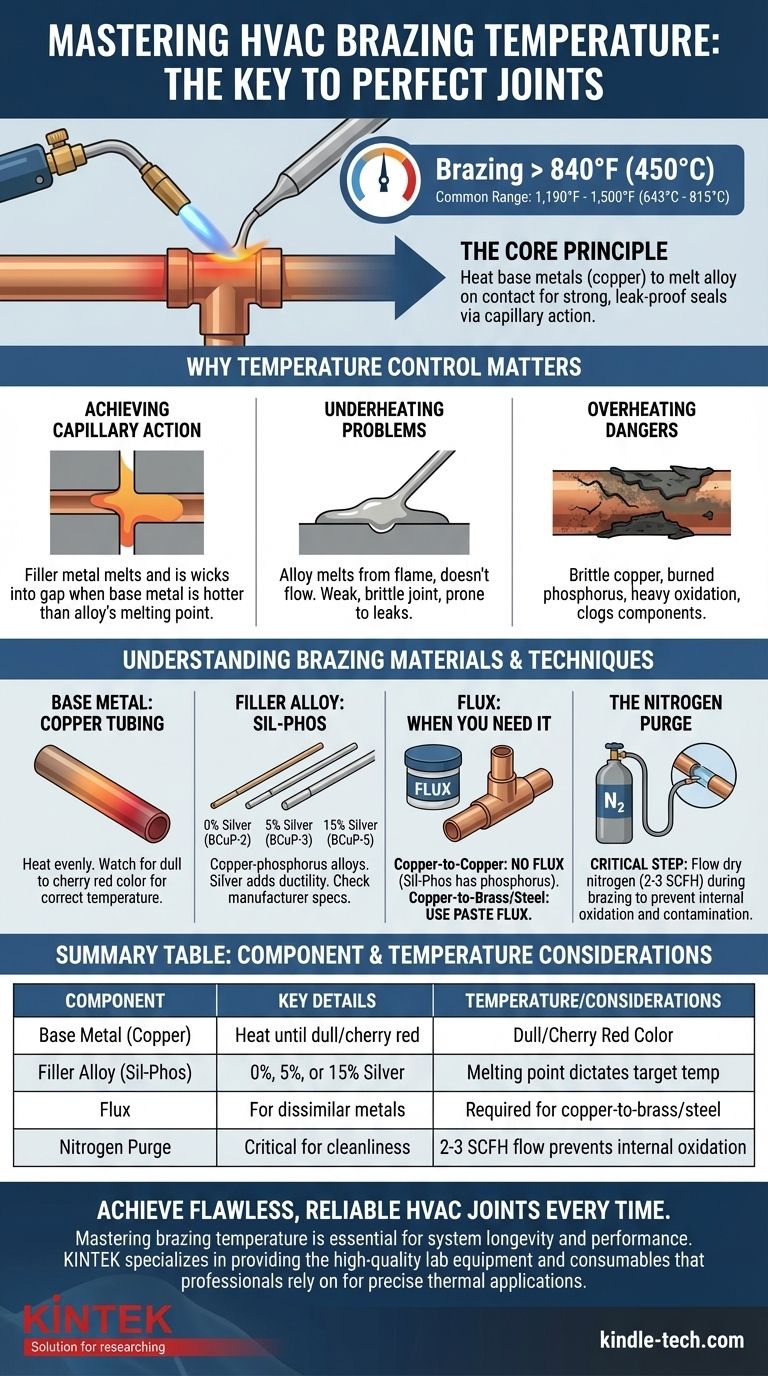

In HVAC, brazing is performed at temperatures above 840°F (450°C), but the precise target temperature is dictated by the specific filler metal alloy being used. For the common copper and sil-phos alloys in refrigeration systems, this typically falls within a working range of 1,190°F to 1,500°F (643°C to 815°C).

The core principle of brazing isn't about the temperature of your torch flame, but about heating the base metals (the copper tubing) until they are hot enough to melt the brazing alloy on contact. This ensures the filler metal is pulled deep into the joint by capillary action, creating a strong, permanent, and leak-proof seal.

Why Temperature Control is the Key to a Perfect Joint

A successful braze is a matter of physics, not force. The temperature of the copper tubing directly controls how the filler metal behaves. Getting it right is non-negotiable for the long-term reliability of an HVAC system.

Achieving Proper Capillary Action

Capillary action is the phenomenon where a liquid flows into a narrow space without assistance, often against gravity. For brazing to work, the filler metal must melt and be pulled into the tight gap between the pipe and the fitting.

This only happens when the base metal is at the correct temperature—hotter than the melting point of the filler alloy. The heated copper essentially "wicks" the molten alloy into the joint, creating a complete and uniform bond.

The Problem with Underheating

If the base metal is not hot enough, the brazing rod will melt from direct contact with the torch flame but won't flow properly into the joint.

This results in a poor bond where the alloy simply sits on the surface. The joint will be weak, brittle, and almost certain to leak under the high pressures of a refrigeration system.

The Dangers of Overheating

Excessive heat is just as damaging as insufficient heat. Overheating the copper can cause it to become brittle and can burn away the phosphorus in the filler alloy, which is essential for its flow.

More importantly, it creates heavy oxidation (a black, flaky scale) on both the inside and outside of the pipe. This oxidation prevents the filler metal from bonding to the copper and can break loose inside the system, clogging critical components like metering devices and compressor parts.

Understanding Your Brazing Materials

The temperature you aim for is a direct function of the materials you are joining. Each component plays a specific role in the process.

The Base Metal: Copper Tubing

In HVAC, the primary base metal is copper. Your goal is to heat the tubing and the fitting evenly. The key is to watch for the color of the copper; a dull to cherry red color indicates you are approaching the correct brazing temperature range.

The Filler Alloy: Sil-Phos

The most common filler metals for HVAC are copper-phosphorus alloys, often called sil-phos or sold under brand names like Sil-Fos. The percentage of silver in the alloy affects its properties:

- 0% Silver (BCuP-2): A cost-effective choice for copper-to-copper joints. It has a slightly higher melting temperature and is more brittle than silver-bearing alloys.

- 5% or 15% Silver (BCuP-3, BCuP-5): Adding silver lowers the melting point and increases the alloy's ductility, making it more resistant to vibration. This is often preferred for joints near the compressor.

Always check the manufacturer's specifications for the recommended working temperature of your specific brazing rod.

The Flux: When You Need It (and When You Don't)

Flux is a chemical cleaning agent that prevents oxidation and promotes the flow of filler metal.

- For Copper-to-Copper: You do not need flux when using a phos-copper (sil-phos) alloy. The phosphorus in the rod acts as the fluxing agent.

- For Copper-to-Brass or Steel: You must use a separate paste flux. The phosphorus in the rod is not sufficient to clean dissimilar metals like the brass in a service valve.

The Most Overlooked Step: The Nitrogen Purge

While heating the outside of the pipe, you must control the environment on the inside. Failing to do so is one of the most common and costly mistakes in HVAC work.

Why Internal Oxidation is Your Enemy

As you heat the copper, oxygen inside the pipe rapidly forms that black, flaky copper oxide scale. This scale does not stay put. Over time, it flakes off and circulates with the refrigerant and oil.

This contamination can clog the fine orifices of a thermostatic expansion valve (TXV), score compressor bearings, and lead to premature system failure.

The Solution: A Low-Pressure Purge

The solution is to purge the lines with dry nitrogen while you braze. By flowing a very low volume of nitrogen (2-3 SCFH) through the tubing, you displace all the oxygen.

This prevents any oxidation from forming on the inside surface of the pipe, ensuring the system remains perfectly clean. This is not an optional step; it is a hallmark of professional, reliable installation and repair.

Making the Right Choice for Your System

Your approach to brazing should be deliberate, with a clear understanding of the materials and the desired outcome.

- If your primary focus is a standard copper-to-copper joint: Use a sil-phos alloy and heat the joint until it reaches a cherry red color before introducing the rod.

- If your primary focus is joining copper to a brass valve: Apply a thin layer of white paste flux to both parts before heating and use a silver-bearing brazing alloy for superior bonding.

- If your primary focus is system longevity and reliability: Always, without exception, use a low-flow nitrogen purge to prevent internal contamination during every braze.

Ultimately, mastering brazing temperature is about understanding how to make the materials work for you to create clean, strong, and permanent connections.

Summary Table:

| Brazing Component | Key Details | Temperature/Considerations |

|---|---|---|

| Base Metal | Copper Tubing | Heat until dull/cherry red color appears. |

| Filler Alloy (Sil-Phos) | 0%, 5%, or 15% Silver | Melting point dictates target temperature. |

| Flux | For dissimilar metals (e.g., brass) | Required for copper-to-brass/steel joints. |

| Nitrogen Purge | Critical for cleanliness | 2-3 SCFH flow prevents internal oxidation. |

Achieve flawless, reliable HVAC joints every time.

Mastering brazing temperature is essential for system longevity and performance. KINTEK specializes in providing the high-quality lab equipment and consumables that professionals rely on for precise thermal applications.

Let us help you ensure every connection is perfect. Contact our experts today via our Contact Form to discuss your specific needs and how our solutions can support your work.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are alloys in simple words? Unlock the Power of Engineered Materials

- How are PTFE gaskets utilized for POEGMA electrolyte conductivity? Ensure Precision in Electrochemical Measurements

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- Why is PTFE wire used for hanging metal specimens in biodiesel corrosion tests? Ensure Pure Experimental Results