At its core, uniaxial and isostatic pressing are two distinct methods for compacting powder into a solid form before final sintering. Uniaxial pressing applies force along a single vertical axis, much like a piston in a cylinder. In contrast, isostatic pressing applies equal pressure from all directions simultaneously, using a fluid as the pressure-transmitting medium.

The fundamental choice between these methods is not about which is superior overall, but which is correct for your specific goal. Uniaxial pressing is built for speed and simplicity with basic shapes, while isostatic pressing is designed for complex geometries and superior material uniformity.

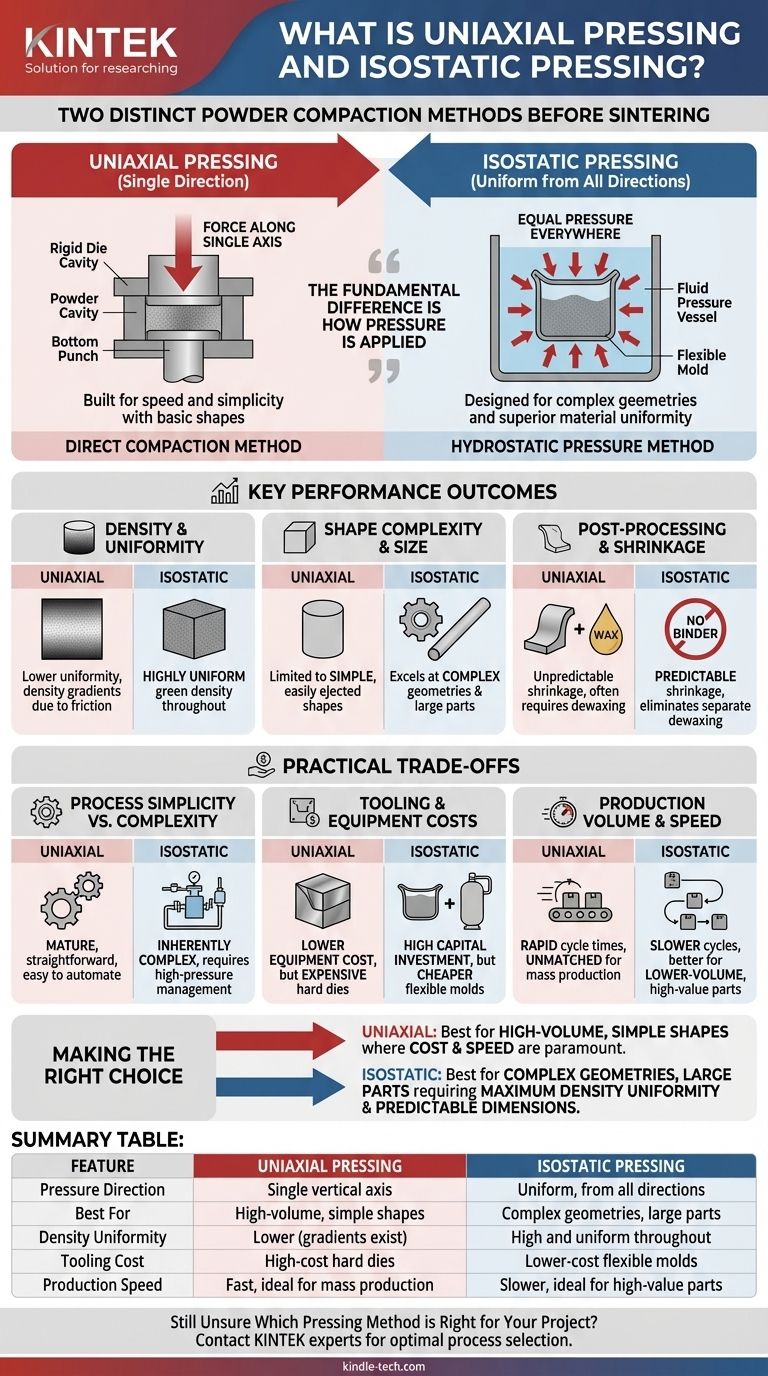

The Fundamental Difference: How Pressure is Applied

The way force is transmitted to the powder dictates the final properties of the compacted part. This is the most critical concept to understand when comparing these two processes.

Uniaxial Pressing: Force in a Single Direction

Uniaxial pressing is a direct compaction method. Powder is placed in a rigid die cavity, and one or more punches compress the powder along a single axis.

This mechanical simplicity makes it a fast, repeatable, and cost-effective process for high-volume manufacturing.

Isostatic Pressing: Uniform Pressure from All Directions

Isostatic pressing places the powder in a flexible, sealed mold which is then submerged in a fluid within a pressure vessel. As the fluid is pressurized, it exerts uniform, equal force on every surface of the mold.

This approach, known as hydrostatic pressure, eliminates many of the limitations inherent in single-axis compaction.

Comparing Key Performance Outcomes

The difference in pressure application leads to significant variations in the density, shape capability, and final quality of the "green" (unsintered) part.

Density and Uniformity

With uniaxial pressing, friction between the powder and the die walls causes density gradients. The part will be densest near the punches and less dense in the middle, a problem that worsens with taller parts.

Isostatic pressing overcomes this entirely. By applying pressure evenly from all directions, it produces a highly uniform green density throughout the entire part, regardless of its size or aspect ratio.

Shape Complexity and Size

Uniaxial pressing is limited to shapes that can be easily ejected from a rigid die, restricting its use for complex geometries or parts with undercuts.

Isostatic pressing excels here. Since the tooling is flexible, it can produce highly complex and intricate shapes, as well as very large components or long, thin rods that are impossible with conventional methods.

Post-Processing and Shrinkage

The uniform density from isostatic pressing results in more predictable and even shrinkage during the final sintering phase, reducing the risk of warping or distortion.

Furthermore, isostatic pressing often does not require the wax binders common in uniaxial pressing, which eliminates the need for a separate dewaxing operation, simplifying the overall workflow.

Understanding the Practical Trade-offs

Choosing a process involves balancing performance requirements with operational costs and complexity.

Process Simplicity vs. Complexity

Uniaxial pressing is a mature, straightforward mechanical process that is relatively easy to automate and operate at high speeds.

Isostatic pressing is inherently more complex, requiring the management of high-pressure fluid systems and more involved loading and unloading cycles.

Tooling and Equipment Costs

This is a point of frequent confusion. Uniaxial pressing requires a lower initial investment for the press itself, but the hard steel dies for each part design are often expensive to machine and maintain.

Isostatic pressing demands a very high capital investment for the high-pressure vessel. However, the flexible molds for individual part designs are typically much cheaper and faster to produce than hard tooling, offering greater flexibility for prototyping or diverse product lines.

Production Volume and Speed

For mass production of simple, standardized parts, the rapid cycle times of uniaxial pressing are unmatched.

Isostatic pressing cycles are generally slower due to the time needed to pressurize and depressurize the system, making it better suited for lower-volume, higher-value components.

Making the Right Choice for Your Application

Your final decision should be guided by the geometry of your part and the required material properties.

- If your primary focus is high-volume production of simple shapes (like pucks, bushings, or tablets) where cost and speed are paramount: Uniaxial pressing is the clear and logical choice.

- If your primary focus is creating complex geometries, large parts, or components requiring maximum density uniformity and predictable final dimensions: Isostatic pressing provides capabilities that are simply unattainable with uniaxial methods.

Ultimately, understanding how pressure shapes your material is the key to aligning your manufacturing process with your engineering goals.

Summary Table:

| Feature | Uniaxial Pressing | Isostatic Pressing |

|---|---|---|

| Pressure Direction | Single vertical axis | Uniform, from all directions |

| Best For | High-volume, simple shapes | Complex geometries, large parts |

| Density Uniformity | Lower (gradients exist) | High and uniform throughout |

| Tooling Cost | High-cost hard dies | Lower-cost flexible molds |

| Production Speed | Fast, ideal for mass production | Slower, ideal for high-value parts |

Still Unsure Which Pressing Method is Right for Your Project?

At KINTEK, we specialize in lab equipment and consumables, helping you navigate the complexities of powder compaction. Our experts can help you determine the optimal process—whether it's high-speed uniaxial pressing or high-uniformity isostatic pressing—to achieve your material and geometric goals.

Let's discuss your specific application and find the perfect solution for your laboratory needs.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What advantages does Cold Isostatic Pressing (CIP) offer for nickel-alumina composites? Enhance Density & Strength

- What is the difference between hot isostatic pressing and cold isostatic pressing? A Guide to Forming vs. Densification

- What role does an industrial-grade high-pressure manual screw pump play in an HHIP system? Achieve Precise Densification

- What role does an industrial-grade omnidirectional press play in the preparation of ultra-fine grained VT6 titanium?

- What role does Isostatic Pressing play in SiC production? Ensure Precision for Large-Scale Ceramic Heat Exchangers

- Why is semi-isostatic pressing used for ceramics? Unlock Uniform Density and Superior Precision

- What are the two types of presses? CIP vs. HIP for Advanced Materials Manufacturing

- What is the difference between wet bag and dry bag CIP? Choose the Right Process for Your Production Needs