In essence, the significance of compression molding lies in its unique ability to produce very large, high-strength, and complex composite parts with exceptional consistency. It is a cornerstone manufacturing process for applications demanding structural integrity over sheer production speed, creating components that are both dimensionally stable and have an excellent finish on all sides.

Compression molding is the definitive process when your primary requirements are structural strength and dimensional stability, particularly for large-format parts made from thermoset or composite materials. It trades the rapid cycle times of other methods for superior part integrity.

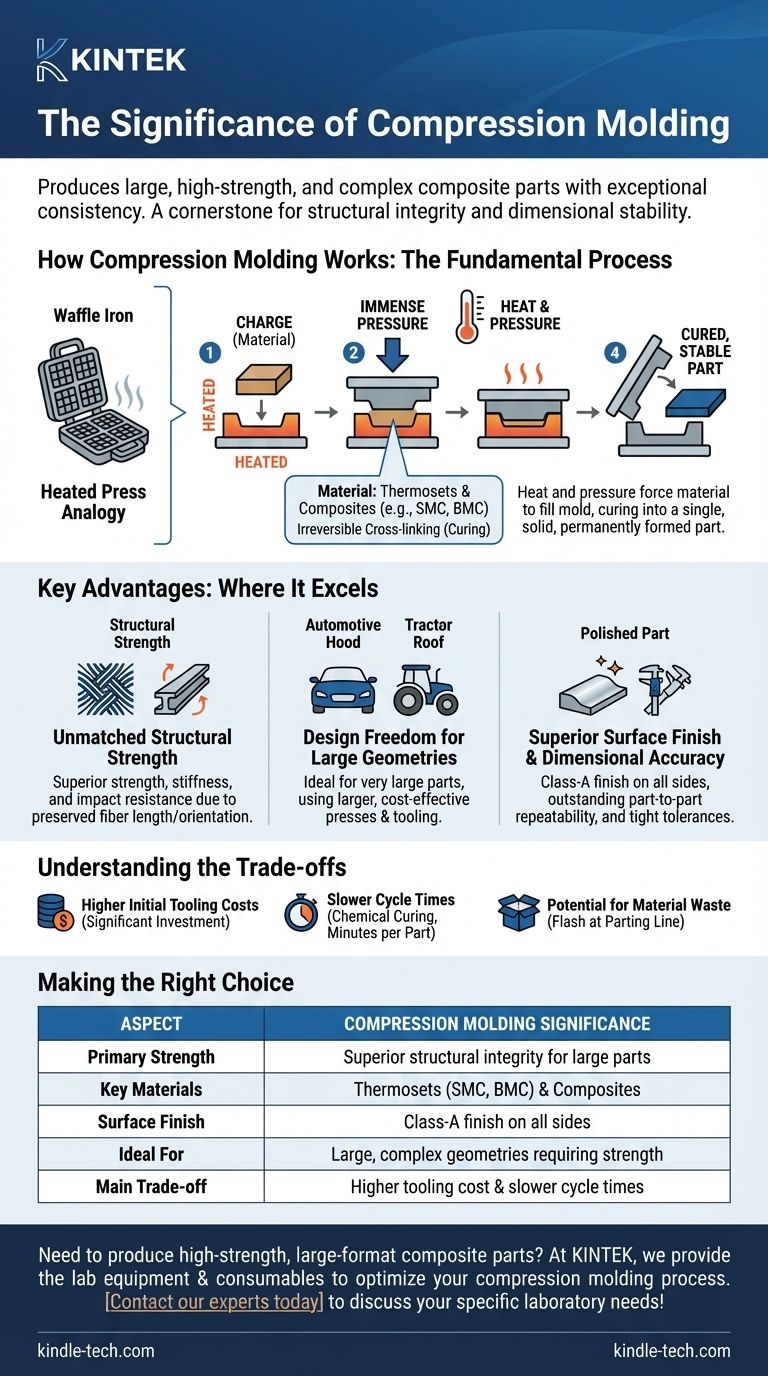

How Compression Molding Works: The Fundamental Process

To appreciate its significance, you must first understand the process. It is mechanically simple but chemically sophisticated.

The "Heated Press" Analogy

At its core, compression molding is like a high-tech waffle iron. A pre-measured amount of molding material, called the charge, is placed into the open, heated lower half of a mold cavity.

The top half of the mold then closes, applying immense pressure. The combination of heat and pressure forces the material to fill every crevice of the mold.

The Critical Role of Material

This process is most commonly used for thermosetting plastics and composite materials like Sheet Molding Compound (SMC) or Bulk Molding Compound (BMC).

Unlike thermoplastics that can be melted and reformed, thermosets undergo an irreversible chemical reaction called cross-linking when heated. This is the key to the final part's strength and stability.

The Result: A Cured, Stable Part

The heat and pressure are maintained until the curing reaction is complete. The result is a single, solid, permanently formed part that is then ejected from the mold.

Key Advantages: Where Compression Molding Excels

The method's significance is defined by several key advantages that other processes, like injection molding, cannot easily replicate.

Unmatched Structural Strength

Because the material charge is placed into the mold rather than injected under high velocity, the reinforcing fibers within a composite (like long glass or carbon fibers) maintain their length and orientation. This results in parts with superior strength, stiffness, and impact resistance.

Design Freedom for Large Geometries

The process is uniquely suited for producing very large parts, such as automotive body panels, hoods, tractor roofs, and large electrical enclosures. The lower pressures compared to injection molding allow for larger, more cost-effective presses and tooling.

Superior Surface Finish and Dimensional Accuracy

The use of matched metal molds means that both the "A" and "B" sides of the part are formed against a hard, polished tool surface. This creates two Class-A finished surfaces and ensures outstanding part-to-part repeatability and tight dimensional tolerances.

Understanding the Trade-offs and Limitations

No process is perfect. To make an informed decision, you must weigh the benefits against the inherent trade-offs.

Higher Initial Tooling Costs

The robust, matched-metal molds required for compression molding are a significant capital investment. This makes the process less suitable for very low-volume production or prototyping.

Slower Cycle Times

The curing process is chemical, not just thermal, and it takes time—typically from one to several minutes per part. This is considerably slower than the seconds-long cycle times common in thermoplastic injection molding.

Potential for Material Waste

Excess material, known as flash, is often squeezed out at the mold's parting line. While this can be trimmed, it represents material waste that must be factored into the overall part cost.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your project's primary goal.

- If your primary focus is maximum strength and rigidity in a large component: Compression molding is the superior choice, especially when using long-fiber reinforced composites.

- If your primary focus is mass production of small, complex thermoplastic parts: Injection molding will deliver far faster cycle times and lower per-part costs once tooling is paid for.

- If your primary focus is prototyping or producing complex, one-off parts: 3D printing (additive manufacturing) or CNC machining offer unparalleled flexibility without the high cost of tooling.

Ultimately, understanding the unique strengths and limitations of compression molding empowers you to align your manufacturing method with your specific engineering and business goals.

Summary Table:

| Aspect | Significance of Compression Molding |

|---|---|

| Primary Strength | Superior structural integrity for large parts |

| Key Materials | Thermosets (SMC, BMC) & composites |

| Surface Finish | Class-A finish on all sides |

| Ideal For | Large, complex geometries requiring strength |

| Main Trade-off | Higher tooling cost & slower cycle times |

Need to produce high-strength, large-format composite parts?

At KINTEK, we specialize in providing the lab equipment and consumables necessary for developing and testing materials for compression molding. Whether you're working with Sheet Molding Compound (SMC), Bulk Molding Compound (BMC), or other thermoset composites, our solutions help ensure your materials meet the demanding requirements for strength, dimensional stability, and surface finish.

Let us help you optimize your process for superior results. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- Small Injection Molding Machine for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is mold in design? The Key to Mass-Producing Your Physical Product

- Why are high-strength graphite molds necessary for Cu/Ti3SiC2/C/MWCNTs composites? Ensure Precision at 950°C

- What is the use of potassium bromide in IR? Achieve Clear Solid Sample Analysis with KBr Pellets

- What are the applications of moulding process? Powering Mass Production from Cars to Medical Devices

- What role do specialized graphite dies play in vacuum hot pressing? Enhance Al2O3/Cu-Cr Composite Precision

- What is Mould filling analysis? Predict Injection Molding Defects Before Cutting the Mold

- What function does a graphite mold serve during the hot-press sintering of fluoride ceramics? Enhance Densification

- What are the functions of high-purity graphite molds in SiC Hot Pressing and SPS? Optimize Your Sintering Precision