A batch furnace is a type of industrial or laboratory oven designed to process a specific, finite quantity of material—a "batch"—through a complete heating cycle. Its primary uses range from heat-treating small steel parts and sintering ceramics to conducting high-temperature experiments and melting metals for casting.

The fundamental purpose of a batch furnace is to provide highly controlled, uniform heat treatment to a single load of material at a time. This makes it invaluable for processes where precision, flexibility, and product-specific thermal cycles are more critical than continuous, high-volume output.

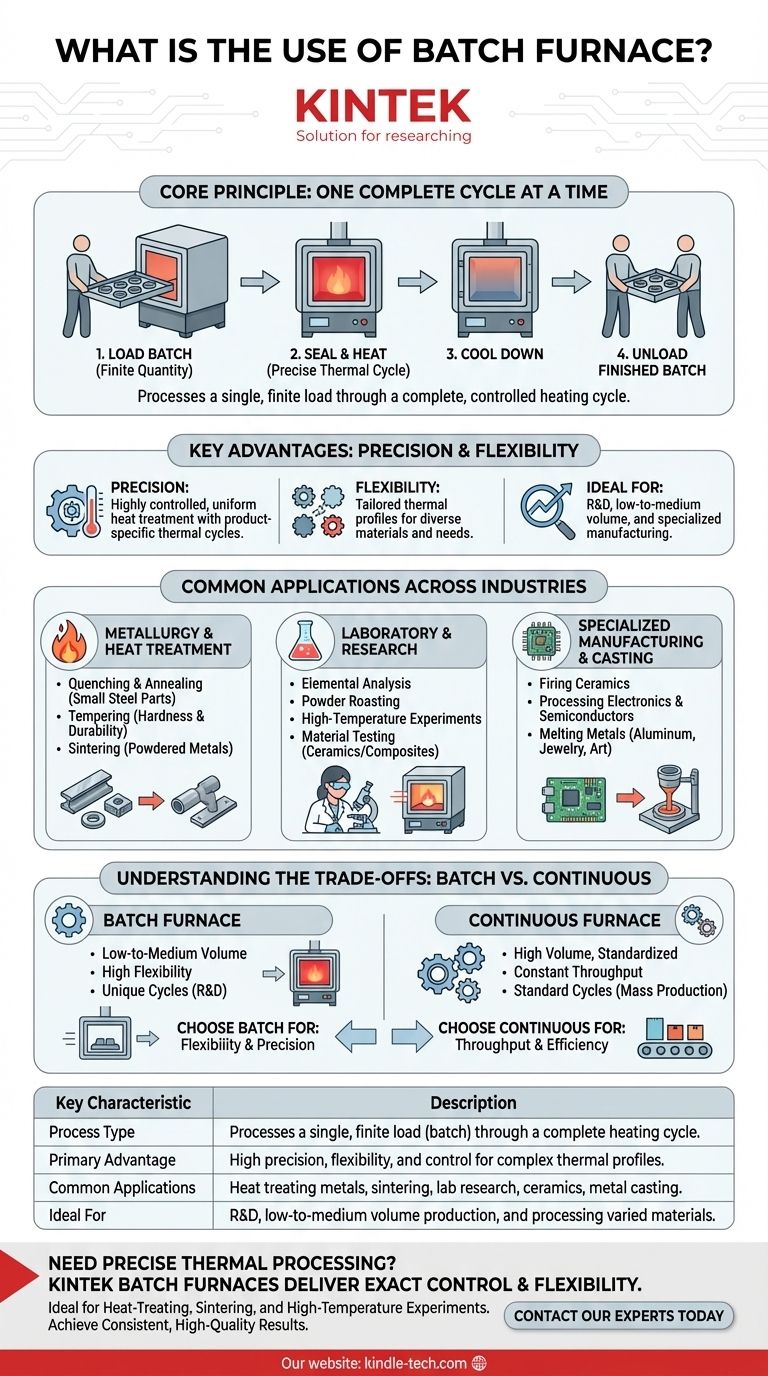

The Core Principle: One Complete Cycle at a Time

A batch furnace's operation is defined by its sequential process. Unlike a continuous furnace where material is constantly moving through, a batch furnace completes a full cycle on one load before it's ready for the next.

What Defines the "Batch" Process?

The process is a distinct, self-contained cycle: a batch of material is loaded into the furnace, the furnace is sealed, and the material is subjected to a specific temperature profile over time. Once the cycle of heating and cooling is complete, the furnace is opened, and the finished batch is unloaded.

The Key Advantage: Precision and Flexibility

This single-load approach gives operators immense control over the heating environment. It allows for highly specific and complex thermal profiles tailored to the exact needs of the material being processed, which is critical for research, development, and specialized manufacturing.

Common Applications Across Industries

The flexibility of batch processing makes these furnaces essential tools in a wide variety of fields, often appearing in forms like a box furnace or tube furnace.

Metallurgy and Heat Treatment

Batch furnaces are the standard for treating metal parts to alter their physical properties. Common applications include quenching, annealing, and tempering small steel components to achieve desired hardness and durability. They are also used for sintering powdered metals into a solid mass.

Laboratory and Research Settings

In scientific research, universities, and quality control labs, batch furnaces are indispensable. They are used for elemental analysis, powder roasting, conducting high-temperature experiments, and testing the thermal properties of novel materials like aerospace ceramics or composites.

Specialized Manufacturing and Casting

Industries requiring precise thermal control rely on batch furnaces. This includes firing ceramics, processing materials for electronics and semiconductors, and melting metals like aluminum for die casting operations, jewelry making, and art studios.

Understanding the Trade-offs: Batch vs. Continuous

Choosing the right type of furnace depends entirely on the operational goal. The primary trade-off is between the flexibility of a batch furnace and the throughput of a continuous one.

When to Choose a Batch Furnace

A batch furnace is the superior choice for low-to-medium volume production, research and development, or when processing a variety of different products that each require a unique thermal cycle. Its strength lies in its adaptability.

Limitations and Alternatives

The main limitation of a batch furnace is its lower throughput compared to a continuous furnace. For mass production of a single, standardized product, a continuous furnace that moves material along a conveyor through different heat zones is far more efficient.

Making the Right Choice for Your Goal

Selecting the correct thermal process requires a clear understanding of your primary objective.

- If your primary focus is research and development: A batch furnace provides the essential flexibility to test different materials and unique thermal cycles with precision.

- If your primary focus is heat-treating specialized or low-volume parts: The meticulous control of a batch process ensures consistent quality and adherence to strict specifications for each load.

- If your primary focus is high-volume, standardized production: You should investigate a continuous furnace, which is engineered for constant throughput and efficiency in mass manufacturing.

Ultimately, a batch furnace is the definitive tool when the quality and integrity of each individual process cycle is the most critical factor for success.

Summary Table:

| Key Characteristic | Description |

|---|---|

| Process Type | Processes a single, finite load (batch) through a complete heating cycle. |

| Primary Advantage | High precision, flexibility, and control for complex thermal profiles. |

| Common Applications | Heat treating metals, sintering, lab research, ceramics, metal casting. |

| Ideal For | R&D, low-to-medium volume production, and processing varied materials. |

Need precise thermal processing for your laboratory or specialized manufacturing?

KINTEK's batch furnaces are engineered to deliver the exact control and flexibility your work demands. Whether you're heat-treating specialized components, sintering materials for R&D, or conducting high-temperature experiments, our equipment ensures consistent, high-quality results for every batch.

Let us help you achieve your goals. Contact our experts today to find the perfect batch furnace solution for your specific needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control