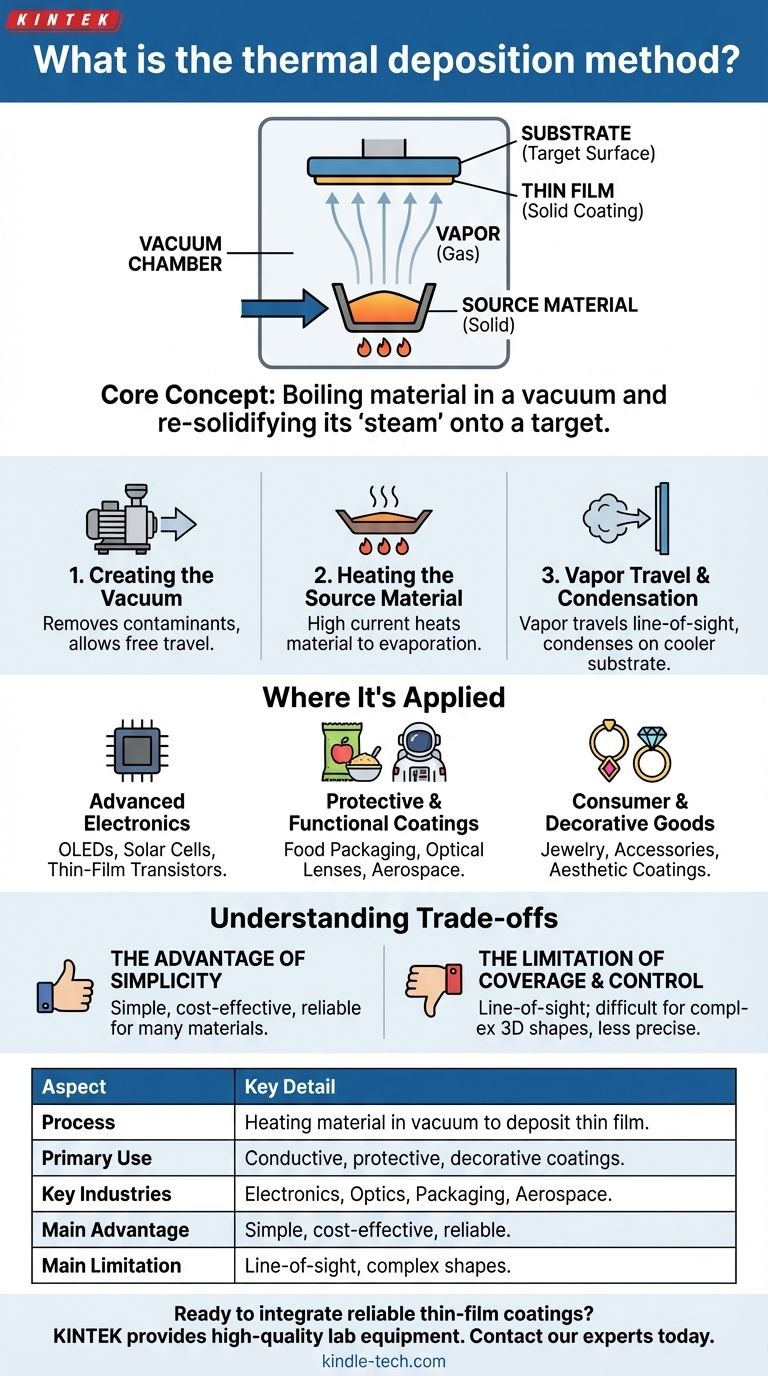

At its core, thermal deposition is a method for creating an ultra-thin film of material on a surface. In a high-vacuum chamber, a source material is heated until it evaporates, turning from a solid into a vapor. This vapor then travels through the vacuum and condenses onto a cooler target surface, known as a substrate, forming a solid, uniform coating.

The central concept is simple: you are essentially boiling a material in a vacuum and letting its "steam" re-solidify onto a target. This straightforward principle makes thermal deposition one of the most fundamental and widely used techniques in the thin-film industry.

How Thermal Deposition Works: A Step-by-Step Breakdown

To truly understand this method, it's best to break it down into its three critical phases. Each step is essential for achieving a high-quality, pure thin film.

Phase 1: Creating the Vacuum

The entire process must occur in a high-vacuum environment. This is non-negotiable for two key reasons.

First, the vacuum removes air and other gas molecules that could react with the hot vapor, contaminating the final film. Second, it allows the evaporated material atoms to travel freely and directly to the substrate without colliding with other particles.

Phase 2: Heating the Source Material

The material intended for the film is placed inside the chamber, typically in a small, electrically-resistant container called a "boat" or "basket."

A high electric current is passed through this container, causing it to heat up intensely. This heat is transferred to the source material, increasing its temperature until its atoms gain enough energy to leave the surface and enter a gaseous state, creating a vapor pressure.

Phase 3: Vapor Travel and Condensation

Once evaporated, the vapor stream travels in a straight, line-of-sight path from the source to the substrate.

The substrate is kept at a lower temperature than the vapor. When the hot vapor atoms strike the cooler surface, they rapidly lose energy, condense, and bond to the surface, building up layer by layer to form a solid thin film.

Where This Method is Applied

The simplicity and effectiveness of thermal deposition make it a vital process across numerous high-tech and consumer industries.

In Advanced Electronics

This method is crucial for depositing the ultra-thin metal layers that serve as conductors or bonding layers in devices like OLEDs, solar cells, and thin-film transistors.

For Protective and Functional Coatings

Thermal deposition is used to apply thin films of aluminum onto plastic for food packaging, creating a barrier against moisture and oxygen. It's also used for reflective coatings in NASA spacesuits, firefighter uniforms, and emergency blankets, as well as for anti-reflective and UV-protection layers on optical lenses.

In Consumer and Decorative Goods

The technique is widely used to apply lustrous, aesthetic thin-film coatings to jewelry and other accessories, providing a high-quality finish without a significant amount of material.

Understanding the Trade-offs

While powerful, thermal deposition is not the solution for every scenario. Understanding its advantages and limitations is key to using it effectively.

The Advantage of Simplicity

As one of the oldest technologies in the field, its primary strength is its straightforward nature. It does not require complex chemical precursors or reactive gases, making it a relatively cost-effective and reliable process for a wide range of materials, especially metals.

The Limitation of Coverage and Control

The process is fundamentally "line-of-sight," meaning the vapor travels in a straight line from the source to the substrate. This can make it difficult to uniformly coat complex, three-dimensional shapes with shadowed areas. Furthermore, control over the final film's structural properties (like density) can be less precise compared to more advanced deposition techniques.

Making the Right Choice for Your Application

Your specific goal will determine if thermal deposition is the ideal approach.

- If your primary focus is cost-effective metalization for packaging or simple electronics: Thermal deposition is an excellent, well-established choice for its reliability and efficiency.

- If your primary focus is creating high-purity optical or anti-reflective coatings: This method is highly effective due to the clean, controlled vacuum environment.

- If your primary focus is coating complex 3D shapes with perfect uniformity: You may need to investigate alternative methods, such as sputtering, that are not strictly line-of-sight.

Ultimately, thermal deposition remains a cornerstone of thin-film technology because of its fundamental effectiveness and elegant simplicity.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Heating a material in a vacuum to deposit a thin film on a substrate. |

| Primary Use | Creating conductive, protective, and decorative coatings. |

| Key Industries | Electronics, Optics, Packaging, Aerospace. |

| Main Advantage | Simple, cost-effective, and reliable for many materials. |

| Main Limitation | Line-of-sight process; less effective for complex 3D shapes. |

Ready to integrate reliable thin-film coatings into your production?

KINTEK specializes in providing high-quality lab equipment and consumables for thermal deposition and other thin-film processes. Whether you are developing advanced electronics, optical coatings, or protective layers, our expertise ensures you have the right tools for precise, efficient, and cost-effective results.

Contact our experts today to discuss how our solutions can meet your specific laboratory and production needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the vacuum evaporation mechanism? A Guide to High-Purity Thin Film Deposition

- How does evaporation deposition work? A Guide to High-Purity Thin Film Coating

- What are the alternatives to sputtering? Choose the Right Thin Film Deposition Method

- What is the process of e-beam coating? Achieve High-Purity, Precise Thin Films for Your Lab

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- Why is an alumina boat and Ti3AlC2 powder bed necessary for Ti2AlC sintering? Protect MAX Phase Purity

- What is the process of thermal evaporation? A Guide to Simple, Cost-Effective Thin-Film Deposition

- What are the advantages and disadvantages of evaporative deposition? Achieve High-Purity Thin Films