To be precise, the sputtering process operates under two distinct pressures. First, the vacuum chamber is pumped down to a low base pressure, typically below 1x10⁻⁶ Torr, to create a clean environment. Then, a working gas like argon is introduced, raising the pressure to a higher working pressure, often in the range of 1 to 100 mTorr, which is necessary to generate the plasma for the sputtering itself.

The core principle to understand is that sputtering pressure is not a single number, but a carefully controlled sequence. A very low base pressure ensures film purity, while a specific, higher working pressure dictates the quality and characteristics of the deposited film.

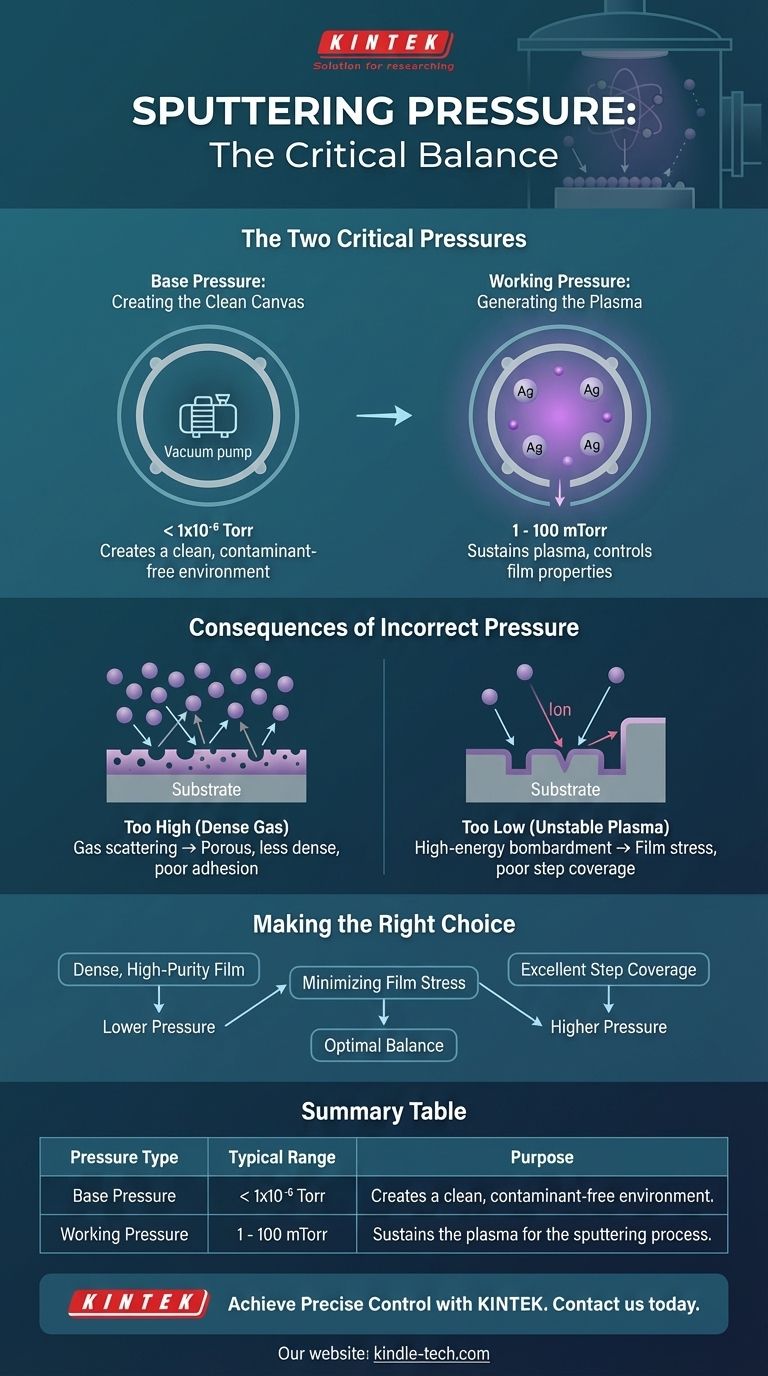

The Two Critical Pressures in Sputtering

Successful sputtering deposition is fundamentally dependent on managing two different pressure regimes inside the process chamber. Each serves a distinct and critical purpose.

Base Pressure: Creating the Clean Canvas

The first step is achieving a high vacuum, referred to as the base pressure. This involves removing ambient air and contaminants like water vapor and oxygen from the chamber.

A low base pressure, often below 1x10⁻⁶ Torr, is essential for minimizing the risk of impurities being incorporated into your thin film.

Materials that react easily with oxygen or water may require even lower base pressures to ensure the final film has the desired purity and performance characteristics.

Working Pressure: Generating the Plasma

Once a clean environment is established, a sputtering gas (most commonly argon) is introduced into the chamber. This raises the pressure to the "working pressure."

This pressure must be high enough to sustain a stable plasma when a voltage is applied. The plasma generates the energetic ions that bombard the target material.

The precise working pressure is a critical control parameter. It directly influences the energy of the bombarding ions and how sputtered atoms travel from the target to the substrate, which in turn affects the final film's quality.

The Consequences of Incorrect Pressure Control

Controlling the working pressure is a balancing act. Deviating from the optimal range for a given process has direct consequences on the properties of the deposited film.

What Happens if Pressure is Too High?

When the working pressure is too high, the sputtering gas becomes too dense. Atoms sputtered from the target will undergo more collisions with gas molecules on their way to the substrate.

This "gas scattering" reduces the energy of the depositing atoms, which can lead to films that are less dense, more porous, and have poorer adhesion.

What Happens if Pressure is Too Low?

If the working pressure is too low, it can be difficult to ignite and sustain a stable plasma.

Furthermore, with fewer gas molecules, there are fewer collisions to thermalize the sputtered atoms. This can lead to high-energy bombardment of the substrate, potentially causing film stress or damage. It can also result in poor step coverage on substrates with complex topographies.

Making the Right Choice for Your Film

Your target working pressure should be selected based on the desired characteristics of your final film. The choice is a trade-off between film density and substrate coverage.

- If your primary focus is a dense, high-purity film: A lower working pressure is generally preferred, as it minimizes gas scattering and allows atoms to arrive at the substrate with higher energy.

- If your primary focus is excellent step coverage on a complex surface: A higher working pressure may be necessary to increase gas scattering, which randomizes the arrival angle of the sputtered atoms, improving coverage on vertical sidewalls.

- If your primary focus is minimizing film stress: You must find an optimal pressure that balances energetic bombardment (at low pressures) with the formation of a porous microstructure (at high pressures).

Ultimately, mastering sputtering pressure is key to controlling the outcome of your deposition process.

Summary Table:

| Pressure Type | Typical Range | Purpose |

|---|---|---|

| Base Pressure | < 1x10⁻⁶ Torr | Creates a clean, contaminant-free environment in the chamber. |

| Working Pressure | 1 - 100 mTorr | Sustains the plasma for the sputtering process, controlling film properties. |

Achieve precise control over your thin film deposition process.

The correct sputtering pressure is critical for film purity, density, and adhesion. At KINTEK, we specialize in providing high-quality sputtering systems and expert support to help you optimize these parameters for your specific application. Whether you are developing advanced semiconductors, optical coatings, or protective layers, our team is ready to assist.

Contact us today to discuss your laboratory's sputtering needs and discover how our reliable equipment can enhance your research and production.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition