At its core, the evaporation process in Physical Vapor Deposition (PVD) is a straightforward phase change. A source material is heated within a high-vacuum chamber until its atoms transform into a vapor. These vaporized atoms then travel through the vacuum and condense onto a cooler target object, known as a substrate, forming a solid, thin film.

Evaporation is fundamentally a two-step process driven by thermodynamics: a material is heated to create a vapor, and this vapor then naturally condenses back into a solid on any cooler surface it encounters. The high-vacuum environment is the critical enabler, ensuring the vapor travels unimpeded from the source to the substrate.

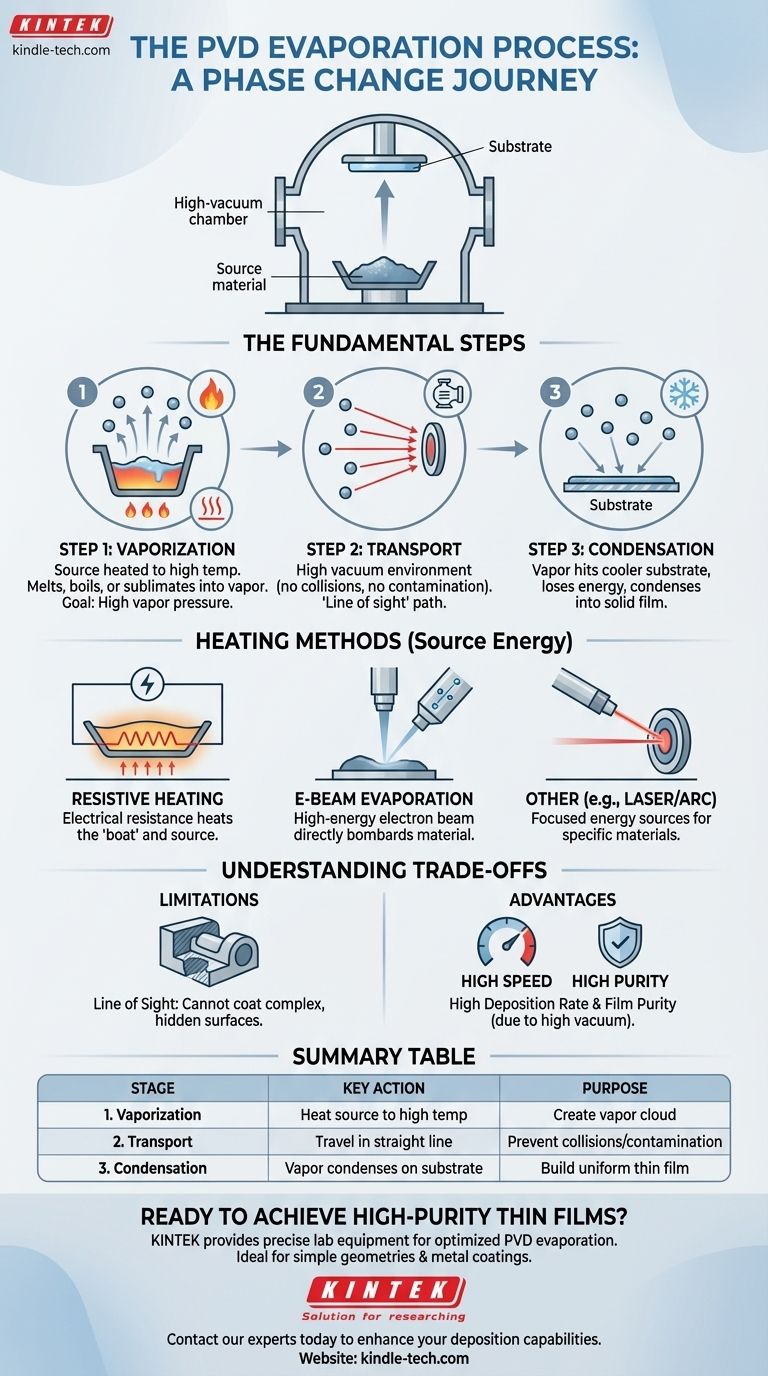

The Fundamental Steps of PVD Evaporation

The entire process, while technologically sophisticated, can be broken down into three distinct physical stages. Understanding each stage is key to understanding the capabilities and limitations of the method.

Step 1: Material Vaporization

The process begins by heating the source material, often called the "target," to an extremely high temperature.

Depending on the material and the pressure, it will either melt and then boil into a gaseous state or sublimate—transitioning directly from a solid to a vapor.

The goal is to generate a high vapor pressure, creating a dense cloud of atoms ready for transport.

Step 2: Vapor Transport

This stage is where the vacuum becomes essential. The chamber is pumped down to a very high vacuum to remove almost all air and other gas molecules.

This accomplishes two things: it prevents the vaporized atoms from colliding with other particles, and it eliminates unwanted chemical reactions with atmospheric gases like oxygen.

With no obstacles, the vaporized atoms travel in a straight path away from the source, a characteristic known as "line of sight" transport.

Step 3: Film Condensation

The vaporized atoms eventually reach the substrate, which is kept at a significantly lower temperature than the source.

Upon contact with this cooler surface, the atoms rapidly lose their thermal energy and condense back into a solid state.

This condensation builds up atom by atom, creating a highly uniform and thin film across the substrate's surface. Proper substrate heating can be used to improve film adhesion and structure.

Key Methods for Heating the Source Material

The primary difference between various evaporation techniques lies in how the initial energy is supplied to the source material to induce vaporization.

Resistive Heating (Thermal Evaporation)

This is one of the most common methods. The source material is placed in a container, often called a "boat" or filament, made of a refractory metal.

A high electrical current is passed through this boat, causing it to heat up due to electrical resistance. This heat is then transferred to the source material, causing it to evaporate.

Electron Beam (E-beam) Evaporation

For materials with very high melting points, a more intense energy source is required.

In E-beam evaporation, a high-energy beam of electrons is generated and magnetically guided to strike the source material. This direct electron bombardment instantly heats a localized spot to temperatures high enough for vaporization.

Other Methods

While less common, other energy sources can be used. Lasers can provide focused energy to heat the source material, and electric arcs can create a high-temperature plasma that vaporizes the target.

Understanding the Trade-offs

Evaporation is a powerful technique, but its characteristics create specific advantages and disadvantages that determine its suitability for a given application.

The "Line of Sight" Limitation

Because the vapor travels in a straight line, any part of the substrate not directly in the line of sight of the source will not be coated.

This makes evaporation challenging for coating complex, three-dimensional shapes with undercuts or hidden surfaces.

High Deposition Rate

A significant advantage of evaporation is its speed. Compared to other PVD techniques like sputtering, evaporation can deposit films much more quickly.

This makes it an excellent choice for applications requiring high throughput and rapid production cycles.

Film Purity

The high-vacuum environment is crucial for creating exceptionally pure films. By removing residual gases, the process minimizes the risk of the coating material reacting with contaminants or trapping gas pockets, which could compromise the film's integrity.

Making the Right Choice for Your Goal

Selecting the correct PVD method depends entirely on the material, the geometry of the part being coated, and the desired outcome.

- If your primary focus is speed and high throughput: Evaporation is often the preferred method due to its faster deposition rates compared to sputtering.

- If you are coating simple, flat, or gently curved surfaces: The "line of sight" nature of evaporation is perfectly suited for these geometries and ensures excellent uniformity.

- If your primary focus is creating high-purity films of metals: Evaporation in a high vacuum excels at producing clean, uncontaminated coatings of materials like aluminum, gold, and silver.

Ultimately, PVD evaporation is a direct and efficient method for turning a solid material into a high-performance thin film coating.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Vaporization | Heat source material to high temperature | Create a vapor cloud of atoms/molecules |

| 2. Transport | Atoms travel in a straight line through a high vacuum | Prevent collisions and contamination |

| 3. Condensation | Vapor condenses on a cooler substrate | Build a uniform, solid thin film |

Ready to achieve high-purity, high-throughput thin films in your lab?

PVD evaporation is ideal for coating simple geometries with metals like aluminum, gold, and silver. KINTEK specializes in providing the precise lab equipment and consumables you need to perfect your evaporation process.

Contact our experts today to discuss how our solutions can enhance your deposition capabilities and meet your specific laboratory requirements.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What is the process of thermal evaporation in PVD? A Step-by-Step Guide to Thin Film Deposition

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating