimately, the right investment is not the cheapest machine, but the one that most cost-effectively meets your specific production requirements.

Summary Table:

| Cost Factor | Impact on Price | Key Considerations |

|---|---|---|

| Tonnage (Clamping Force) | High | Higher tonnage requires stronger, more expensive components. |

| Machine Type (Hydraulic/Electric/Hybrid) | High | Electric presses cost more upfront but save on energy. |

| Platen & Shot Size | Medium | Larger sizes require a bigger, more expensive machine frame. |

| Automation & Controls | Variable | Adds $10,000s to $100,000s for robotics and advanced software. |

| New vs. Used | High | Used machines lower initial cost but increase operational risk. |

Ready to Find the Perfect Mold Press for Your Budget and Needs?

Determining the right machine is a complex decision that balances upfront cost with long-term performance and efficiency. KINTEK specializes in providing lab equipment and consumables, including solutions for your material processing and production needs.

Let our experts help you analyze your specific requirements—from tonnage and platen size to automation levels—and guide you toward the most cost-effective investment for your laboratory or production facility.

Contact KINTEL today for a personalized consultation and quote! We'll work with you to ensure you get the right press to maximize your ROI and production quality.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis