The temperature of an annealing furnace is not a single value but a highly variable parameter, fundamentally dependent on the furnace type and the specific material being processed. While some hydrogen furnaces operate up to 1600°C and induction furnaces can exceed 1800°C, the precise temperature is determined by the metallurgical requirements of the annealing process itself.

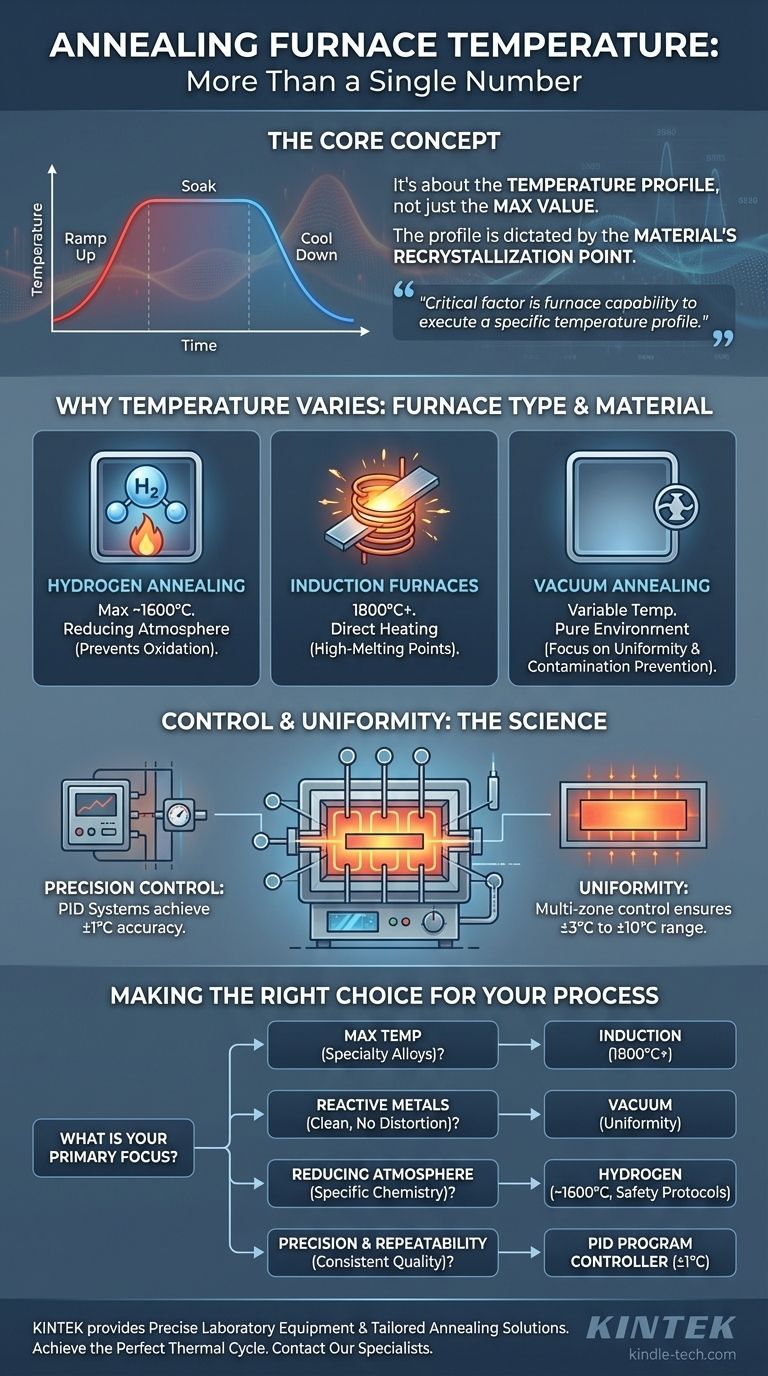

The critical factor is not a static furnace temperature, but rather the furnace's capability to precisely execute a specific temperature profile—including heating, soaking, and cooling—required for a given material and its desired final properties.

Why Temperature Varies: Furnace Type and Material

The term "annealing furnace" covers several distinct technologies, each with different operating characteristics and temperature ranges. The correct temperature is dictated by the material's properties.

Hydrogen Annealing Furnaces

These furnaces use a hydrogen atmosphere to prevent oxidation and create a reducing environment. They typically have a maximum operating temperature of around 1600°C. They are chosen when the material benefits from processing in a hydrogen environment.

Induction Furnaces

By using inductive coupling to heat the material directly, these furnaces can achieve extremely high temperatures. Depending on the design, they can reach 1800°C or even higher, making them suitable for materials with very high melting points or specialized annealing requirements.

Vacuum Annealing Furnaces

Vacuum furnaces remove atmosphere from the chamber to prevent oxidation and contamination. The focus here is less on a maximum temperature and more on creating a pure environment and ensuring exceptional temperature uniformity across the workpiece to prevent distortion.

The Role of the Material

Ultimately, the target temperature is set by the material's recrystallization point. This is the temperature at which the distorted grain structures created during cold working are replaced by new, stress-free grains. Different metals and alloys have vastly different recrystallization temperatures, dictating the required process.

The Science of Control and Uniformity

Modern furnaces are defined by their ability to control temperature with exceptional precision. The goal is not simply to reach a temperature, but to manage the entire thermal cycle repeatably.

Precision Control Systems

Furnaces achieve high accuracy, often within ±1°C, by using advanced control systems. These typically involve an intelligent PID (Proportional-Integral-Derivative) self-tuning controller that continuously adjusts power to the heating elements via a thyristor or solid-state module.

Programmed Temperature Profiles

Annealing is a process, not a single state. Furnaces utilize piecewise program controllers that can store and execute complex process curves. This allows operators to define the rate of temperature increase (ramp), the duration at peak temperature (soak), and the rate of cooling, all critical for achieving the desired metallurgical outcome.

Ensuring Temperature Uniformity

Uneven heating causes internal stresses and workpiece deformation. To prevent this, furnaces are often divided into multiple temperature control zones. Several temperature recorders monitor different locations, ensuring uniformity across the entire furnace, often within a range of ±3°C to ±10°C.

Understanding the Trade-offs and Safety Concerns

Choosing a furnace type involves balancing performance requirements with operational complexity and safety protocols. Each system presents a unique set of considerations.

Atmospheric vs. Vacuum Furnaces

The choice between a controlled atmosphere (like hydrogen) and a vacuum depends on the material's sensitivity to oxidation and other contaminants. Vacuum furnaces provide the purest environment but can be more complex, while atmospheric furnaces are tailored for specific chemical interactions.

The Risks of Hydrogen Furnaces

Hydrogen is highly effective as a reducing agent but introduces significant safety risks. It is crucial to prevent any hydrogen leakage into the surrounding air, as this can lead to spontaneous combustion and explosion accidents at high temperatures. Robust air circuit, water, and pressure control systems are mandatory.

Power Grid Impact

The high power demands of industrial furnaces can affect the local power grid. To mitigate this, some heating systems incorporate components like a magnetic transformer and power regulator, which help smooth the electrical load and reduce power grid pollution.

Making the Right Choice for Your Process

Your decision should be guided by the specific demands of your material and the desired outcome of the annealing cycle.

- If your primary focus is maximum temperature for specialty alloys: An induction furnace is likely necessary, as it is capable of reaching 1800°C or higher.

- If your primary focus is processing reactive metals without oxidation: A vacuum furnace offers the cleanest environment, prioritizing temperature uniformity to prevent part distortion.

- If your primary focus is achieving a specific reducing atmosphere: A hydrogen furnace, with a typical maximum of 1600°C, is the correct tool, but it demands strict adherence to safety protocols.

- If your primary focus is precision and repeatability for consistent quality: Prioritize a furnace with an advanced PID program controller capable of executing complex heating and cooling curves with ±1°C accuracy.

Ultimately, selecting the right furnace is about matching its specific temperature capabilities and control systems to your precise material and process requirements.

Summary Table:

| Furnace Type | Typical Max Temperature | Key Feature |

|---|---|---|

| Hydrogen Furnace | Up to 1600°C | Prevents oxidation with a reducing atmosphere |

| Induction Furnace | 1800°C or higher | Direct heating for high-melting-point materials |

| Vacuum Furnace | Varies, focus on uniformity | Pure environment to prevent contamination and distortion |

Struggling to select the right annealing furnace for your specific material and temperature profile?

At KINTEK, we specialize in providing precise laboratory equipment, including annealing furnaces tailored to your exact needs. Whether you require the extreme temperatures of an induction furnace, the clean environment of a vacuum furnace, or the specific atmosphere of a hydrogen system, our experts will help you achieve the perfect thermal cycle for your materials.

We provide:

- Furnaces with advanced PID control for ±1°C accuracy

- Systems ensuring temperature uniformity within ±3°C to ±10°C

- Solutions for materials with recrystallization points from standard alloys to high-temperature specialties

Let KINTEK enhance your lab's capabilities with reliable, precise, and safe annealing solutions. Contact our specialists today for a personalized consultation to discuss your specific annealing requirements and find the ideal furnace for your laboratory.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing