At its core, a roller press machine is used for the high-pressure grinding of brittle, raw materials. It functions by drawing material between two counter-rotating rollers, which apply immense compressive force to crush and grind the particles. This process, known as interparticle comminution, is a highly efficient method for size reduction in several key industries.

The central purpose of a roller press is to drastically reduce energy consumption in grinding circuits. By using intense pressure to create micro-cracks and weaken material before it enters a traditional ball mill, it makes the entire size-reduction process significantly more efficient.

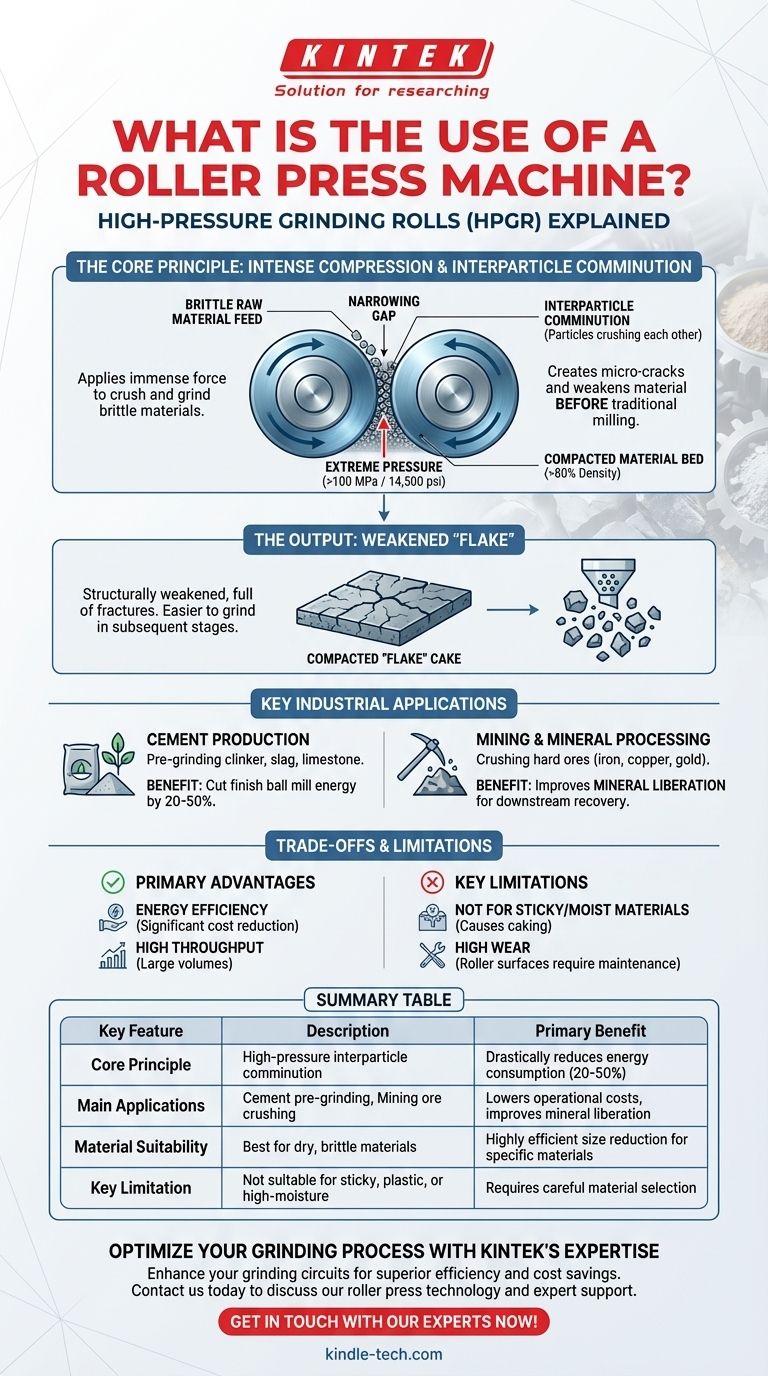

The Core Principle: High-Pressure Grinding Rolls (HPGR)

The technology behind the roller press is often referred to as High-Pressure Grinding Rolls, or HPGR. Understanding its mechanism reveals why it is so effective.

How It Works: Intense Compression

A roller press operates by feeding material into the gap between two rollers rotating in opposite directions. As the material is drawn into this narrowing gap, it is subjected to extremely high pressures, often exceeding 100 MPa (14,500 psi).

This pressure compacts the material bed to over 80% of its solid density.

Interparticle Comminution

Unlike a jaw crusher that crushes rock against a metal plate, the primary grinding action in a roller press happens within the material bed itself. Particles are crushed against other particles under immense force.

This interparticle comminution is highly energy-efficient and, crucially, induces a vast network of micro-cracks throughout the individual particles.

The Output: A Weakened "Flake"

The material exits the rollers as a compacted cake or "flake." This flake is then sent to a de-agglomerator to be broken apart.

The resulting individual particles are not just smaller; they are structurally weakened and full of fractures, making them much easier to grind in any subsequent processing stage, like a ball mill.

Key Industrial Applications

The unique efficiency of the roller press makes it a critical piece of equipment in industries where grinding is a major operational cost.

Cement Production

This is one of the most common applications. Roller presses are used for the pre-grinding of cement clinker, slag, and limestone. By pre-processing the clinker, the energy required by the power-hungry finish ball mills can be cut by 20-50%.

Mining and Mineral Processing

In hard rock mining (iron, copper, gold, diamonds), the roller press is used to crush ores. The micro-fractures it creates significantly improve mineral liberation, meaning the valuable minerals are more easily separated from the waste rock in downstream processes like leaching or flotation.

Other Bulk Materials

The technology is also applied to other brittle materials, such as kimberlite, coal, and various industrial minerals where efficient particle size reduction is required.

Understanding the Trade-offs and Limitations

While powerful, a roller press is not a universal solution. Its effectiveness is dependent on proper application and understanding its operational requirements.

The Primary Advantage: Energy Efficiency

The most significant benefit is a substantial reduction in specific energy consumption compared to traditional crushing and grinding circuits. This translates directly into lower operational costs.

High Throughput Capacity

Roller presses are capable of processing very large volumes of material, making them suitable for high-capacity industrial operations.

Limitation: Material Suitability

The technology is not suitable for all materials. It performs poorly with sticky, plastic, or high-moisture materials, which can cake onto the roller surfaces and cause severe operational issues. It is designed specifically for dry, brittle feed.

The Challenge of Wear

The roller surfaces are subjected to extreme abrasive wear. These surfaces, often studded with tungsten carbide, are a major maintenance item and a significant operational cost. Proper feed preparation and operational control are critical to managing wear life.

Making the Right Choice for Your Operation

Integrating a roller press is a strategic decision based on your material and primary goals.

- If your primary focus is reducing operational costs in cement production: A roller press is an essential tool for pre-grinding clinker to significantly cut the energy consumption of your finish mills.

- If your primary focus is improving liberation in hard rock mining: Implementing HPGR can create microfractures in ore particles, enhancing the efficiency of downstream recovery processes.

- If you are processing sticky or high-moisture materials: A roller press is likely unsuitable, and you should investigate alternative grinding technologies like SAG (Semi-Autogenous Grinding) mills.

Ultimately, a roller press leverages the elegant principle of high-pressure comminution to deliver superior energy efficiency for the right application.

Summary Table:

| Key Feature | Description | Primary Benefit |

|---|---|---|

| Core Principle | High-pressure interparticle comminution between two rollers | Drastically reduces energy consumption (20-50%) in grinding circuits |

| Main Applications | Cement clinker pre-grinding; crushing ores in mining (iron, copper, gold) | Lowers operational costs; improves mineral liberation for downstream processing |

| Material Suitability | Best for dry, brittle materials (e.g., clinker, limestone, hard ores) | Highly efficient size reduction for specific, compatible materials |

| Key Limitation | Not suitable for sticky, plastic, or high-moisture materials | Requires careful material selection to avoid operational issues and wear |

Optimize Your Grinding Process with KINTEK's Expertise

Are you looking to significantly reduce energy consumption and operational costs in your cement production or mineral processing plant? A roller press machine could be the key to achieving superior efficiency and cost savings.

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to your specific industrial needs. Whether you're in cement production, mining, or processing other brittle materials, our solutions are designed to enhance your grinding circuits and improve overall productivity.

Contact us today to discuss how our roller press technology and expert support can benefit your operation. Let us help you make a strategic, cost-effective choice for your size reduction challenges.

Get in touch with our experts now!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Heat Press Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance