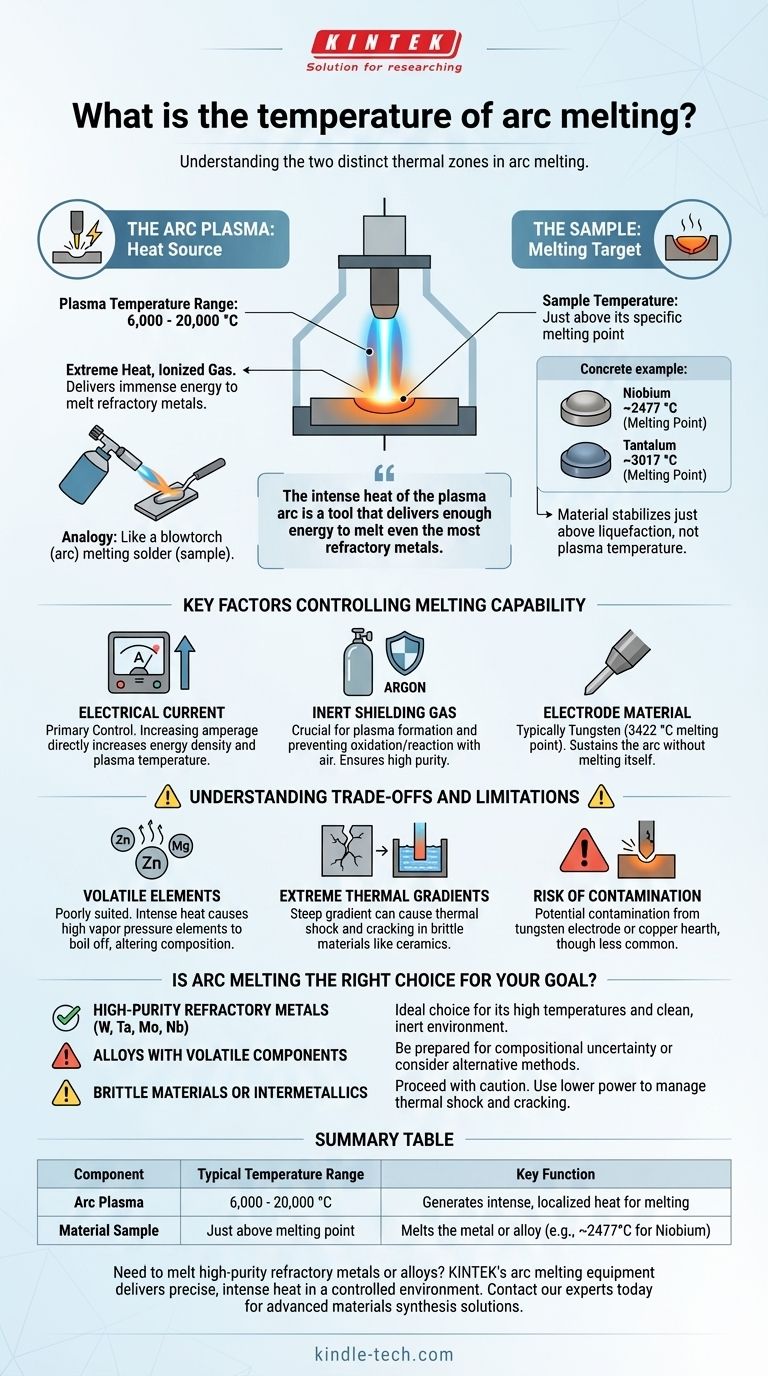

In arc melting, there is no single temperature. Instead, the process involves two distinct thermal zones: the electric arc plasma itself and the material being melted. The plasma arc can reach extreme temperatures, often between 6,000 and 20,000 °C (approximately 11,000 to 36,000 °F), while the material sample is heated just above its specific melting point.

The critical insight is not the temperature of the arc, but its capability. The intense heat жерт the plasma arc is a tool that delivers enough energy to melt even the most refractory metals, like tungsten, which melts at 3422 °C (6192 °F).

The Two Temperatures of Arc Melting

To understand the process, it's essential to differentiate between the heat source and the object being heated. Think of it like using a blowtorch to melt solder; the flame is far hotter than the solder's melting point.

The Arc Plasma: The Heat Source

An electric arc is a channel of plasma—an ionized gas. In an arc melter, this is typically created by passing a high current through an inert gas like argon.

This plasma is exceptionally hot. Temperatures in the core of the arc can readily exceed 6,000 °C and, depending on the current and gas pressure, can reach as high as 20,000 °C. This is the source of the immense energy used for melting.

The Sample: The Melting Target

The purpose of this extreme plasma temperature is to transfer enough energy to the sample material (often called a "button") to raise its temperature above its melting point.

The sample itself will not reach 20,000 °C. Instead, its temperature will stabilizeFactional just above its liquefaction point. For example, if you are melting niobium, the button will be slightly above its melting point of 2477 °C. If melting tantalum, it will be just over 3017 °C.

Key Factors Controlling the Melting Capability

The ability市场 to melt a specific material is controlled by调 the energy delivered by the arc, which is influenced by several factors.

Electrical Current

This is the primary control. Increasing the amperage passed through the electrode directly increases the energy density and temperature of the plasma arc, allowing for the melting of higher-melting-point materials or larger samples.

Inert Shielding Gas

Arc melting is performed in a controlled atmosphere, almost always using a high-purity inert gas like argon.

The gas serves two purposes: it forms the plasma needed for the arc and, crucially, it prevents the molten metal from oxidizing or reacting with air, ensuring high purity.

Electrode Material

The non-consumable electrode is typically made of tungsten, chosen for its extremely high melting point (3422 °C). This allows the electrode to sustain the arc without melting itself and contaminating the sample.

Understanding the Trade-offs and Limitations

While powerful, arc melting is not universally applicable. Its unique characteristics present specific challenges.

Difficulty with Volatile Elements

The process is poorly suited for alloys containing elements with high vapor pressures (i.e., low boiling points), such as zinc, magnesium, or manganese. The intense, localized heat can cause these elements to boil off, leading to significant changes in the final alloy composition.

Extreme Thermal Gradients

The heat from the arc is incredibly concentrated. This creates a steep thermal gradient between the molten pool and the cool, water-chilled copper hearth below it. For brittle materials like certain intermetallics or ceramics, this thermal shock can cause cracking.

Risk of Contamination

Although it is a very clean melting technique, there is a small risk of contamination. If the arc becomes unstable or the current is too high, it can damage the tungsten electrode tip, introducing tungsten into the melt. Contamination from the copper hearth is also a possibility, though less common.

Is Arc Melting the Right Choice for Your Goal?

Use this guide to determine if arc melting suits your specific materials synthesis objective.

- If your primary focus is high-purity refractory metals and alloys (W, Ta, Mo, Nb): Arc melting is the industry-standard technique and your ideal choice due to its high temperatures and clean, inert environment.

- If your primary focus is alloys with volatile components (e.g., high-manganese steels): You must be prepared for compositional uncertainty due to element boiling, or consider alternative methods like induction melting in a pressurized chamber.

- If your primary focus is brittle materials or intermetallics: Proceed with caution, using lower power and careful technique to manage the risk of thermal shock and cracking during solidification.

Ultimately, arc melting provides a powerful, localized heat source capable of exceeding the melting point of any known metal, making it a critical tool for advanced materials synthesis.

Summary Table:

| Component | Typical Temperature Range | Key Function |

|---|---|---|

| Arc Plasma (Heat Source) | 6,000 - 20,000 °C | Generates intense, localized heat for melting |

| Material Sample (Target) | Just above its specific melting point | Melts the metal or alloy (e.g., ~2477°C for Niobium) |

Need to melt high-purity refractory metals or alloys? KINTEK's arc melting equipment delivers the precise, intense heat required for materials like tungsten, tantalum, and molybdenum in a controlled, inert environment. Our solutions are designed for researchers and labs focused on advanced materials synthesis. Contact our experts today to discuss how our lab equipment can meet your specific melting challenges!

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- Why is specialized heating equipment necessary for TiC-steel debinding? Ensure Purity Before Sintering

- What is the temperature of the arc melting furnace? Achieve 3000°C for Refractory Metals

- Which factors are critical in heat treatment? Master Temperature, Atmosphere & Cooling for Superior Results

- What materials are used in vacuum chambers? Choose the Right Material for Your Vacuum Level

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity

- What is the effect of high-temperature vacuum on passivation films? Master Refractory Alloy Stability

- What role does a precision laboratory oven play in the hydrothermal synthesis of copper sulfate nanocrystals?

- What is the function of the condensation cover in a vertical single-stage vacuum furnace? Expert Purification Insights