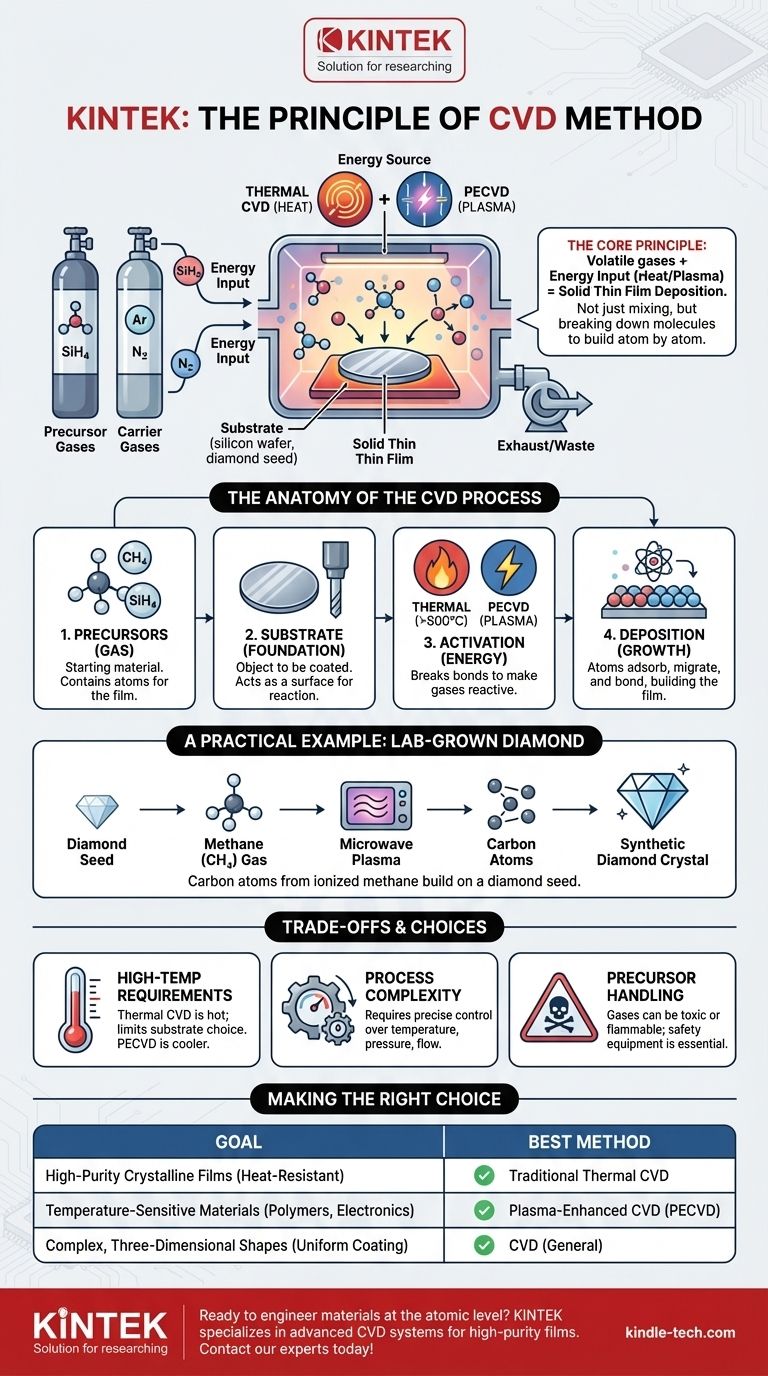

At its core, the principle of Chemical Vapor Deposition (CVD) is a material fabrication process where volatile precursor gases are introduced into a reaction chamber to produce a solid, thin film on a substrate. The key is an input of energy—typically heat or plasma—which causes the gases to react or decompose, depositing a new material layer onto the surface of the object you wish to coat.

The central concept of CVD is not merely mixing gases, but using a controlled energy source to break down specific gas molecules into their constituent atoms. These atoms then systematically build a new, solid layer on a target substrate, effectively constructing a material from the bottom up.

The Anatomy of the CVD Process

To truly understand the principle, we must break the process down into its fundamental stages. Each step is a control point that determines the final properties of the deposited film.

The Precursors: Starting with Gas

The process begins with one or more precursor gases. These are volatile compounds that contain the specific atoms needed for the final film.

For example, to deposit a silicon film, a gas like silane (SiH₄) might be used. These precursors are often mixed with inert carrier gases (like argon or nitrogen) to dilute them and control their transport to the substrate.

The Foundation: The Substrate

A substrate is the material or object that will be coated. This could be a silicon wafer for manufacturing microchips, a tool bit for a hard coating, or a small diamond seed for growing a larger synthetic diamond.

The substrate is placed inside the chamber and often acts as the catalyst for the deposition, providing a surface where the chemical reactions can efficiently occur.

The Activation: Supplying Energy for Reaction

Gases will not spontaneously form a solid film. They require an input of energy to break their chemical bonds and become reactive. The method used to supply this energy is a major differentiator between types of CVD.

The most common method is Thermal CVD, where the substrate is heated to very high temperatures (often >800°C). When the precursor gases touch the hot surface, the thermal energy forces them to react and deposit the film.

Another key method is Plasma-Enhanced CVD (PECVD). Here, an electric field (often radio frequency or RF) is used to ionize the gas into a plasma. This plasma contains highly reactive radicals that can form a film at much lower temperatures, making it suitable for heat-sensitive substrates.

The Result: Film Growth and Deposition

Once the precursor gases are activated, their atoms or molecules adsorb (stick) onto the substrate surface. They then migrate across the surface until they find a stable site to bond, forming a solid film.

This process builds the film one atomic layer at a time, resulting in a dense and highly adherent coating. Unreacted gas and chemical byproducts are then pumped out of the chamber as waste.

A Practical Example: Growing a Diamond

The synthesis of lab-grown diamonds is a perfect illustration of the CVD principle in action.

The Seed and the Gas

A thin slice of a diamond, known as a seed crystal, is placed in the chamber to act as the substrate. The chamber is then filled with a carbon-rich precursor gas, typically methane (CH₄).

Creating the Plasma

Energy, often from microwaves, is used to ionize the gas mixture. This breaks the methane molecules apart, releasing pure carbon atoms within the plasma.

Building the Crystal

These free carbon atoms are drawn to the diamond seed crystal. They land on its surface and bond to the existing crystal lattice, perfectly mimicking its structure. This process is repeated for days or weeks, slowly growing a larger, high-purity diamond atom by atom.

Understanding the Inherent Trade-offs

While powerful, CVD is a process governed by critical trade-offs that are essential to understand.

High-Temperature Requirements

Traditional Thermal CVD requires extremely high temperatures. This limits the types of substrates that can be used, as many materials would be damaged or destroyed by the heat. This is precisely why methods like PECVD were developed.

Process Complexity and Control

CVD is not a simple "spray-on" coating. Achieving a high-quality, uniform film requires precise control over numerous variables, including temperature, pressure, gas flow rates, and chamber chemistry. Any deviation can compromise the final material's properties.

Precursor Handling and Cost

The precursor gases used in CVD can be highly toxic, flammable, or corrosive, necessitating complex and expensive safety and handling equipment. The cost of these specialized gases can also be a significant factor.

Making the Right Choice for Your Goal

Understanding the core principle allows you to select the right approach based on your specific objective.

- If your primary focus is high-purity, crystalline films on a heat-resistant substrate: Traditional Thermal CVD is often the most effective and established method.

- If your primary focus is depositing films on temperature-sensitive materials like polymers or assembled electronics: Plasma-Enhanced CVD (PECVD) is the necessary choice, as it allows deposition at much lower temperatures.

- If your primary focus is to coat complex, three-dimensional shapes uniformly: CVD is an excellent choice because the gas precursors can envelop the entire part, which is superior to line-of-sight methods.

By mastering these principles, you move from simply coating a surface to actively engineering a material at the atomic level.

Summary Table:

| CVD Process Stage | Key Function | Example Components |

|---|---|---|

| Precursor Gases | Supply atoms for the film | Silane (SiH₄), Methane (CH₄) |

| Substrate | Surface for film growth | Silicon wafer, tool bit, diamond seed |

| Energy Activation | Breaks gas bonds for reaction | Heat (Thermal CVD), Plasma (PECVD) |

| Film Deposition | Atomic layer-by-layer growth | Dense, adherent coatings |

Ready to engineer materials at the atomic level? KINTEK specializes in advanced lab equipment, including CVD systems, to help you achieve high-purity thin films for microelectronics, tool coatings, and synthetic diamond growth. Our expertise ensures precise control over temperature, pressure, and gas flow for superior results. Contact our experts today to discuss how our solutions can meet your specific laboratory needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application