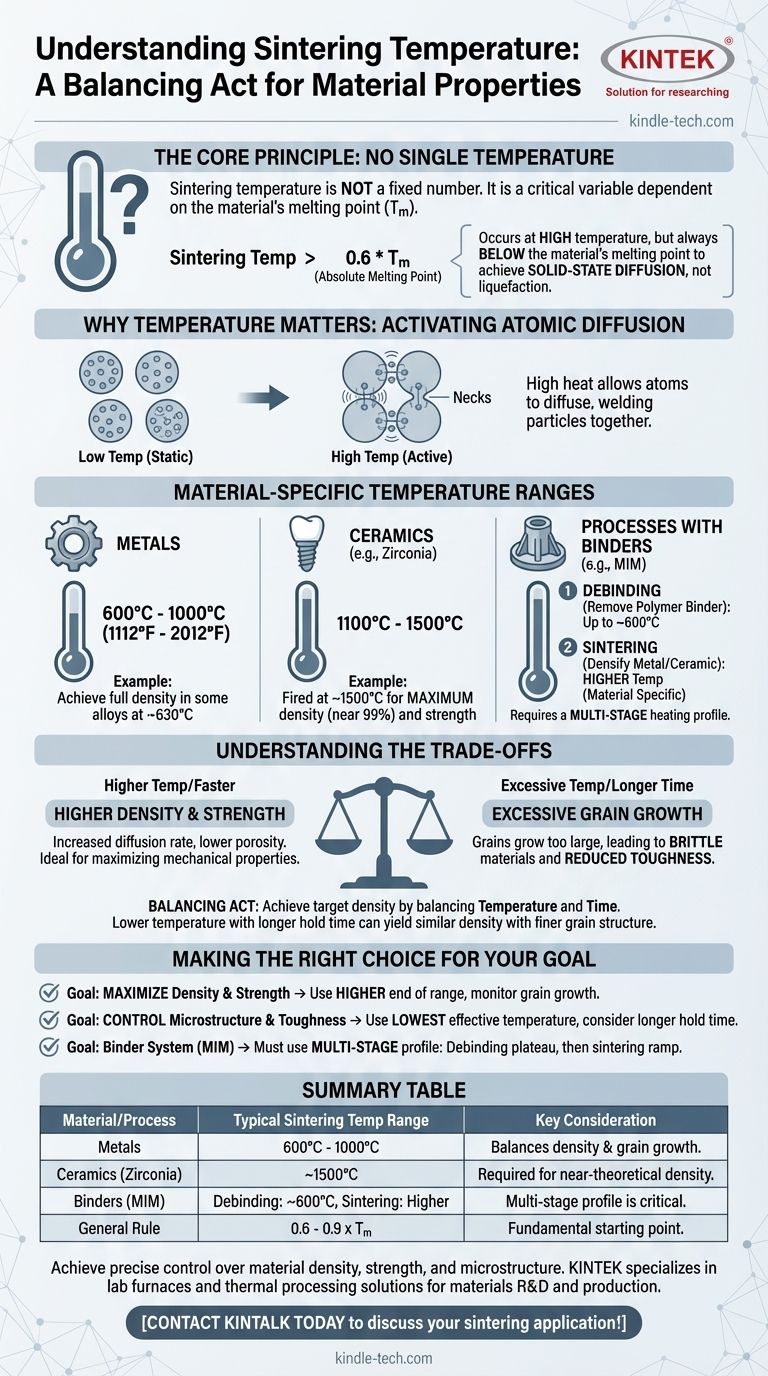

There is no single temperature for sintering; the correct temperature is entirely dependent on the specific material being processed. As a general rule, sintering occurs at a high temperature, typically above 0.6 times the absolute melting temperature (Tm) of the material. This provides the necessary thermal energy for atoms to fuse the powder particles together without melting the bulk material.

The core principle to understand is that sintering temperature is not a fixed number but a critical process variable. It is carefully selected based on a material's melting point to activate atomic diffusion, consolidating a powder into a solid mass while precisely controlling its final density and microstructure.

The Fundamental Principle: Why Temperature Matters

Sintering is a thermal process that gives powdered materials their strength and structure. The temperature is the single most important lever in controlling the outcome.

Activating Atomic Diffusion

Atoms in a solid are not static. Temperature is a measure of their vibration, and at high temperatures, atoms can move or "diffuse." Sintering harnesses this phenomenon. The high heat allows atoms at the contact points between powder particles to move across boundaries, effectively welding the particles together and reducing the overall surface area.

The "Rule of Thumb": Below Melting Point

Sintering always occurs below a material's melting point. The goal is solid-state diffusion, not liquefaction. The 0.6 * Tm guideline is a starting point, with most industrial processes operating between 0.6 and 0.9 times the melting temperature to balance speed and control.

From Natural Ores to Advanced Ceramics

This process is fundamental in both nature and industry. Geologically, it is how mineral deposits are compacted into dense ore over millennia. In manufacturing, it is the essential step for creating parts from metals, ceramics, and some plastics.

Sintering Temperatures for Common Materials

The required temperature varies dramatically by material class, highlighting the importance of material-specific knowledge.

Metals

Many metals are sintered in a range of 600°C to 1000°C (1112°F to 2012°F). However, the exact temperature is chosen to achieve a specific outcome. For some applications, a temperature of 630°C is sufficient to achieve full density in a particular metal alloy.

Ceramics (Zirconia Example)

Ceramics require significantly higher temperatures. Zirconia, a common dental and industrial ceramic, undergoes a critical crystalline phase change around 1100°C to 1200°C. However, to achieve maximum density (approaching 99%) and strength, furnaces will fire it at a much higher temperature, typically close to 1500°C.

Processes with Binders

In processes like Metal Injection Molding (MIM), a polymer binder is mixed with the metal powder. Before sintering can begin, this binder must be removed. This "debinding" step is a separate heating process that is typically completed by 600°C, after which the temperature is raised further for the actual sintering of the metal particles.

Understanding the Trade-offs

Choosing a sintering temperature is a balancing act between achieving desired properties and avoiding potential defects.

Higher Temperature for Higher Density

Generally, a higher sintering temperature increases the rate of atomic diffusion. This leads to faster and more complete consolidation, resulting in a final part with higher density, lower porosity, and greater mechanical strength. The Zirconia example, fired at 1500°C to achieve 99% density, perfectly illustrates this principle.

The Risk of Excessive Grain Growth

The primary downside of excessive temperature or time is grain growth. As particles fuse, the crystalline structures (grains) grow larger. While some growth is necessary, overly large grains can make a material more brittle and reduce its toughness. Controlling grain size is often just as important as maximizing density.

Balancing Time and Temperature

Sintering results are a function of both temperature and time. You can sometimes achieve a similar density by sintering at a lower temperature for a longer duration. This approach is often used when fine grain structure is a critical requirement for the final component's performance.

Making the Right Choice for Your Goal

The optimal sintering temperature is determined by the end goal for your component. Use these principles as your guide.

- If your primary focus is maximizing density and strength: Use a temperature on the higher end of the material's established sintering range, but be mindful of the point of diminishing returns where grain growth becomes a problem.

- If your primary focus is controlling microstructure and toughness: Opt for the lowest effective temperature that can still achieve your target density, potentially compensating with a longer hold time.

- If you are working with a system that includes a binder: Your heating profile must be multi-staged, with a lower temperature plateau to safely burn out the binder before ramping up to the material's sintering temperature.

Understanding these relationships transforms sintering from a simple heating step into a powerful tool for engineering material properties with precision.

Summary Table:

| Material/Process | Typical Sintering Temperature Range | Key Consideration |

|---|---|---|

| Metals | 600°C - 1000°C (1112°F - 2012°F) | Balances density and grain growth. |

| Ceramics (e.g., Zirconia) | ~1500°C | Required for near-theoretical density (>99%). |

| Processes with Binders (e.g., MIM) | Debinding: Up to ~600°C; Sintering: Higher | Multi-stage profile is critical. |

| General Rule | 0.6 - 0.9 x Absolute Melting Point (Tm) | The fundamental starting point for all materials. |

Achieve precise control over your material's density, strength, and microstructure. The right sintering furnace and thermal profile are critical to your success. KINTEK specializes in lab furnaces and thermal processing solutions for materials R&D and production. Let our experts help you select the perfect equipment to meet your specific material goals.

Contact KINTALK today to discuss your sintering application!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the advantages of solid state sintering? Achieve High-Performance Parts Efficiently

- What is the thin film method? A Guide to Advanced Surface Engineering

- What happens in sample preparation? The Critical Step for Accurate Lab Analysis

- What affects the pressure of an object? Master the Force and Area Relationship for Better Engineering

- What are the primary uses of Ultra-Low Temperature (ULT) freezers in laboratories? Preserve Your Most Valuable Samples

- What is a filter tester? A Guide to Measuring Filtration Efficiency & Performance

- What biomass is used for pyrolysis? Align Feedstock with Your Process for Optimal Bio-Oil, Biochar, or Fuel

- What are the disadvantages of KBr FTIR? Key Limitations That Impact Your Data Quality