In essence, magnetron sputtering is a highly controlled method for depositing atomic-scale thin films onto a surface within a vacuum. It is a type of physical vapor deposition (PVD) where a powerful magnetic field is used to enhance the efficiency of a process. In this process, high-energy gas ions bombard a source material (the "target"), physically knocking atoms loose, which then travel and condense onto a substrate to form a precise, uniform coating.

The core principle that distinguishes magnetron sputtering is its strategic use of a magnetic field to trap electrons near the target. This confinement dramatically increases the rate of gas ionization, creating a denser plasma that sputters the target material far more efficiently and at lower pressures than conventional sputtering methods.

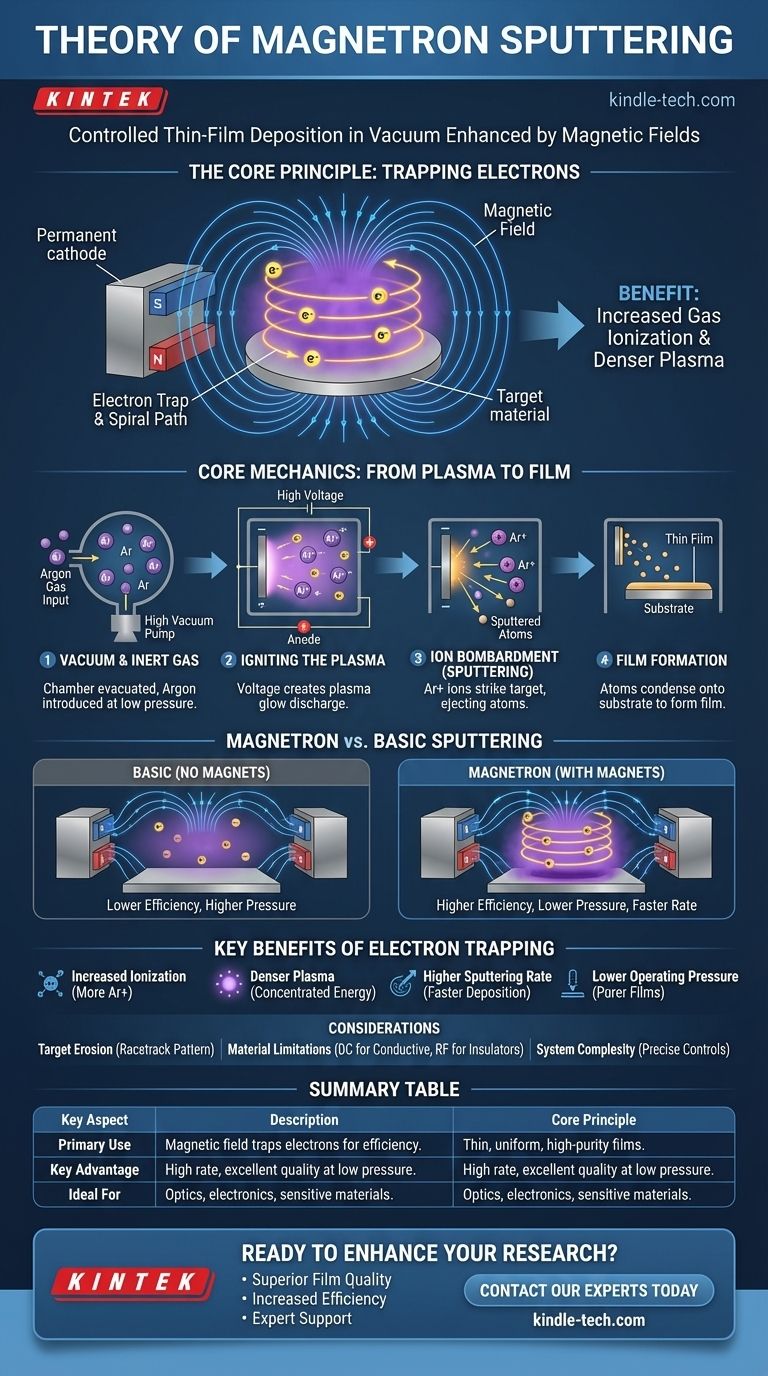

The Core Mechanics: From Plasma to Film

To understand the theory, it's best to break the process down into its fundamental stages, which occur inside a high-vacuum chamber.

Creating the Environment: Vacuum and Inert Gas

First, the chamber is pumped down to a high vacuum to remove air and other contaminants that could interfere with the process or contaminate the final film.

An inert gas, most commonly Argon (Ar), is then introduced into the chamber at a very low pressure. This gas is not part of the final coating; it serves as the medium for bombardment.

Igniting the Plasma: The Glow Discharge

A high negative DC or RF voltage is applied to the target material, which acts as the cathode. The chamber walls or a separate electrode act as the anode.

This strong electric field energizes the environment, stripping electrons from some of the Argon atoms. This creates a mixture of positively charged Argon ions (Ar+) and free electrons, forming a self-sustaining, energized state of matter known as plasma, which often emits a characteristic colorful light or "glow discharge."

The Sputtering Event: Ion Bombardment

The positively charged Argon ions (Ar+) are strongly attracted to the negatively charged target. They accelerate toward the target, striking its surface with significant kinetic energy.

This collision is a purely physical momentum transfer. The impact has enough force to dislodge or "sputter" neutral atoms from the target material, ejecting them into the vacuum environment.

Film Formation: Deposition on the Substrate

The sputtered atoms from the target travel in straight lines through the low-pressure chamber until they strike a surface.

When these atoms land on the strategically placed substrate (the object to be coated), they condense and bond to it, gradually building up a thin, highly uniform film.

The Magnetron's Critical Role: Enhancing Efficiency

The process described above is simple sputtering. The addition of a magnetron—a configuration of permanent magnets placed behind the target—is what makes the technique so powerful and widely used.

The Problem with Basic Sputtering

Without a magnetic field, the process is inefficient. Secondary electrons released from the target during ion bombardment travel quickly to the anode without colliding with many Argon atoms. This requires higher gas pressures to sustain the plasma, which reduces the quality of the film and slows the deposition rate.

Trapping Electrons with a Magnetic Field

The magnetron creates a magnetic field that is parallel to the target's surface. This field traps the light and fast-moving secondary electrons, forcing them into a long, spiral (cycloidal) path directly in front of the target.

The Benefits of Electron Trapping

This electron trapping has several profound effects:

- Increased Ionization: Because the electrons travel a much longer path, their probability of colliding with and ionizing neutral Argon atoms increases dramatically.

- Denser Plasma: This leads to the creation of many more Ar+ ions, resulting in a significantly denser plasma that is concentrated exactly where it's needed—near the target.

- Higher Sputtering Rate: More Ar+ ions mean more bombardment events per second, which translates to a much faster and more efficient deposition process.

- Lower Operating Pressure: The enhanced efficiency allows the process to run at lower gas pressures, meaning the sputtered atoms encounter fewer gas collisions on their way to the substrate, resulting in a purer and denser film.

Common Pitfalls and Considerations

While powerful, the technique has inherent characteristics that must be managed for successful application.

Target Material Limitations

Standard DC magnetron sputtering works best with electrically conductive target materials. Coating with insulating or ceramic materials requires the use of Radio Frequency (RF) or pulsed-DC power supplies, which adds complexity to the system.

Non-Uniform Target Erosion

The magnetic field confines the plasma to a specific region on the target face. This causes sputtering to occur primarily in that area, creating a distinctive erosion "racetrack." This leads to less than 100% utilization of the target material.

System Complexity

Magnetron sputtering systems are sophisticated pieces of equipment. Achieving high-quality, repeatable results requires precise control over multiple variables, including vacuum level, gas flow, power delivery, and substrate temperature.

Making the Right Choice for Your Goal

Understanding these principles helps clarify when magnetron sputtering is the superior choice for a coating application.

- If your primary focus is high-purity, dense films: Magnetron sputtering excels at creating high-quality coatings for optics, semiconductors, and electronics due to its low-pressure operation.

- If your primary focus is high-throughput manufacturing: The significantly faster deposition rates make it a highly efficient and scalable process for industrial applications like coating glass or tools.

- If your primary focus is coating temperature-sensitive substrates: The process confines the plasma's energy to the target, reducing heat load on the substrate and making it ideal for coating polymers and other delicate materials.

Ultimately, magnetron sputtering is a foundational technology in modern materials science, enabling the precise engineering of surfaces for countless advanced applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses a magnetic field to trap electrons, increasing plasma density and sputtering efficiency. |

| Primary Use | Depositing thin, uniform, high-purity films onto substrates like wafers, glass, or tools. |

| Key Advantage | High deposition rates and excellent film quality at lower operating pressures. |

| Ideal For | Applications requiring precise, dense coatings for optics, electronics, and sensitive materials. |

Ready to enhance your research or production with high-quality thin films?

The theory of magnetron sputtering is the foundation for creating the advanced coatings your projects demand. KINTEK specializes in providing state-of-the-art lab equipment and consumables for magnetron sputtering, serving the precise needs of laboratories and manufacturers.

We can help you achieve:

- Superior Film Quality: Dense, uniform coatings for critical applications.

- Increased Efficiency: Faster deposition rates to accelerate your workflow.

- Expert Support: Guidance on system selection and process optimization.

Let's discuss how magnetron sputtering can solve your coating challenges. Contact our experts today to find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is physical Vapour deposition method of nanomaterials? A Guide to High-Performance Thin Films

- What is Photochemical CVD? Discover Its Key Advantages in Advanced CMOS Technology

- What is physical vapor deposition on plastic? Upgrade Plastic Parts with Durable, Functional Coatings

- What is the thin film deposition method? A Guide to PVD & CVD Techniques

- How thin are thin films? Unlocking the Power of Nanometer-Scale Materials

- How does a CVD furnace ensure uniformity in nickel nanofilms? Achieve High-Precision Material Growth

- How does metal laser sintering work? Unlock Complex, Dense Metal Parts in Days

- How is Medium Temperature Chemical Vapour Deposition (MTCVD) applied in tool manufacturing? Enhance Carbide Tool Life