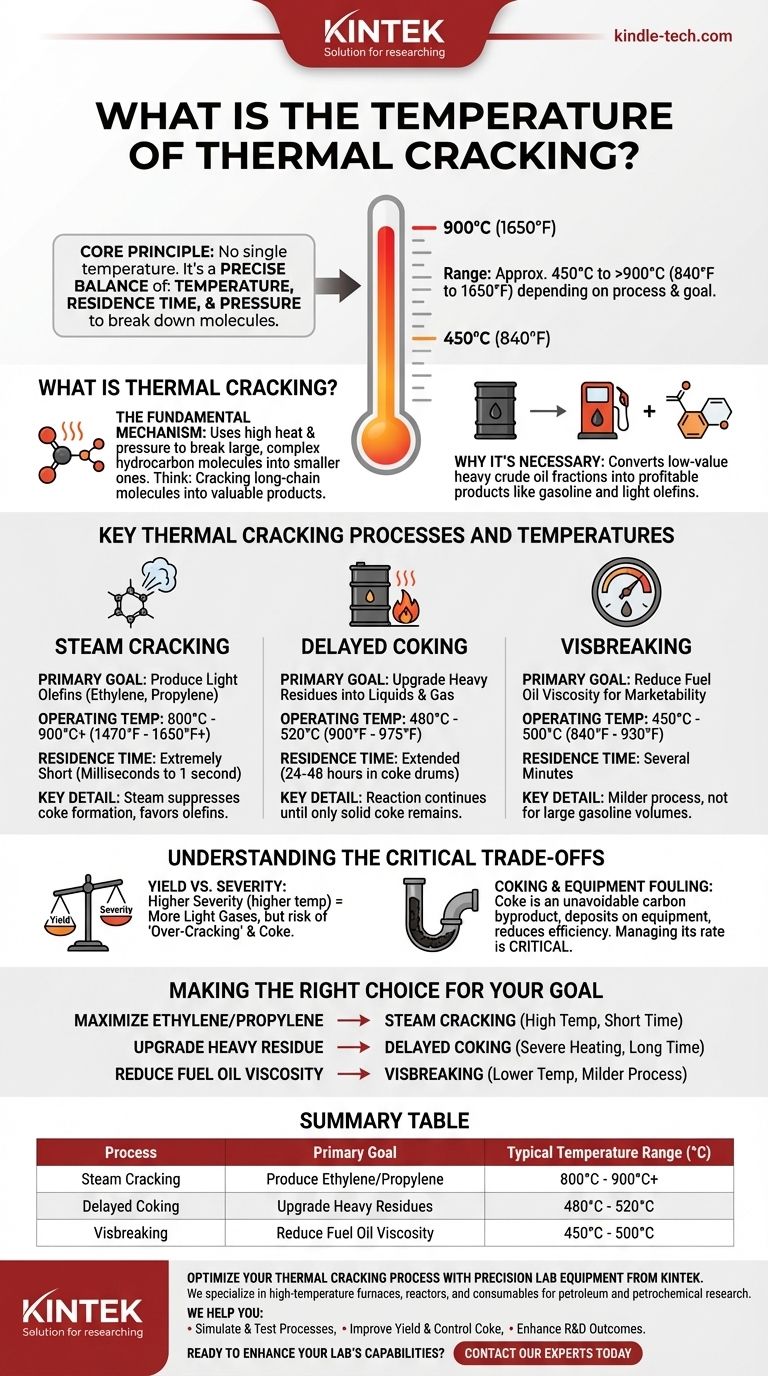

The temperature for thermal cracking ranges from approximately 450°C to over 900°C (840°F to 1650°F), depending on the specific process and the desired outcome. Processes like steam cracking use extremely high temperatures for very short periods to produce light olefins, while visbreaking uses lower temperatures for longer durations to reduce the viscosity of heavy fuel oil.

The core principle to understand is that there is no single temperature for thermal cracking. Instead, it is a precisely controlled balance between temperature, residence time, and pressure, which are manipulated to break down large hydrocarbon molecules into a specific mix of smaller, more valuable products.

What is Thermal Cracking?

The Fundamental Mechanism

Thermal cracking is a refining process that uses high heat and pressure to break large, complex hydrocarbon molecules into smaller, lower molecular weight molecules. It is one of the oldest and most fundamental conversion processes in the petroleum industry.

Think of it as using thermal energy to "crack" long-chain molecules into a mix of more valuable products, such as gasoline, kerosene, and light olefins like ethylene and propylene.

Why It's Necessary

Crude oil contains a wide variety of hydrocarbons, many of which are too large and heavy for direct use as high-value products like gasoline. Thermal cracking allows refiners to convert low-value heavy oils and residues into a more profitable product slate.

Key Thermal Cracking Processes and Temperatures

The specific operating temperature is tailored to the type of feedstock being processed and the products that are most desired.

Steam Cracking

Steam cracking is a high-severity process used to produce fundamental petrochemical building blocks. The primary products are light olefins, especially ethylene and propylene.

- Operating Temperature: 800°C - 900°C (1470°F - 1650°F), or even higher.

- Residence Time: Extremely short, often in the range of milliseconds to one second.

- Key Detail: Steam is added to the feedstock to reduce the partial pressure of the hydrocarbons, which suppresses coke formation and favors the production of valuable olefins.

Delayed Coking

Delayed coking is a severe form of thermal cracking designed to upgrade the heaviest refinery residues (the "bottom of the barrel") into more valuable liquid and gas products, leaving behind a solid petroleum coke.

- Operating Temperature: Feed is heated to 480°C - 520°C (900°F - 975°F) in a furnace.

- Residence Time: The heated feed then resides in large "coke drums" for an extended period (24-48 hours) where the cracking reactions continue until only coke remains.

Visbreaking

Visbreaking (viscosity breaking) is a milder thermal cracking process. Its primary goal is not to create large volumes of gasoline, but to reduce the viscosity of heavy fuel oil to make it more fluid and marketable.

- Operating Temperature: 450°C - 500°C (840°F - 930°F).

- Residence Time: Relatively longer than steam cracking, typically several minutes.

Understanding the Critical Trade-offs

The effectiveness and profitability of thermal cracking hinge on managing a delicate balance between reaction conditions and operational constraints.

Yield vs. Severity

The term severity refers to the intensity of the cracking conditions, primarily driven by temperature and residence time.

Higher severity (e.g., higher temperature) leads to more extensive cracking, which increases the yield of light gases like ethylene. However, pushing severity too high can "over-crack" the molecules, producing excessive amounts of low-value methane and solid coke.

Coking and Equipment Fouling

Coke is an unavoidable, carbon-rich byproduct of thermal cracking. It deposits on the inside of furnace tubes and other equipment.

This fouling reduces heat transfer efficiency and increases pressure drop, forcing periodic shutdowns for cleaning. Managing the rate of coke formation is the single most important operational challenge in any thermal cracking unit.

Making the Right Choice for Your Goal

The optimal temperature and process are dictated entirely by the economic objective and the available feedstock.

- If your primary focus is maximizing ethylene and propylene for petrochemicals: You must use the very high temperatures and short residence times characteristic of steam cracking.

- If your primary focus is upgrading heavy, viscous residue into lighter fuels: The severe heating and long residence time of a delayed coker are the appropriate choice.

- If your primary focus is simply making heavy fuel oil marketable by reducing its viscosity: A lower-temperature, milder process like visbreaking is the most economical solution.

Ultimately, controlling temperature in thermal cracking is about precisely steering chemical reactions toward the most profitable set of products.

Summary Table:

| Process | Primary Goal | Typical Temperature Range (°C) |

|---|---|---|

| Steam Cracking | Produce Ethylene/Propylene | 800°C - 900°C+ |

| Delayed Coking | Upgrade Heavy Residues | 480°C - 520°C |

| Visbreaking | Reduce Fuel Oil Viscosity | 450°C - 500°C |

Optimize your thermal cracking process with precision lab equipment from KINTEK.

Whether you are developing new catalysts, analyzing feedstocks, or monitoring process efficiency, the right equipment is critical for success. KINTEK specializes in high-temperature furnaces, reactors, and consumables designed to meet the rigorous demands of petroleum and petrochemical laboratories.

We help our customers:

- Simulate and test cracking processes accurately.

- Improve yield and control coke formation.

- Enhance research and development outcomes.

Ready to enhance your lab's capabilities? Contact our experts today to find the perfect solution for your thermal processing needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis