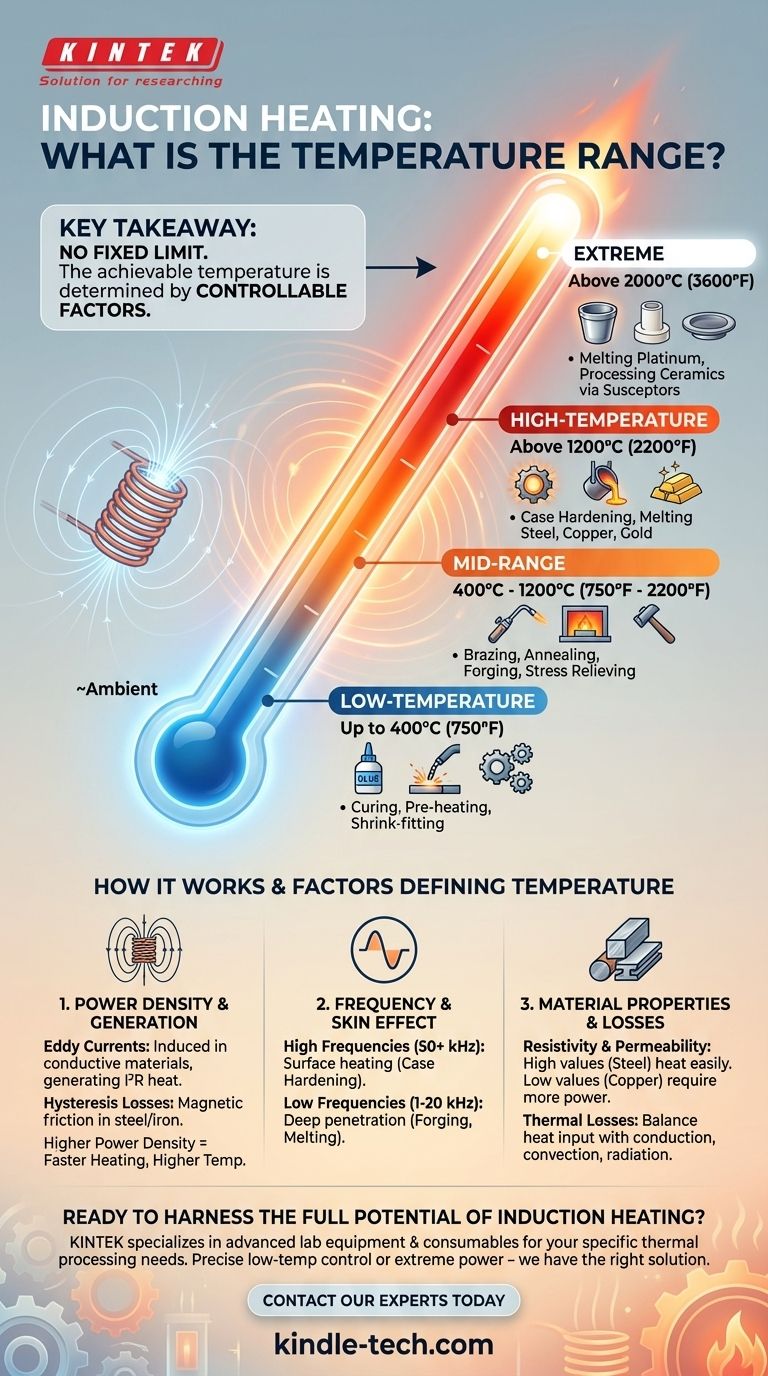

In principle, the temperature range for induction heating is exceptionally wide, capable of heating conductive materials from just above ambient temperatures to well over 3000°C (5432°F). The final temperature is not an inherent limit of the technology itself, but rather a result of the balance between the power induced in the material and the heat lost to the environment. This makes it one of the most versatile thermal processing methods available.

The critical takeaway is that induction heating doesn't have a fixed temperature limit. Instead, the achievable temperature for your specific application is determined by controllable factors: the power and frequency of the induction system, and the physical properties of the material you are heating.

How Induction Generates Temperature

To understand the temperature range, you must first understand how the heat is generated. It's a non-contact process driven by fundamental electromagnetic principles.

The Role of Eddy Currents

An induction heater's coil generates a powerful, rapidly alternating magnetic field. When a conductive workpiece (like a metal part) is placed within this field, the field induces circular electrical currents within the material. These are called eddy currents.

Due to the material's natural electrical resistance, the flow of these eddy currents generates precise and instantaneous heat. This is the same principle as the I²R heating that occurs in any resistive wire.

Hysteresis Losses

In magnetic materials like iron and steel, there is a secondary heating effect. The rapid reversal of the magnetic field causes friction at a molecular level as the magnetic domains resist changing direction. This creates hysteresis losses, which also generate heat.

This effect only occurs in magnetic materials and ceases once the material is heated above its Curie temperature (around 770°C / 1420°F for steel), at which point it loses its magnetic properties.

Factors That Define the Achievable Temperature

The final temperature and the speed at which it is reached are a direct function of several key variables. Mastering these is the key to successful induction processing.

Power Density

This is the most significant factor. Power density refers to how much power is delivered to a specific surface area or volume of the workpiece. Higher power density leads to a faster rate of heating and a higher maximum temperature before heat losses become dominant.

Frequency Selection

The frequency of the alternating current in the coil determines how deep the heat penetrates the part. This is known as the skin effect.

- High Frequencies (50 kHz - 200+ kHz): Concentrate the eddy currents in a thin layer near the surface. This is ideal for applications like case hardening, where you need a hard surface without affecting the core.

- Low Frequencies (1 kHz - 20 kHz): Penetrate deeper into the material. This is used for through-heating large parts for forging or for melting large volumes of metal.

Material Properties

The material of the workpiece itself plays a crucial role. Electrical resistivity and magnetic permeability are the two most important properties.

Materials with high resistivity and high permeability (like carbon steel) heat very easily and efficiently. Materials with low resistivity (like copper or aluminum) are more challenging to heat and require significantly higher power and specialized coil designs.

Thermal Losses

A workpiece being heated simultaneously loses heat to its surroundings through conduction, convection, and radiation. The maximum temperature is reached when the rate of heat generated by induction equals the rate of heat lost. To reach very high temperatures, you must either increase the power input or reduce thermal losses, for example, by using insulating materials.

Practical Temperature Ranges by Application

While theoretically vast, the temperature range is best understood through its common industrial applications.

Low-Temperature Applications (Up to 400°C / 750°F)

These processes require gentle, controlled heating. Examples include pre-heating for welding, curing adhesives and coatings, and shrink-fitting mechanical components.

Mid-Range Applications (400°C - 1200°C / 750°F - 2200°F)

This is the broadest category and a core strength of induction. It includes processes like brazing, soldering, annealing, stress relieving, and forging, where precise control and rapid heating are paramount.

High-Temperature Applications (Above 1200°C / 2200°F)

This range is used for transformative processes. Case hardening of steel, for example, involves heating the surface above its transformation temperature (often >900°C) and then quenching it. Induction melting of metals like steel, copper, and gold also falls into this category.

Extreme Temperatures (Above 2000°C / 3600°F)

Reaching these temperatures is possible but highly specialized. It is used for melting refractory metals like platinum or for heating graphite susceptors to process non-conductive materials like ceramics at very high temperatures.

Understanding the Trade-offs and Limitations

Induction heating is powerful, but it is not a universal solution. Understanding its limitations is critical for proper application.

Material Compatibility

Induction can only directly heat materials that are electrically conductive. Non-conductive materials like most ceramics, glass, and plastics cannot be heated directly. The workaround is to use a conductive susceptor (like a graphite crucible) which is heated by induction and transfers its heat to the non-conductive material.

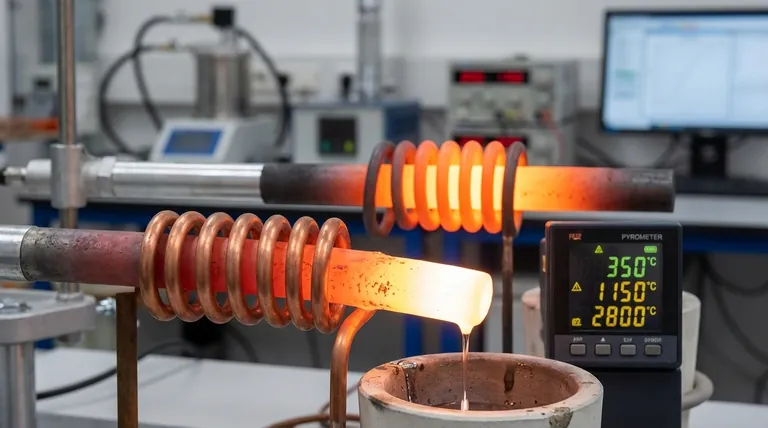

The Challenge of Temperature Control

While induction offers rapid heating, maintaining a specific temperature requires a sophisticated control system. This typically involves a pyrometer (for non-contact temperature measurement) or a thermocouple providing real-time feedback to the induction power supply, which then modulates its output to hold the target temperature.

Geometry and Coil Design

The effectiveness of induction heating is intrinsically linked to the design of the induction coil and its proximity to the workpiece. Complex part geometries can result in uneven heating, with some areas getting hotter than others. Proper coil design is an engineering discipline in itself and is critical to project success.

Making the Right Choice for Your Process

The versatility of induction means the optimal setup depends entirely on your goal.

- If your primary focus is surface hardening: You will need a high-frequency system to concentrate heat on the surface and high power density for rapid heating before the core is affected.

- If your primary focus is through-heating for forging: A low-frequency system is required to ensure deep energy penetration for a uniformly heated billet.

- If your primary focus is melting low-resistivity metals like aluminum: You must plan for a very high-power system and a carefully designed coil and crucible to overcome the material's tendency to resist heating.

- If your primary focus is precise temperature control for brazing: Your system specification must include a closed-loop temperature controller with a pyrometer or thermocouple feedback.

By matching the system's power and frequency to your material and process goals, you can harness induction heating for nearly any thermal application.

Summary Table:

| Application Category | Typical Temperature Range | Common Processes |

|---|---|---|

| Low-Temperature | Up to 400°C (750°F) | Adhesive curing, pre-heating, shrink-fitting |

| Mid-Range | 400°C - 1200°C (750°F - 2200°F) | Brazing, annealing, forging, stress relieving |

| High-Temperature | Above 1200°C (2200°F) | Case hardening, melting steel/copper/gold |

| Extreme | Above 2000°C (3600°F) | Melting platinum, processing ceramics via susceptors |

Ready to harness the full potential of induction heating for your laboratory or production process?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific thermal processing needs. Whether you require precise low-temperature control or the power to reach extreme heats, our expertise ensures you get the right induction heating solution for maximum efficiency and results.

Contact our experts today to discuss your application and discover how KINTEK can elevate your thermal processing capabilities.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is SiC elements? The Ultimate High-Temperature Heating Solution