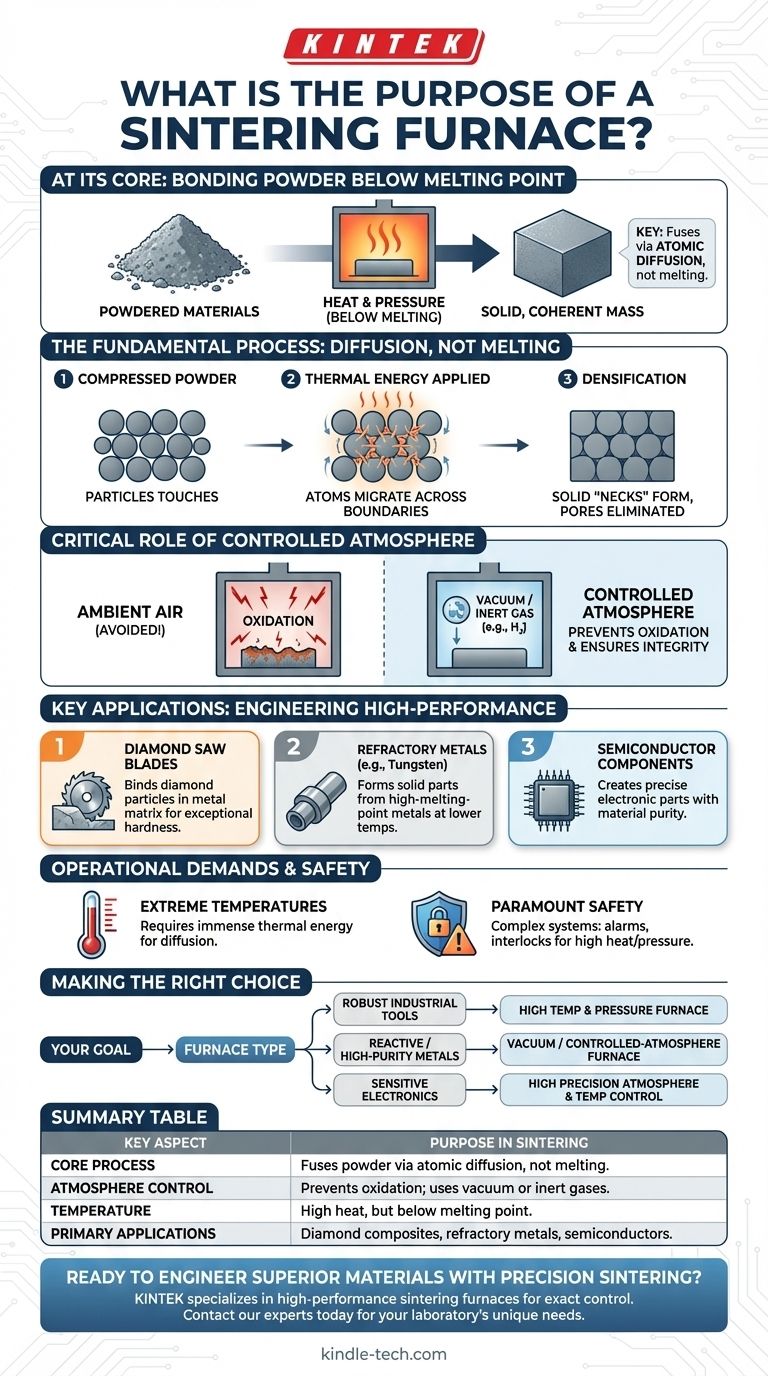

At its core, a sintering furnace is a specialized high-temperature oven designed to bond powdered materials into a solid, coherent mass. It achieves this using heat and often pressure, but crucially, it operates below the material's melting point, causing particles to fuse together through atomic diffusion. This process is essential for creating high-performance components from materials like diamond composites, refractory metals, and semiconductors.

The fundamental purpose of a sintering furnace is not to melt materials, but to provide a precisely controlled environment—in terms of temperature, pressure, and atmosphere—to transform loose powder into a dense, solid object with specific, engineered properties.

The Fundamental Process: Beyond Simple Melting

Understanding sintering requires moving past the idea of simple casting or melting. The process is far more nuanced and is used when melting is impractical or would destroy the material's desired properties.

How Sintering Works

Sintering applies thermal energy to a compressed powder. This heat energizes the atoms at the contact points between individual particles.

Instead of melting, the atoms migrate, or diffuse, across the boundaries of the particles. This diffusion creates solid "necks" or bridges between them, gradually eliminating the pores and increasing the density and strength of the final part.

The Critical Role of a Controlled Atmosphere

Many advanced materials are highly reactive with oxygen, especially at high temperatures. Sintering in ambient air would lead to oxidation, destroying the material's integrity.

A sintering furnace provides a controlled atmosphere to prevent this. A vacuum sintering furnace, for example, removes air entirely. Others use protective gases like hydrogen to create an inert or reducing environment, which is essential for sintering refractory alloys like tungsten and molybdenum.

Key Applications

The applications of sintering highlight its unique capabilities. It is used to create:

- Diamond Saw Blades: Sintering is used to bind industrial diamond particles within a metallic matrix, creating an exceptionally hard and durable cutting tool.

- Refractory Metals: Metals like tungsten have extremely high melting points, making them difficult to cast. Sintering allows them to be formed into solid parts at lower temperatures.

- Semiconductor Components: The process is used to create precise electronic parts and power rectifiers where material purity and structural integrity are paramount.

Understanding the Trade-offs and Demands

While powerful, the sintering process and the furnaces that enable it come with significant operational demands that dictate their design and use.

The Necessity of Extreme Temperatures

The diffusion process at the heart of sintering requires immense thermal energy. Furnaces must be capable of reaching and maintaining extraordinarily high temperatures for long periods to ensure the complete and uniform bonding of the material.

The Central Importance of Safety

Due to the extreme conditions—high temperatures, high amperage, and sometimes high pressure—safety is the most important design feature.

These furnaces are not simple ovens. They incorporate complex safety systems, including over-temperature and over-pressure alarms, mechanical pressure protection, and interlocking mechanisms that prevent unsafe operation. These features are essential for protecting both the equipment and the personnel operating it.

Making the Right Choice for Your Goal

The type of sintering furnace required is dictated entirely by the material being processed and the desired outcome.

- If your primary focus is producing robust industrial tools: A furnace capable of high temperatures and pressures is needed to effectively bind composite materials like metal-diamond matrixes.

- If your primary focus is working with reactive or high-purity metals: A vacuum or controlled-atmosphere furnace is non-negotiable to prevent oxidation and ensure material integrity.

- If your primary focus is manufacturing sensitive electronics: You need a furnace offering the highest degree of precision in both atmospheric and temperature control to produce reliable components.

Ultimately, choosing the right sintering furnace is a critical step in engineering materials with properties that would otherwise be impossible to achieve.

Summary Table:

| Key Aspect | Purpose in Sintering |

|---|---|

| Core Process | Fuses powder particles via atomic diffusion, not melting. |

| Atmosphere Control | Prevents oxidation; uses vacuum or inert gases like hydrogen. |

| Temperature | Operates at high heat, but crucially below the material's melting point. |

| Primary Applications | Manufacturing diamond composites, refractory metals, and semiconductors. |

Ready to engineer superior materials with precision sintering? KINTEK specializes in high-performance lab equipment, including sintering furnaces designed for exact temperature and atmosphere control. Whether you're developing durable industrial tools or high-purity semiconductor components, our expertise ensures your process achieves maximum density and material integrity. Contact our experts today to find the perfect sintering solution for your laboratory's unique needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al

- What conditions does a vacuum hot press provide for Al2O3/ZrO2 sintering? Achieve 1550°C and 30 MPa Densification

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution