At its core, a hydraulic pellet press is a specialized device used to compress loose powder into a dense, solid, and uniform disc, known as a pellet. While the general technology of hydraulic presses is used for heavy industrial tasks like forging metal, the pellet press serves a much more precise purpose, primarily in laboratory settings for preparing samples for sophisticated scientific analysis.

The fundamental problem a hydraulic pellet press solves is sample inconsistency. By transforming a loose, non-uniform powder into a solid, homogenous pellet, it ensures that analytical measurements are accurate, repeatable, and truly representative of the material being tested.

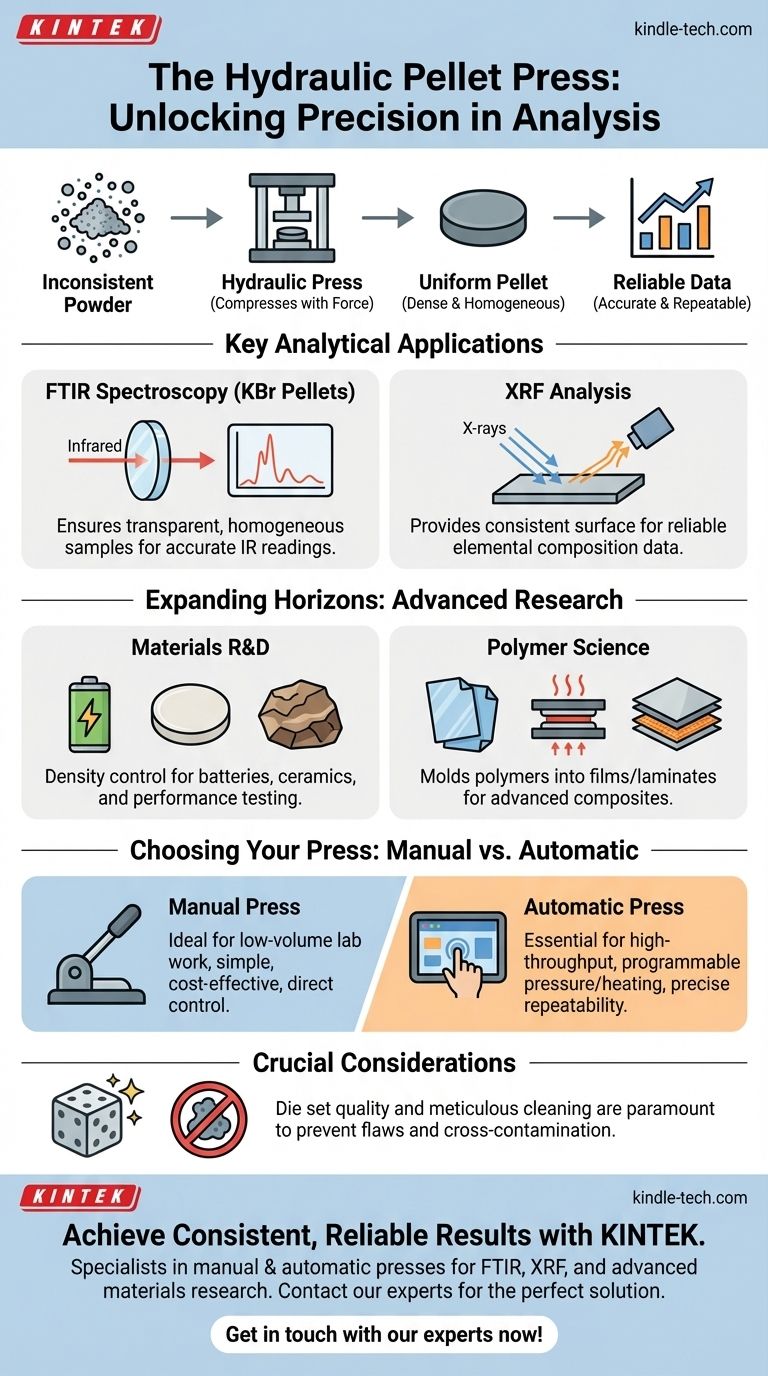

The Core Function: From Inconsistent Powder to Reliable Data

A hydraulic press uses an incompressible fluid to transmit and multiply force, allowing it to generate immense pressure in a compact device. A pellet press channels this force through a die set to compact material.

Why Compress Powder? The Need for Homogeneity

Loose powders have significant variations in density and particle distribution. When analyzed with techniques like spectroscopy, these inconsistencies can scatter or block the analytical beam (e.g., light or X-rays), leading to inaccurate and non-repeatable results.

Compressing the powder into a solid pellet eliminates air voids and creates a sample with a uniform density and a smooth surface. This ensures the analytical measurement is consistent across the entire sample.

Key Analytical Techniques Enabled by Pellets

The primary value of a pellet press is in sample preparation for spectroscopy.

KBr Pellets for FTIR Spectroscopy: In Fourier Transform Infrared (FTIR) analysis, a small amount of sample powder is mixed with potassium bromide (KBr) powder. This mixture is then pressed into a thin, semi-transparent pellet. The KBr is transparent to infrared light, allowing the spectrometer to measure the absorption of the sample material itself without interference.

Sample Pellets for XRF Analysis: In X-ray Fluorescence (XRF), the sample is bombarded with high-energy X-rays. A solid, flat pellet provides a perfect target, ensuring a consistent surface for excitation and measurement, which is critical for determining the elemental composition of a material.

Expanding Beyond Basic Analysis

While spectroscopic preparation is its most common use, the hydraulic press is a versatile tool in advanced research and manufacturing.

Materials Science and R&D

Researchers use hydraulic presses to develop and test new materials. The ability to create dense forms from powder is crucial for applications such as:

- Battery Electrodes: Compressing active materials into specific densities for performance testing.

- Ceramics and sputtering targets: Forming materials for use in electronics and high-tech coatings.

- Geological and Pharmaceutical Samples: Preparing rock or drug powders for compositional analysis.

- Advanced Composites: Fabricating materials for demanding environments, such as parts for rocket nozzles.

Polymer Science and Manufacturing

Automatic hydraulic presses, often equipped with heating elements, are used to melt and form polymers into thin films for testing or to laminate different materials together. They are also essential in forming sheet molded composites (SMC) and other advanced plastics.

Understanding the Trade-offs and Considerations

Choosing and using a press involves understanding its operational nuances to ensure reliable results.

Manual vs. Automatic Presses

A manual press, operated by a hand lever, is ideal for low-volume laboratory work where simplicity and cost-effectiveness are key. It provides direct control for a trained operator.

An automatic press offers programmable pressure, holding times, and often heating. This is essential for high-throughput industrial labs, R&D requiring precise repeatability, and complex processes like polymer molding.

The Critical Role of the Die Set

The press only provides the force; the die set forms the pellet. The quality, cleanliness, and handling of the die are paramount. A scratched or dirty die will produce a flawed pellet and can introduce contamination, invalidating the analysis.

Avoiding Sample Contamination

Because the press is used for precise analytical work, preventing cross-contamination between samples is critical. Dies must be meticulously cleaned after every use to ensure the integrity of the next sample.

Making the Right Choice for Your Goal

The right press depends entirely on your application's requirements for precision, throughput, and complexity.

- If your primary focus is routine spectroscopic analysis (FTIR/XRF): A standard manual hydraulic press is the workhorse for creating high-quality, consistent pellets for daily analytical needs.

- If your primary focus is materials R&D or polymer science: An automatic press with programmable controls and heating capabilities is necessary for process development and creating specialized samples.

- If your primary focus is high-volume industrial quality control: An automated system is essential to ensure high throughput and maintain strict consistency across hundreds or thousands of samples.

Ultimately, the hydraulic pellet press is an indispensable tool for transforming the uncertainty of raw powders into the certainty of reliable data.

Summary Table:

| Application | Primary Use of Pellet Press | Key Benefit |

|---|---|---|

| FTIR Spectroscopy | Create KBr pellets for analysis | Ensures transparent, homogeneous samples for accurate IR readings |

| XRF Analysis | Prepare flat, dense pellets for X-ray excitation | Provides consistent surface for reliable elemental composition data |

| Materials R&D | Compress powders for battery electrodes, ceramics, etc. | Enables density control and performance testing of new materials |

| Polymer Science | Mold polymers into films or laminates (with heated presses) | Allows for precise formation of advanced composites and prototypes |

Ready to achieve consistent, reliable results in your lab?

Whether you're preparing samples for FTIR, XRF, or advanced materials research, the right hydraulic pellet press is key to eliminating sample inconsistency and ensuring data accuracy.

KINTEK specializes in lab equipment and consumables, offering a range of manual and automatic hydraulic presses designed to meet your specific needs—from routine spectroscopic analysis to complex R&D projects. Our expertise ensures you get the precise tooling and support necessary for flawless sample preparation.

Contact us today to discuss your application and find the perfect press for your laboratory. Let KINTEK help you transform powders into precision.

Get in touch with our experts now!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- What role does a laboratory hydraulic press play in preparing solid model materials? Standardize for Precise Data.

- What is the function of a laboratory hydraulic press for Li10GeP2S12 pellets? Optimize Solid-State Battery Performance

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep