In short, the purpose of pyrolysis products is to transform low-value materials like biomass and waste into valuable outputs. These outputs fall into three categories: a liquid fuel known as bio-oil, a solid carbon-rich material called bio-char, and a combustible gas mixture called syngas. Each of these has distinct applications in energy, agriculture, and chemical production.

Pyrolysis is best understood not as waste disposal, but as a material conversion process. It unlocks the stored value in a feedstock by breaking it down into a versatile portfolio of solid, liquid, and gaseous products, each serving a different economic or environmental purpose.

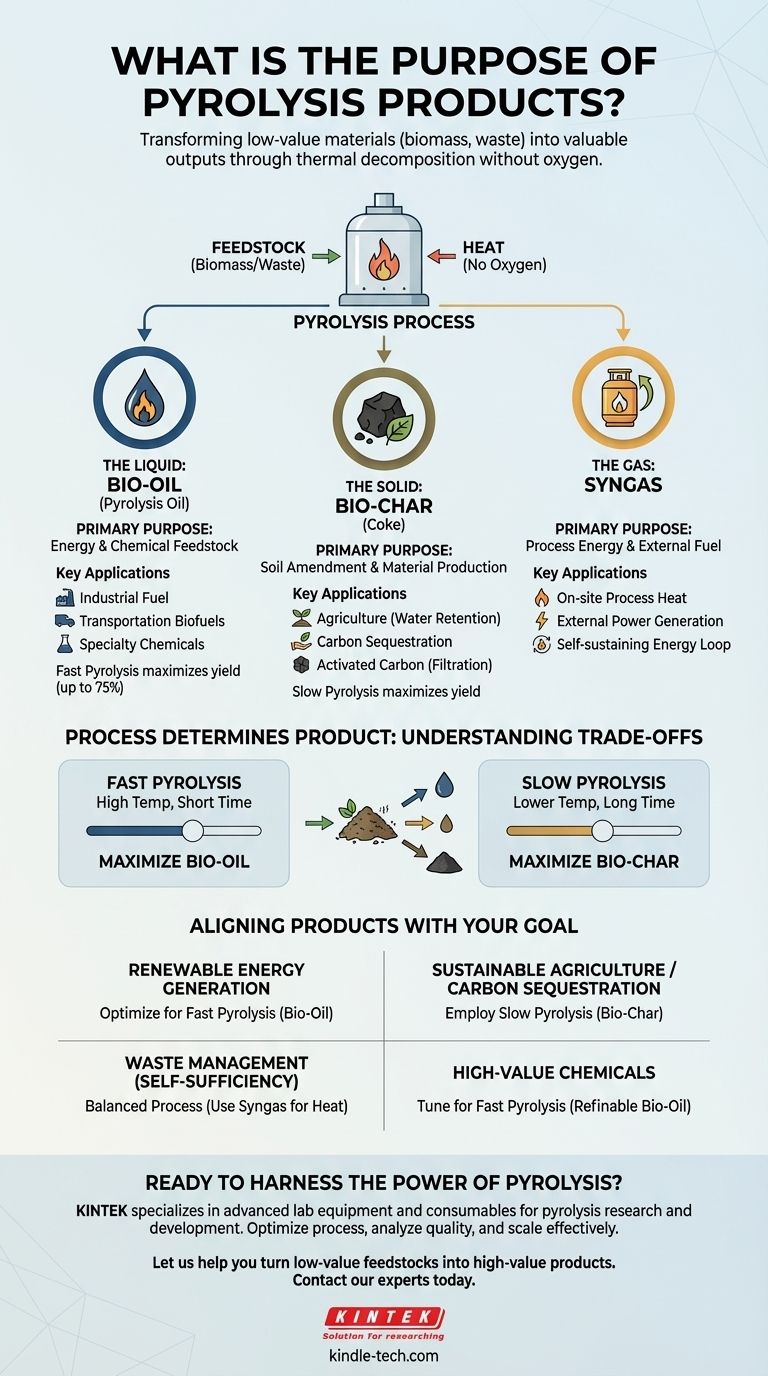

Deconstructing the Outputs: The Three Core Products

Pyrolysis is a process of thermal decomposition in the absence of oxygen. Rather than burning a material, it breaks it down into its fundamental components. The specific yield and composition of these components depend heavily on the feedstock and process conditions.

The Liquid: Bio-Oil

Bio-oil (or pyrolysis oil) is a dark, dense liquid often seen as the primary target of many pyrolysis operations, particularly "fast pyrolysis" which maximizes its yield. It is a complex mixture of oxygenated organic compounds.

Its primary purpose is as a source of energy and chemicals. It can be used directly as a substitute for industrial fuel oil in boilers and furnaces for heat and power generation. With further refining, it can be upgraded into transportation fuels like biodiesel or serve as a feedstock for producing specialty chemicals and plastics.

The Solid: Bio-char

Bio-char (or coke) is the stable, carbon-rich solid that remains after the volatile components have been driven off. The conditions of "slow pyrolysis" are often tuned to maximize the production of this solid.

Its main purpose lies in agriculture and material science. As a soil amendment, it improves water retention, reduces nutrient runoff, and can sequester carbon in the soil for long periods. It also serves as a raw material for producing activated carbon, a powerful sorbent used in water and air filtration.

The Gas: Syngas

Syngas is the mix of non-condensable gases produced during the process, primarily composed of hydrogen, carbon monoxide, and methane. While it can be collected and used for external energy generation, its most common purpose is internal.

Most modern pyrolysis plants use the syngas they produce as fuel to generate the heat required for the pyrolysis reaction itself. This creates a self-sustaining energy loop, significantly reducing the plant's operational costs and external energy dependence.

Understanding the Trade-offs: Process Determines Product

It is critical to understand that you cannot maximize the output of all three products simultaneously. The specific goal of a pyrolysis operation dictates the method used, creating a fundamental trade-off.

Fast vs. Slow Pyrolysis

Fast pyrolysis, which involves heating the feedstock very quickly to a moderate temperature and then rapidly cooling the vapors, is designed to maximize the yield of bio-oil, often achieving up to 75% liquid product by weight. This is the preferred route for energy and fuel production.

Slow pyrolysis, which uses lower temperatures over a much longer period, is designed to maximize the yield of bio-char. This method is ideal for applications focused on agriculture, soil remediation, and carbon sequestration.

Feedstock Matters

The nature of the input material also dictates the output. Woody biomass will produce different product ratios and qualities compared to plastic waste or agricultural residue. The design and purpose of a pyrolysis facility must be aligned with the specific feedstock it is intended to process.

Aligning Products with Your Primary Goal

The "best" use of pyrolysis products is entirely dependent on your strategic objective. There is no single answer, only the right approach for a specific goal.

- If your primary focus is renewable energy generation: Optimize your process for fast pyrolysis to maximize bio-oil yield for use in boilers or for upgrading to transportation fuels.

- If your primary focus is sustainable agriculture or carbon sequestration: Employ slow pyrolysis to produce high-quality bio-char for use as a long-term soil amendment.

- If your primary focus is waste management with maximum self-sufficiency: A balanced process where the syngas produced is used to power the operation is the most efficient model.

- If your primary focus is creating high-value chemicals: Your system must be tuned for fast pyrolysis to yield a refinable bio-oil, with significant investment in downstream processing.

Ultimately, pyrolysis provides a powerful and flexible toolkit for converting low-value streams into a range of valuable and marketable commodities.

Summary Table:

| Product | Primary Purpose | Key Applications |

|---|---|---|

| Bio-Oil (Liquid) | Energy & Chemical Feedstock | Industrial fuel, transportation biofuels, specialty chemicals |

| Bio-Char (Solid) | Soil Amendment & Material Production | Agriculture, carbon sequestration, activated carbon for filtration |

| Syngas (Gas) | Process Energy & External Fuel | On-site heat for pyrolysis, external power generation |

Ready to harness the power of pyrolysis for your operation?

Whether your primary goal is renewable energy generation, sustainable agriculture, or efficient waste management, selecting the right equipment is critical to maximizing your yield of bio-oil, bio-char, or syngas.

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. We provide the tools you need to optimize your process conditions, analyze product quality, and scale your technology effectively.

Let us help you turn low-value feedstocks into high-value products. Contact our experts today to discuss how our solutions can support your specific pyrolysis goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds