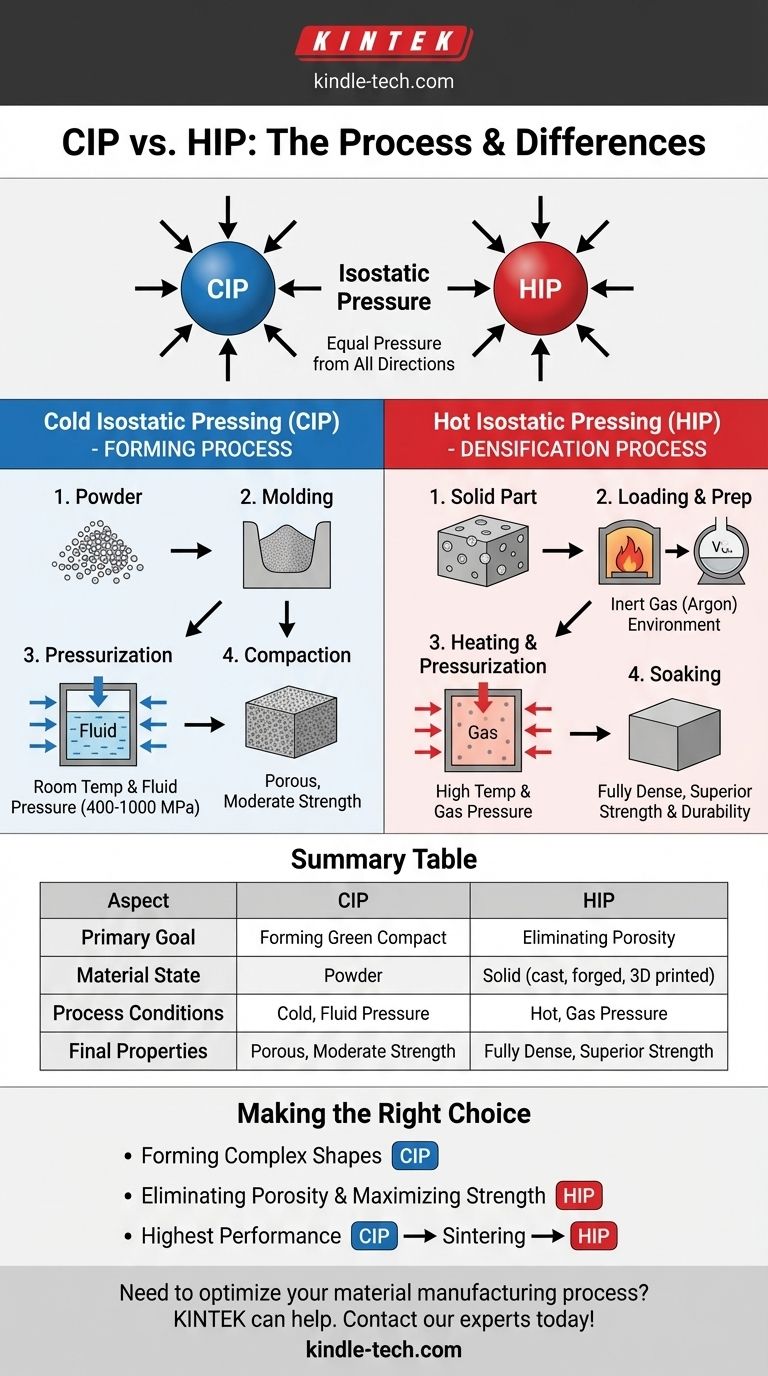

At its core, the primary difference is temperature. Cold Isostatic Pressing (CIP) uses extreme, uniform fluid pressure at room temperature to compact powders into a preliminary solid shape called a "green compact." In contrast, Hot Isostatic Pressing (HIP) uses both high temperature and high gas pressure to eliminate internal porosity and fully densify a part, dramatically improving its strength and durability.

The crucial distinction is their role in manufacturing. CIP is a forming process used to create an initial shape from powder, while HIP is a densification process used to perfect the final material properties of a component.

The Core Principle: Isostatic Pressure

What "Isostatic" Means

Both processes are built on the principle of isostatic pressure. This simply means applying pressure uniformly from all directions simultaneously.

Imagine an object submerged deep in the ocean. The water exerts equal pressure on every single point of its surface. This is the same principle used in CIP and HIP to ensure even compaction and densification without distorting the part's shape.

Breaking Down Cold Isostatic Pressing (CIP)

The Goal: Forming a "Green Compact"

The purpose of CIP is to take a loose powder and compact it into a solid, handleable object. This resulting part is known as a green compact—it has shape and some strength but is still porous and requires a subsequent heating process (sintering) to become a finished product.

The Step-by-Step Process

- Molding: A powdered material, often metal or ceramic, is placed inside a flexible, sealed mold made of rubber or urethane.

- Pressurization: This mold assembly is submerged in a fluid, typically water, inside a high-pressure chamber.

- Compaction: Extreme hydraulic pressure (from 400 to 1,000 MPa) is applied to the fluid, which in turn compresses the mold evenly from all sides, compacting the powder inside.

- Ejection: The pressure is released, and the now-solid green compact is removed from the mold, ready for the next manufacturing stage like sintering.

Breaking Down Hot Isostatic Pressing (HIP)

The Goal: Achieving Full Density

The purpose of HIP is to take an already solid part and eliminate any internal voids or porosity. This process heals internal defects in castings, strengthens 3D-printed metal parts, or fully densifies parts previously formed by CIP and sintering.

The Step-by-Step Process

- Loading: One or more components are loaded into a furnace, which is then sealed inside a high-pressure vessel.

- Preparation: Purging and vacuum cycles remove air, moisture, and other contaminants from the vessel to ensure a pure environment.

- Heating & Pressurization: The vessel is filled with a high-purity inert gas, usually Argon, and the temperature and pressure are raised simultaneously.

- Soaking: The part is held at a specific high temperature and pressure for an extended period, often 8 to 12 hours. The combination of heat (softening the material) and isostatic pressure collapses all internal pores.

- Cooling: The vessel is cooled, sometimes rapidly in a process that acts like quenching. The gas is released, often to be cleaned and recycled, and the fully densified parts are removed.

Understanding the Key Differences

Purpose: Forming vs. Densifying

This is the most critical distinction. CIP creates the shape. HIP perfects the material. A part might undergo CIP to be formed and then, after sintering, undergo HIP to achieve its maximum potential performance.

Material State: Powder vs. Solid

CIP almost exclusively starts with powder as its input material. HIP, on the other hand, is used on solid parts that may have been cast, forged, 3D printed, or created through powder metallurgy.

Process Conditions: Cold Fluid vs. Hot Gas

CIP is a cold process using a liquid medium (water) to transmit pressure. HIP is a high-temperature thermal process that uses an inert gas (Argon) to apply pressure.

Final Properties

CIP produces a green compact that is porous and has only moderate strength. It is an intermediate step. HIP produces a final component that is fully dense, free of internal defects, and possesses superior mechanical properties like strength and durability.

Making the Right Choice for Your Goal

- If your primary focus is creating a complex initial shape from powder: CIP is the correct forming step to produce a green compact before sintering.

- If your primary focus is eliminating porosity and maximizing the strength of a critical component: HIP is the essential final or near-final densification step.

- If your primary focus is achieving the highest possible performance from a powdered material: You will often use both processes sequentially—CIP to form, followed by sintering and then HIP to achieve full density.

Ultimately, choosing the right process depends entirely on what stage of the manufacturing journey your material is on.

Summary Table:

| Aspect | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Primary Goal | Forming a "green compact" from powder | Eliminating porosity in solid parts |

| Material State | Powder | Solid (cast, forged, 3D printed) |

| Process Conditions | Room temperature, fluid pressure (400-1000 MPa) | High temperature, inert gas pressure (Argon) |

| Final Properties | Porous, moderate strength (requires sintering) | Fully dense, superior strength and durability |

Need to optimize your material manufacturing process? Whether you're forming complex shapes from powder with CIP or achieving maximum density and strength with HIP, KINTEK's expertise in lab equipment and consumables can help you select the right technology for your laboratory's specific needs. Contact our experts today to discuss how our solutions can enhance your material performance and production efficiency!

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is isostatic pressing in powder metallurgy? Unlock Superior Part Density and Complexity

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- Purpose of CIP in c-LLZO ceramic pellets? Achieve >90% Density & Superior Uniformity with Cold Isostatic Pressing