In short, cryogenic grinding is a pulverizing process that uses extreme cold, typically from liquid nitrogen, to make materials brittle. This allows for the efficient grinding of materials that are too soft, flexible, or heat-sensitive to be processed effectively at room temperature.

The fundamental purpose of cryogenic grinding is not just to reduce particle size, but to do so while perfectly preserving the material's original chemical and physical properties by eliminating the destructive forces of heat and friction.

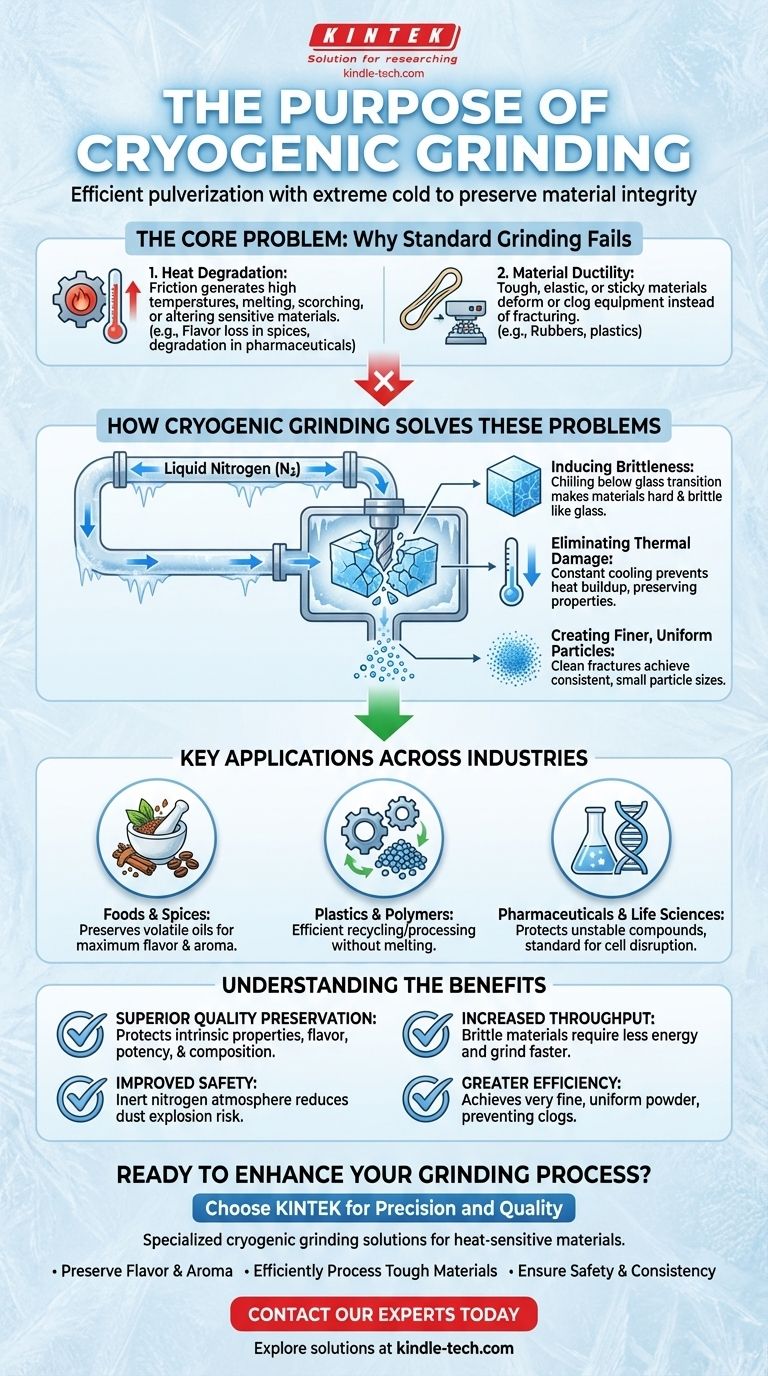

The Core Problem: Why Standard Grinding Fails

Traditional grinding relies on mechanical force, which generates significant friction and heat. For many materials, this is a destructive process that compromises the final product.

Heat Degradation

The friction from standard grinding can raise temperatures high enough to melt, scorch, or chemically alter a substance.

This is especially problematic for materials with volatile components, such as the essential oils in spices, which would evaporate and lose their flavor and aroma.

Material Ductility and Softness

Many materials, like rubbers and certain plastics, are naturally tough, elastic, or sticky at ambient temperatures.

When subjected to standard grinding, these materials don't fracture into a fine powder. Instead, they deform, melt, or clog the grinding equipment, making the process inefficient or impossible.

How Cryogenic Grinding Solves These Problems

By fundamentally changing the material's physical state, cryogenic grinding overcomes the limitations of heat and ductility.

Inducing Brittleness

The process chills a material below its glass transition temperature, a point where it loses its ductile and rubbery properties.

This super-cooling makes the material extremely hard and brittle, similar to glass. In this state, it shatters easily and cleanly upon impact, creating a fine, uniform powder.

Eliminating Thermal Damage

The cryogenic fluid, most often liquid nitrogen, acts as a constant and powerful coolant throughout the entire grinding process.

This prevents any heat buildup from friction, thereby protecting heat-sensitive compounds, preserving biochemical properties in biological samples, and stopping polymers from melting.

Creating Finer, More Uniform Particles

Because the material fractures cleanly in its brittle state, cryogenic grinding can achieve a much finer and more consistent particle size than is possible with many soft materials at ambient temperatures.

Key Applications Across Industries

The unique advantages of this process make it essential in several fields where material integrity is paramount.

Foods and Spices

Cryogenic grinding is used to pulverize spices, herbs, and coffee. It preserves the full profile of volatile oils, ensuring maximum flavor, aroma, and quality in the final powder.

Plastics and Polymers

The process is critical for recycling or processing thermoplastics, thermosets, and rubbers. It allows these tough materials to be efficiently reduced to powder without melting or degradation, which is crucial for manufacturing pigments, coatings, and additives.

Pharmaceuticals and Life Sciences

In pharmaceuticals, it is used for unstable compounds that would be destroyed by heat. In molecular biology, it's a standard method for cell disruption, breaking open frozen cells to extract proteins and other components for analysis without damaging their structure.

Understanding the Benefits

Choosing cryogenic grinding is a strategic decision to prioritize quality and efficiency, especially with challenging materials.

Benefit: Superior Quality Preservation

The primary advantage is the protection of the material's intrinsic properties. This results in products with better flavor, higher potency, and unchanged chemical composition.

Benefit: Increased Throughput

Brittle materials require less energy and time to grind. This leads to faster processing, reduced power consumption, and increased overall efficiency of the operation.

Benefit: Improved Safety

Using an inert gas like nitrogen displaces oxygen from the grinding chamber. This significantly reduces the risk of dust explosions when processing flammable or volatile materials.

Making the Right Choice for Your Goal

Cryogenic grinding is a specialized solution for specific material challenges.

- If your primary focus is preserving quality and volatile compounds: This is the ideal method for high-value spices, pharmaceuticals, and sensitive biological samples.

- If your primary focus is processing difficult materials: This is the most effective way to pulverize tough, elastic, or sticky polymers, plastics, and rubbers.

- If your primary focus is achieving a very fine, uniform powder: This process offers superior control over particle size, especially for materials that would otherwise clog equipment.

Ultimately, cryogenic grinding is the definitive technique when the integrity of the material being ground is as important as the particle size you wish to achieve.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Preserves Quality | Protects volatile compounds, flavors, and chemical properties from heat damage. |

| Handles Tough Materials | Makes elastic or sticky materials brittle for efficient grinding. |

| Improves Safety | Inert nitrogen atmosphere reduces risk of dust explosions. |

| Increases Efficiency | Brittle materials grind faster, using less energy and increasing throughput. |

Ready to Enhance Your Grinding Process with Precision and Quality?

If you work with heat-sensitive materials like spices, polymers, or pharmaceuticals, achieving a fine powder without degradation is critical. KINTEK specializes in advanced laboratory equipment, including cryogenic grinding solutions, designed to meet the exacting needs of modern labs.

Our expertise ensures you can:

- Preserve the full flavor profile of food products.

- Process tough plastics and rubbers efficiently.

- Safely handle volatile or flammable materials.

- Achieve a consistent, fine particle size for superior product quality.

Let KINTEK provide the reliable equipment and support you need to optimize your operations. Contact our experts today to discuss your specific application and discover the perfect solution for your lab!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis