At its core, the purpose of a fluidized bed is to make a large mass of solid particles behave like a fluid. By pumping a gas or liquid upwards through a granular material, the solid particles become suspended and begin to mix and flow, which dramatically enhances the transfer of heat and mass between the particles and the fluid.

The fundamental challenge in many industrial processes is achieving intimate, uniform contact between a solid and a fluid. A fluidized bed solves this by transforming a static, inefficient solid bed into a dynamic, well-mixed system that behaves like a boiling liquid, unlocking superior process control and efficiency.

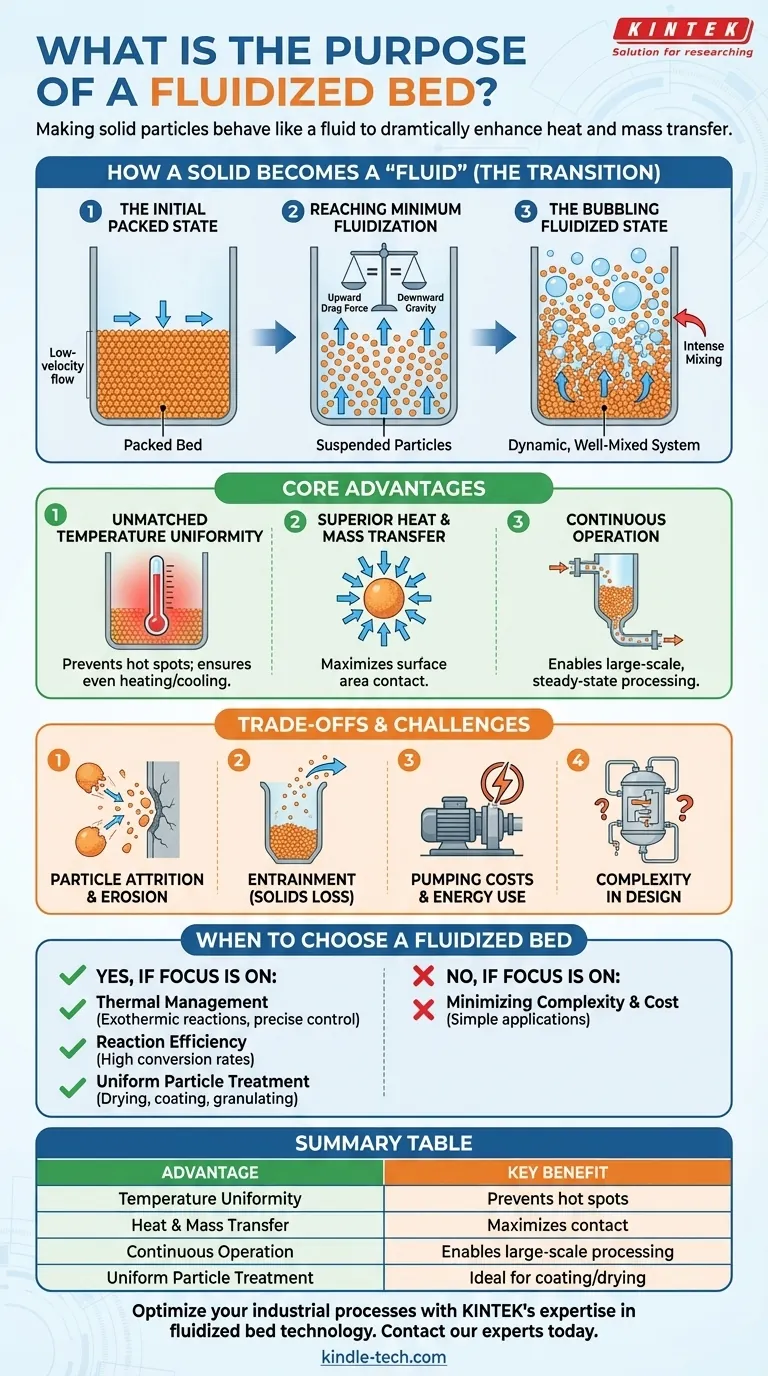

How a Solid Becomes a "Fluid"

To understand the purpose of a fluidized bed, you must first visualize the physical transformation that occurs. It is a transition from a static, packed state to a dynamic, suspended one.

The Initial Packed State

Imagine a container filled with a fine granular material, like sand. In this initial state, it is a packed bed. If you pass a fluid (like air) through it at a very low velocity, the air will simply find its way through the tortuous paths between the stationary particles.

Reaching Minimum Fluidization

As you gradually increase the velocity of the upward-flowing fluid, the drag force on each particle increases. At a specific velocity, known as the minimum fluidization velocity, this upward drag force perfectly balances the downward force of gravity on the particles.

At this critical point, the entire bed of solids expands slightly, and the particles are now suspended by the fluid, no longer resting on each other.

The Bubbling Fluidized State

If you increase the fluid velocity beyond the minimum, the excess fluid begins to coalesce and travel through the suspended solids as "bubbles." These bubbles rise and stir the particles vigorously, creating intense mixing.

The result is a system that looks and behaves remarkably like a boiling liquid. The solids flow, can be stirred, and maintain a level surface. This is the fluidized state, and it is this behavior that engineers seek to exploit.

The Core Advantages of Fluidization

Achieving this liquid-like state is not just a novelty; it provides powerful and distinct advantages over other methods of handling solids, such as packed beds or mechanical mixers.

Unmatched Temperature Uniformity

The rapid and continuous mixing of particles ensures that the temperature throughout the bed is remarkably uniform. This is critical for preventing hot spots in exothermic chemical reactions or ensuring even heating in drying processes.

This thermal uniformity allows for precise temperature control that is difficult or impossible to achieve in a static packed bed, where significant temperature gradients can form.

Superior Heat and Mass Transfer

In a fluidized bed, each individual particle is constantly surrounded by the fluid. This maximizes the surface area available for heat to move from the fluid to the particle (or vice-versa) and for chemical species to move between the fluid and the particle surface (mass transfer).

This efficiency far surpasses that of a packed bed, where the fluid may "channel" through preferred paths, bypassing large sections of the solid particles.

Continuous Operation and Solids Handling

Because the fluidized solids behave like a liquid, they can be continuously removed and added to the reactor system using pipes and valves. This is a massive advantage for large-scale, continuous industrial processes like oil refining or power generation.

Understanding the Trade-offs and Challenges

While powerful, fluidization is not a universal solution. The technology comes with specific operational complexities and trade-offs that must be managed.

Particle Attrition and Reactor Erosion

The constant, vigorous motion causes particles to collide with each other and the reactor walls. This can lead to particle attrition, where particles break down into smaller fines, and erosion of the reactor vessel itself.

Entrainment and Solids Loss

The upward-flowing fluid can carry smaller or lighter particles out of the top of the bed, a phenomenon known as entrainment. This requires downstream separation equipment, like cyclones, to capture these lost solids and return them to the bed.

Pumping Costs and Energy Use

Suspending an entire bed of heavy solids requires a significant and continuous flow of fluid, which translates directly into high energy consumption for pumps or blowers. These operational costs can be substantial.

Complexity in Design and Scale-up

The hydrodynamics of a fluidized bed are complex and can be difficult to predict. Scaling a design from a small laboratory unit to a large industrial reactor is not always straightforward and presents significant engineering challenges.

When to Choose a Fluidized Bed

The decision to use a fluidized bed depends entirely on whether its unique advantages outweigh its inherent complexities for your specific application.

- If your primary focus is thermal management: Use a fluidized bed for highly exothermic or endothermic reactions where preventing hot spots and maintaining precise temperature control is critical to safety and product quality.

- If your primary focus is reaction efficiency: Employ this technology for solid-catalyzed gas-phase reactions where maximizing the contact between reactants and the catalyst surface area is the key to high conversion rates.

- If your primary focus is uniform particle treatment: It is the ideal choice for large-scale drying, coating, or granulating of particulate solids, ensuring every particle receives consistent treatment.

- If your primary focus is minimizing complexity and cost: Consider a simpler fixed-bed or mechanical system for applications that are not sensitive to temperature gradients or do not require the high transfer rates that fluidization provides.

Ultimately, a fluidized bed is a powerful tool for overcoming the inherent physical limitations of interacting with solid materials on an industrial scale.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Temperature Uniformity | Prevents hot spots, ensures even heating/cooling |

| Heat & Mass Transfer | Maximizes surface area contact between solid and fluid |

| Continuous Operation | Enables large-scale, steady-state processing with easy solids handling |

| Uniform Particle Treatment | Ideal for drying, coating, or granulating applications |

Optimize your industrial processes with KINTEK's expertise in fluidized bed technology. Whether you're scaling up a chemical reaction, improving drying efficiency, or need precise thermal control, our lab equipment and consumables are designed to meet rigorous industrial demands. Contact our experts today to discuss how our solutions can enhance your productivity and product quality.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- How does the lab autoclave work? Achieve Complete Sterilization with High-Pressure Steam