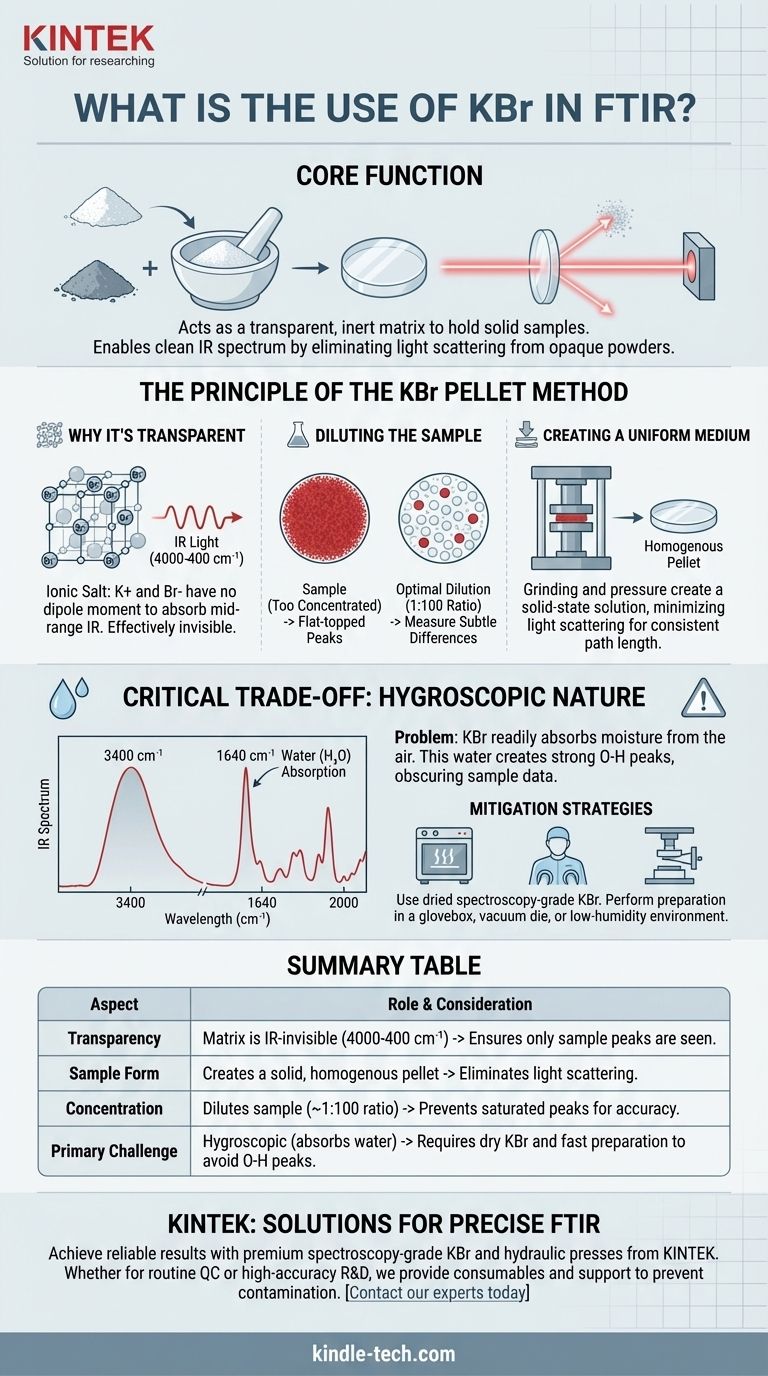

In Fourier-Transform Infrared (FTIR) spectroscopy, potassium bromide (KBr) is used as an inert and transparent matrix to hold solid samples for analysis. Because KBr is transparent to infrared light, it can be mixed with a small amount of a solid sample and compressed into a thin pellet. This pellet allows the spectrometer's IR beam to pass through and measure the sample's unique absorption spectrum without interference from the matrix itself.

The core function of KBr is to solve the problem of analyzing opaque solid powders. It acts as a transparent medium that dilutes the sample to the correct concentration and holds it in a uniform disc, eliminating light scattering and enabling a clean, measurable spectrum.

The Principle of the KBr Pellet Method

FTIR spectroscopy works by passing infrared light through a substance to see which frequencies are absorbed. For solid powders, this is impossible to do directly. The KBr pellet method is the classic solution to this problem.

Why KBr is Transparent to Infrared Light

Potassium bromide is an ionic salt. Its simple crystal lattice consists of potassium (K+) and bromide (Br-) ions. The bond between them has no significant dipole moment that can be excited by the frequencies of mid-range infrared radiation.

As a result, the KBr itself does not absorb IR light in the functional group region (4000-400 cm⁻¹), making it effectively invisible to the spectrometer. This ensures that any absorption peaks detected are from your sample, not the surrounding matrix.

Diluting the Sample to an Optimal Concentration

A common issue in transmission spectroscopy is using a sample that is too concentrated. If the sample is too thick or dense, it will absorb nearly all the IR light, leading to "flat-topped" peaks and a useless spectrum.

The KBr acts as a diluent. The typical ratio is about 1 part sample to 100 parts KBr. This precise dilution ensures the sample is present in a low enough concentration for the detector to measure subtle differences in absorption across the spectrum.

Creating a Solid, Uniform Medium

A loose powder scatters light in all directions, which severely degrades the quality of a spectrum. The KBr method overcomes this by creating a solid-state solution.

By grinding the sample with KBr and compressing it under high pressure (using a hydraulic press), you create a solid, glass-like disc. This homogenous pellet minimizes light scattering and provides a consistent path length for the IR beam, leading to a sharp and reproducible result.

Understanding the Critical Trade-off: Hygroscopic Nature

While KBr is an ideal matrix, it has one significant drawback: it is hygroscopic. This property is the most common source of error when preparing KBr pellets.

The Problem with Water Absorption

Hygroscopic materials readily absorb moisture from the atmosphere. As soon as a container of KBr is opened, it begins to attract water molecules from the air.

This absorbed water is not a passive contaminant; it is highly active in the infrared spectrum.

How Moisture Ruins a Spectrum

Water (H₂O) has a very strong, broad absorption band caused by O-H bond stretching, typically appearing around 3400 cm⁻¹. It also has a bending vibration around 1640 cm⁻¹.

If your KBr is "wet," these large water peaks will appear in your spectrum. They can easily obscure or completely overwhelm the peaks from your actual sample in those regions, making interpretation difficult or impossible.

Mitigation Strategies

To get a clean spectrum, you must minimize water contamination. The best practice is to use spectroscopy-grade KBr that has been thoroughly dried and kept in a desiccator or oven.

For the highest quality results, especially in humid environments, the grinding and pressing should be performed inside a glovebox with a dry atmosphere or by using a specialized vacuum die that removes air and moisture during compression.

Making the Right Choice for Your Goal

The quality of your KBr pellet directly determines the quality of your FTIR spectrum. Your preparation strategy should align with your analytical needs.

- If your primary focus is routine analysis of a stable compound: Ensure your KBr is dry, grind the mixture thoroughly, and adhere to the standard ~1:100 sample-to-KBr ratio for reliable results.

- If your primary focus is analyzing a sample with very weak absorption: You can slightly increase the sample concentration, but be prepared for a higher risk of light scattering and saturated peaks.

- If your primary focus is achieving the highest spectral accuracy: Work quickly in a low-humidity environment or, ideally, use a glovebox or vacuum die to eliminate any chance of water contamination.

Mastering the KBr pellet technique transforms solid sample analysis from a challenge into a routine, high-precision measurement.

Summary Table:

| Aspect | Role of KBr in FTIR | Key Consideration |

|---|---|---|

| Transparency | Matrix is IR-invisible (4000-400 cm⁻¹) | Ensures spectrum shows only sample peaks |

| Sample Form | Creates a solid, homogenous pellet | Eliminates light scattering from loose powder |

| Concentration | Dilutes sample (~1:100 ratio) | Prevents saturated peaks for accurate measurement |

| Primary Challenge | Hygroscopic (absorbs water from air) | Requires dry KBr and fast preparation to avoid O-H peaks (~3400 cm⁻¹) |

Achieve precise and reliable FTIR results for your solid samples.

The KBr pellet method is fundamental, but success depends on using high-quality, dry materials and proper technique. KINTEK specializes in supplying premium spectroscopy-grade KBr and reliable lab equipment, including hydraulic presses, designed specifically for consistent pellet preparation.

Whether your lab focuses on routine quality control or high-accuracy R&D, we provide the consumables and support to ensure your analyses are never compromised by contamination or poor preparation.

Contact our experts today to discuss your FTIR needs and ensure your lab is equipped for success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the purpose of using laboratory hydraulic presses for molecular sieve catalysts? Optimize Reactor Performance

- What is the potential application of a laboratory hydraulic press in zirconium hydrometallurgy? Bridge Your Research

- What is the XRF method of sampling? Achieve Accurate Elemental Analysis with Proper Sample Prep

- What is the cake thickness from a filter press? Optimize Your Filtration Cycle & Efficiency

- What is the role of a laboratory hydraulic press in photocatalytic testing? Enhance Catalyst Sample Precision

- What is the difference between mechanical press and hydraulic press? Speed vs. Control for Your Production

- What contribution does a laboratory hydraulic press make to the fabrication of HEA catalysts? Key Forming Role

- What products are made with a hydraulic press? From Car Parts to Cosmetics, Shaping Modern Manufacturing