In manufacturing and materials science, uniaxial pressing pressure is the force applied along a single vertical axis to compact a powder into a solid shape. This pressure, typically measured in megapascals (MPa) or pounds per square inch (psi), is the fundamental parameter used to transform loose particles into a cohesive object with initial strength, known as a "green body."

Uniaxial pressing is a rapid and economical method for forming parts from powders, but its defining characteristic—applying force from one direction—creates unavoidable density gradients. Understanding and managing these pressure-induced variations is the central challenge to achieving a strong, reliable final product.

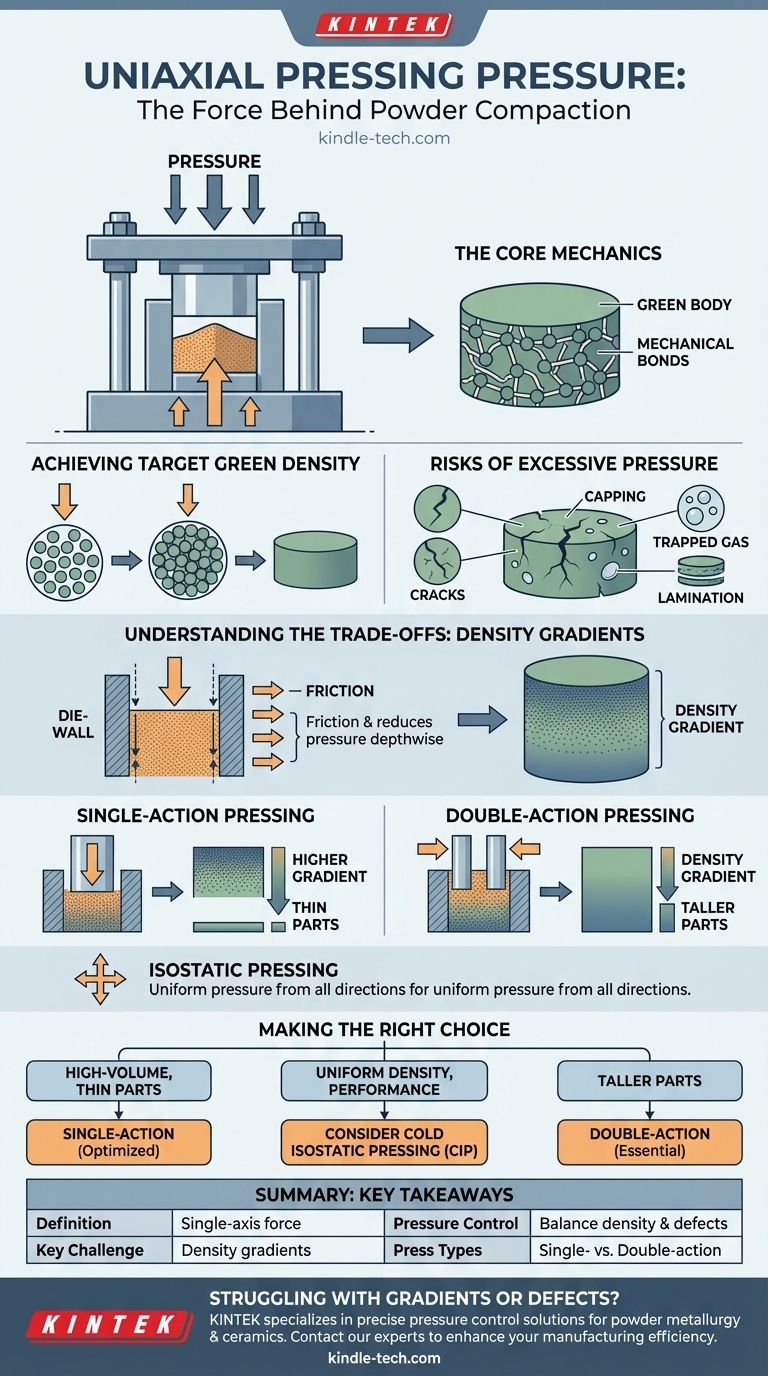

How Uniaxial Pressing Works: The Core Mechanics

Uniaxial pressing, sometimes called die pressing, is a cornerstone of powder metallurgy and ceramics production due to its speed and suitability for automation.

The Setup: Die, Punch, and Powder

The process begins by loading a precise amount of powder into a rigid cavity called a die. One or more punches then move vertically into the die, compressing the powder. The applied force divided by the cross-sectional area of the punch face gives the nominal uniaxial pressing pressure.

The Result: The "Green Body"

This compaction process forces the powder particles into close contact, reducing the voids between them and creating mechanical bonds. The resulting object is a green body or compact. It has enough strength to be handled but is still porous and requires a subsequent heating process (sintering) to achieve its final density and strength.

The Critical Role of Pressure in Part Formation

The amount of pressure applied is not arbitrary; it is a carefully controlled variable that directly dictates the quality of the green body.

Achieving Target Green Density

The primary goal of applying pressure is to increase the material's density. Higher pressure forces particles closer together, reducing porosity and increasing the green density of the compact. This is critical because a higher green density generally leads to less shrinkage and better mechanical properties in the final sintered part.

The Risks of Excessive Pressure

Simply maximizing pressure is not the solution and often creates severe defects. Too much pressure can trap air within the powder, leading to cracks upon ejection. It can also cause lamination (fractures parallel to the pressing direction) or capping (the top of the compact breaking off) due to internal stresses.

Understanding the Trade-offs: The Problem of Density Gradients

The greatest limitation of uniaxial pressing is its inability to create a perfectly uniform part. This is an inherent consequence of applying force along a single axis.

Die-Wall Friction: The Primary Culprit

As the punch transmits force through the powder, friction occurs between the particles and against the stationary die wall. This friction causes the pressure to diminish with depth. The result is a density gradient, where the areas of the compact nearest the moving punch are densest, and the area in the middle or furthest from the punch is the least dense.

Single-Action vs. Double-Action Pressing

To combat density gradients, presses can use different configurations:

- Single-Action Pressing: Only one punch (typically the top one) moves. This is the simplest method but creates the most severe density gradients, making it suitable only for thin, simple parts.

- Double-Action Pressing: Both a top and bottom punch move toward the center. This compresses the powder from both ends, significantly reducing the density gradient and allowing for the production of taller or more complex parts.

Uniaxial vs. Isostatic Pressing: A Key Distinction

It is crucial to distinguish uniaxial pressing from isostatic pressing. In isostatic pressing, pressure is applied uniformly from all directions via a fluid medium. This eliminates die-wall friction and produces a green body with extremely uniform density, but the process is significantly slower and more costly than uniaxial pressing.

Making the Right Choice for Your Goal

Selecting and controlling uniaxial pressing pressure is a balance between achieving sufficient density and avoiding defects. Your production goals will determine your approach.

- If your primary focus is high-volume production of simple, thin parts: Single-action uniaxial pressing is the most cost-effective method, but pressure must be carefully optimized to prevent capping.

- If your primary focus is uniform density for high-performance parts: The inherent density gradients of uniaxial pressing are a major liability; consider Cold Isostatic Pressing (CIP) as an alternative.

- If your primary focus is producing taller parts (e.g., bushings or gears): Double-action uniaxial pressing is essential to minimize density variations between the top, middle, and bottom of the component.

Mastering uniaxial pressing is less about maximizing force and more about controlling the pressure distribution throughout the part.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Definition | Force applied along a single axis to compact powder into a solid shape (green body). |

| Key Challenge | Inherent density gradients due to die-wall friction, leading to uneven part density. |

| Pressure Control | Balancing higher green density with the risk of defects like lamination and capping. |

| Press Types | Single-action (for thin parts) vs. double-action (for taller parts) to reduce density variations. |

Struggling with density gradients or part defects in your powder compaction process? KINTEK specializes in lab equipment and consumables, providing solutions for precise pressure control in powder metallurgy and ceramics. Our expertise helps you optimize uniaxial pressing for stronger, more reliable parts. Contact our experts today to discuss how we can enhance your manufacturing efficiency and product quality.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the Significance of Using a Laboratory Hydraulic Press for Green Compact Pressing? Optimize CNT Composites.

- In which stage of all-solid-state sodium-sulfur battery assembly is a laboratory hydraulic press used? Expert Guide

- Why is a precision laboratory hydraulic press required for manufacturing molybdenum target green bodies?

- What is the application of laboratory hydraulic presses in microalgae pelletization? Enhance Biomass Density

- How is a uniaxial hydraulic press utilized in the formation of solid-state electrolyte pellets? Boost Ionic Conductivity

- Is hydraulic fluid environmentally safe? Discover the Truth About Eco-Friendly Alternatives

- What will you do to reduce prevent excessive heating of oil in a hydraulic system? A Guide to Boosting Efficiency & Reliability

- Importance of Vacuum Infusion or Hydraulic Press in Bio-Based Composites? Unlock Superior Strength and Precision