At its core, a muffle furnace operates by using electrical resistance to generate intense heat within a highly insulated chamber. This chamber, known as the "muffle," isolates the material being heated from the actual heating elements, ensuring a clean, uniform, and precisely controlled thermal environment.

The defining principle of a muffle furnace is not just heating, but separation. The "muffle" is a physical barrier that protects the sample from direct contact with the heat source, preventing contamination and ensuring uniform heat transfer through radiation and convection.

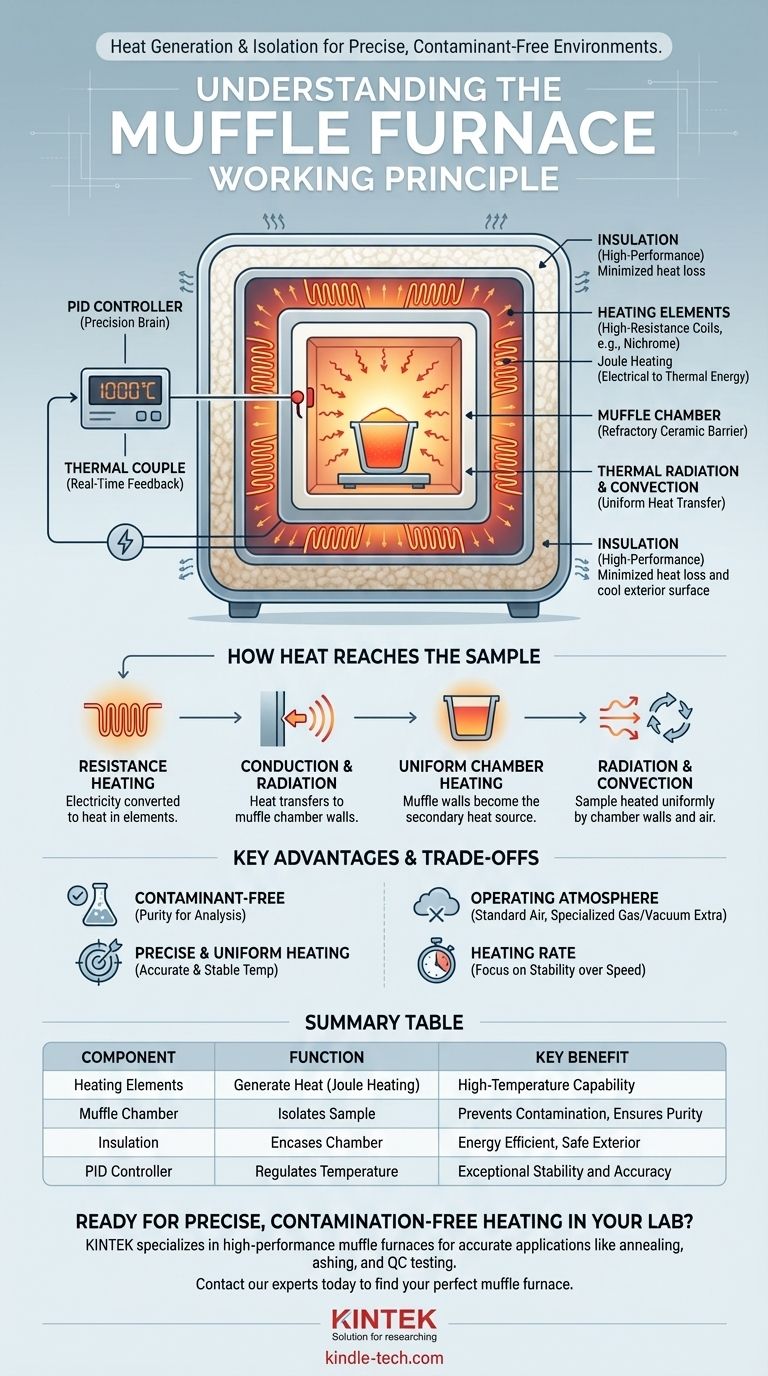

Deconstructing the Muffle Furnace

To understand the working principle, we must look at its four critical components and how they interact.

The Heating Elements

The heat generation begins with the heating elements, which are typically coils made from a high-resistance alloy like Nichrome. When a high electrical current is passed through these coils, they glow red-hot due to a phenomenon known as Joule heating—the conversion of electrical energy into thermal energy.

The Muffle Chamber

This is the heart of the furnace. The heating elements are positioned around the outside of a sealed chamber. This chamber is constructed from a dense, heat-resistant (refractory) ceramic material. This chamber is the muffle. It absorbs the heat from the glowing elements and transfers it to the interior space.

The Insulation

To achieve and maintain very high temperatures (often over 1000°C) efficiently, the entire muffle chamber and heating element assembly is encased in thick layers of high-performance thermal insulation. This minimizes heat loss to the surrounding environment, reduces energy consumption, and keeps the exterior of the furnace cool and safe to touch.

The Control System

A muffle furnace's precision comes from its electronic control system. A thermocouple, a highly sensitive temperature sensor, is placed inside the chamber to provide real-time temperature feedback. This data is fed to a PID (Proportional-Integral-Derivative) controller, which acts as the brain, precisely adjusting the power sent to the heating elements to maintain the set temperature with exceptional stability.

How Heat Reaches the Sample

The process of heating a sample inside the furnace involves a clear sequence of energy transfer.

Step 1: Resistance Heating

Electricity flows into the heating coils, which resist the current and convert the electrical energy directly into heat. This is the primary heat source.

Step 2: Conduction and Radiation

The hot coils transfer their thermal energy to the walls of the muffle chamber through a combination of direct contact (conduction) and thermal radiation.

Step 3: Uniform Chamber Heating

The refractory chamber walls heat up uniformly. This hot, enclosed surface then becomes the secondary heat source for the sample placed inside.

Step 4: Radiation and Convection

The sample is heated primarily through thermal radiation from all directions by the hot interior walls of the muffle. The air inside the chamber also heats up, creating convection currents that further contribute to a stable and uniform temperature distribution around the sample.

Understanding the Key Advantages and Trade-offs

The unique design of a muffle furnace creates distinct benefits and considerations.

Advantage: A Contaminant-Free Environment

This is the single most important advantage. Because the sample never makes contact with the electric heating elements or any byproducts of combustion (in older, fuel-fired designs), its purity is maintained. This is critical for chemical analysis, materials science, and quality control.

Advantage: Precise and Uniform Heating

The separation of the sample from the direct, intense heat of the coils, combined with heating from all sides via the chamber walls, results in exceptionally uniform temperature. The PID controller ensures this temperature is held with remarkable accuracy.

Trade-off: Operating Atmosphere

A standard muffle furnace operates with the air that is sealed inside the chamber. While perfect for many applications, processes requiring a specific gas (like nitrogen or argon) or a vacuum require more specialized and costly furnace designs.

Trade-off: Heating Rate

While muffle furnaces can heat rapidly, their primary design focus is on stability and uniformity, not sheer speed. The thermal mass of the refractory chamber and insulation means they take some time to heat up and cool down compared to other direct-heating methods.

Applying This to Your Application

Choosing to use a muffle furnace depends entirely on your process goals.

- If your primary focus is material purity and analytical accuracy: The muffle furnace is the ideal tool, as its isolated chamber guarantees a non-contaminating environment.

- If your primary focus is heat treatment requiring precise temperature profiles: The combination of a PID controller and uniform radiative heating makes the muffle furnace superior for tasks like annealing, tempering, and ashing.

- If your primary focus is high-volume, rapid melting: You may need to evaluate other furnace types, such as an induction furnace, which is designed for speed over the controlled environment of a muffle.

By understanding the core principle of isolated heating, you can confidently leverage the muffle furnace for any application that demands the highest levels of control and purity.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Heating Elements | Generate heat via electrical resistance (Joule heating) | High-temperature capability |

| Muffle Chamber | Isolates sample from heating elements | Prevents contamination, ensures purity |

| Insulation | Encases chamber to minimize heat loss | Energy efficient, safe exterior |

| PID Controller | Precisely regulates temperature based on thermocouple feedback | Exceptional stability and accuracy |

Ready to achieve precise, contamination-free heating in your lab?

KINTEK specializes in high-performance muffle furnaces designed for applications requiring the utmost accuracy and material purity, such as annealing, ashing, and quality control testing. Our equipment ensures uniform temperature distribution and reliable results for your laboratory.

Contact our experts today to find the perfect muffle furnace for your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a muffle furnace and an oven? Choose the Right High-Temperature Tool

- What is the main function of a muffle furnace? Achieve Pure, High-Temperature Processing

- What is dry ashing? A Reliable Method for Analyzing Inorganic Composition

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control