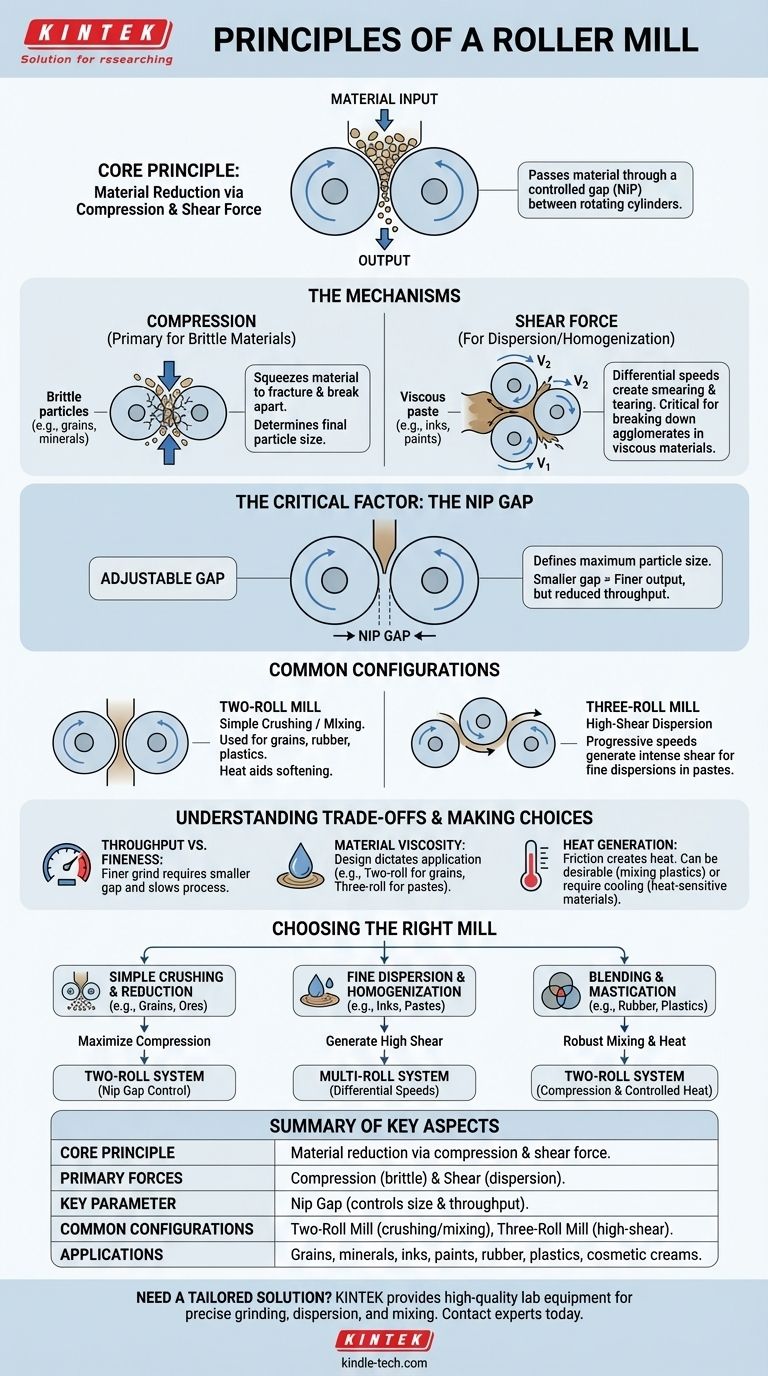

At its core, a roller mill operates on the principle of material reduction through a combination of compression and shear force. This is accomplished by passing material through a precisely controlled gap, known as the nip, between two or more rotating cylinders. The rollers draw the material in, subjecting it to intense pressure that crushes, grinds, or disperses it.

A roller mill is not a single device but a category of machines defined by a shared principle: using the controlled interaction between rotating rollers—their speed, gap, and configuration—to achieve a desired particle size, texture, or mixture consistency.

The Core Mechanism: Compression and Shear

The effectiveness of any roller mill comes from its ability to apply two distinct types of force. The balance between these forces is determined by the mill's design and the material being processed.

The Role of Compression

Compression is the primary force in simpler roller mills. As material is pulled into the narrowing gap between the rollers, it is squeezed until it fractures and breaks apart.

This action is most effective for brittle materials like grains or minerals, where the goal is straightforward size reduction. The final particle size is largely determined by the minimum gap between the rollers.

The Power of Shear Force

Shear force is generated when adjacent rollers rotate at different speeds. One surface moves faster than the other, creating a smearing and tearing action on the material trapped between them.

This force is critical for dispersing and homogenizing viscous materials like inks, paints, or cosmetic creams. The intense shear breaks down agglomerates and ensures a smooth, uniform mixture, a task that compression alone cannot accomplish.

The Critical Factor: The Nip Gap

The gap between the rollers is the most fundamental control parameter. It defines the maximum size of any particle that can pass through.

Adjusting this gap allows an operator to precisely control the fineness of the grind or the degree of dispersion. A smaller gap results in a finer output but typically reduces the processing speed (throughput).

Common Roller Mill Configurations

The term "roller mill" applies to several distinct designs, each optimized for different materials and outcomes. Understanding these configurations clarifies how the core principle is applied in practice.

The Two-Roll Mill

This is the most basic configuration, often used for simple crushing or mixing. Material is fed into the nip between two rollers, which may rotate at the same or slightly different speeds.

This design is common for processing bulk solids like grain or for masticating rubber and plastics, where the heat generated by the rollers helps soften the material.

The Three-Roll Mill

The three-roll mill is a more sophisticated design engineered for generating extremely high shear. It consists of three parallel rollers that rotate at progressively higher speeds.

Material is fed between the first (feed) and second (center) rolls. It is then transferred to the center roll and passed through the even smaller, faster-moving gap between the center and third (apron) rolls. This two-stage shearing process is ideal for creating extremely fine dispersions in high-viscosity pastes.

Understanding the Trade-offs

While powerful, roller mills are governed by a set of operational realities. Acknowledging these trade-offs is key to using them effectively.

Throughput vs. Fineness

There is a direct trade-off between how fast you can process material and how fine the output will be. Achieving a very fine grind requires a small nip gap and sometimes multiple passes, both of which slow down the overall process.

Material Viscosity is Key

The properties of the input material dictate the appropriate mill design. A simple two-roll mill is sufficient for dry, brittle grains but is entirely ineffective for dispersing a thick paste. Conversely, a three-roll mill is overkill and inefficient for basic crushing tasks.

Heat Generation

The friction and pressure within the mill generate significant heat. In some applications, like plastics processing, this is a desirable effect that aids in mixing. In others, such as grinding heat-sensitive chemicals or foods, it can be a major problem that requires the use of cooled rollers to prevent material degradation.

Making the Right Choice for Your Goal

Your application determines which aspect of the roller mill's principle is most important.

- If your primary focus is simple crushing and size reduction (e.g., grains, ores): You need a system that maximizes compression, where the key parameter is the control over the nip gap in a two-roll setup.

- If your primary focus is fine dispersion and homogenization (e.g., inks, pastes): You need a multi-roll system with differential speeds to generate the high shear forces necessary to break down agglomerates.

- If your primary focus is blending and mastication (e.g., rubber, plastics): You need a robust two-roll system that uses both compression and controlled heat generation to achieve the desired consistency.

By understanding the interplay of compression, shear, and roller configuration, you can effectively control the final properties of your processed material.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Material reduction via compression and shear force between rotating rollers. |

| Primary Forces | Compression (for brittle materials) and Shear (for dispersion/homogenization). |

| Key Parameter | Nip Gap (controls particle size and throughput). |

| Common Configurations | Two-Roll Mill (simple crushing/mixing), Three-Roll Mill (high-shear dispersion). |

| Applications | Grains, minerals, inks, paints, rubber, plastics, and cosmetic creams. |

Need a roller mill tailored to your specific material and output goals? KINTEK specializes in providing high-quality lab equipment, including roller mills for precise grinding, dispersion, and mixing. Whether you're processing grains, chemicals, or high-viscosity pastes, our solutions ensure optimal performance and consistency. Contact our experts today to discuss your application and find the perfect equipment for your laboratory needs!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What are the problems with ball mills? High Energy Use, Noise, and Component Wear Explained

- What is the role of a ball mill in preparing the suspension for EPD of spinel coatings? Ensure Density and Uniformity

- What are the drawbacks of a ball mill? Understanding Key Limitations for Your Process

- Why use zirconia grinding balls and jars for sulfide solid electrolytes? Essential Purity for Battery Innovation

- What is the name of the lab equipment used for grinding? Choose the Right Mill for Your Sample

- How does a probe-type ultrasonic homogenizer facilitate C3N4 exfoliation? Enhance Surface Area for Photocatalysis

- Where are hammer mills used? From Agriculture to Recycling, a Versatile Size-Reduction Solution

- Why use alternating cycles for carbide powder grinding? Key Benefits of Thermal Control in Milling