In short, Vacuum Arc Melting (VAM) is a process that uses a high-current electric arc to melt metals and alloys inside a vacuum-sealed chamber. While VAM is a distinct process, the underlying goal—producing extremely pure, high-performance metals—is shared with a similar method, Vacuum Induction Melting (VIM), which uses electromagnetic induction instead of an arc. Both processes are essential for creating materials that cannot be produced in open air due to their high reactivity with oxygen and nitrogen.

The fundamental purpose of melting metals in a vacuum is to achieve superior purity and precise chemical control. By removing atmospheric gases, the process prevents contamination and eliminates unwanted impurities, which is critical for manufacturing high-performance alloys.

The Purpose of Melting in a Vacuum

The primary driver for moving the melting process into a vacuum is to control the material's environment. This control solves several critical manufacturing challenges.

Avoiding Atmospheric Contamination

Many advanced alloys, particularly those based on nickel, cobalt, or titanium, have a strong affinity for oxygen and nitrogen. Melting these materials in open air would introduce oxides and nitrides, creating brittle impurities that severely degrade the final product's mechanical properties.

Removing Undesirable Elements

A vacuum environment effectively removes impurities. Low-melting-point volatile metals and dissolved gases (like hydrogen) are pulled out of the molten metal, a process known as outgassing. This purifies the alloy to a degree not possible with conventional methods.

Enabling Precise Alloy Control

The clean environment allows for the precise control of an alloy's chemical composition. Elements that are highly reactive, such as aluminum and titanium, can be added with minimal loss. This enables the creation of "superalloys" with specific, repeatable properties for demanding applications.

The Vacuum Induction Melting (VIM) Process Explained

While your question was about arc melting, the most common process for this purpose is Vacuum Induction Melting. The principles of environmental control are identical.

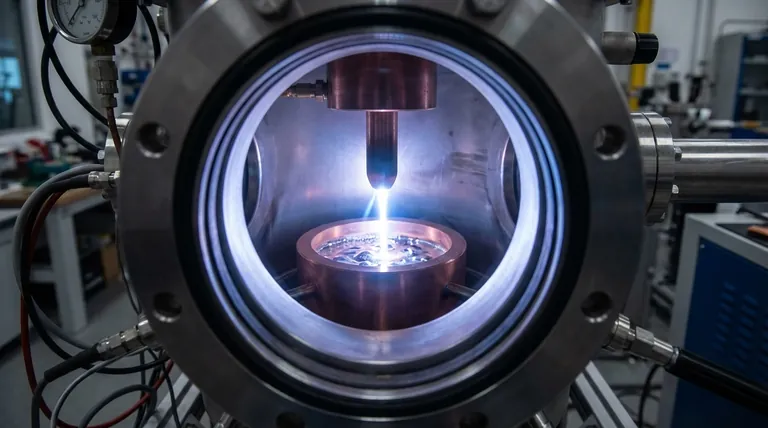

The Furnace and Core Principle

The VIM process takes place in an airtight, water-cooled steel chamber. Inside this chamber sits a crucible, typically lined with a refractory material, which holds the raw metal charge. An induction coil is wrapped around the crucible but does not touch it.

When a high-frequency alternating current is passed through the coil, it generates a powerful, fluctuating magnetic field. This field induces strong electrical eddy currents within the metal itself. The metal's natural resistance to these currents generates intense heat, causing it to melt from the inside out.

The Melting and Refining Stages

First, the raw metal is loaded into the crucible, and the chamber is sealed. Powerful pumps create a deep vacuum, removing the air.

As power is sent to the induction coil, the metal begins to melt. The electromagnetic field also creates a natural stirring action in the molten pool, which helps ensure a uniform temperature and chemical composition.

Once the metal is fully molten, the process enters a refining period. The combination of high temperature and vacuum allows impurities and dissolved gases to bubble out and be removed by the vacuum pumps. At this stage, final alloy additions can be made with high precision.

The Pouring Stage

After refining, the molten metal is poured into molds to create ingots or castings. This is also done under vacuum or in an inert gas atmosphere to prevent any re-contamination of the pure, molten alloy.

Understanding the Trade-offs: Arc vs. Induction

Both VAM and VIM achieve similar goals but use different heating methods, which makes them suitable for slightly different applications.

Vacuum Arc Melting (VAM)

In VAM, the heat source is a sustained electric arc. Typically, a solid electrode of the starting material is slowly melted by an arc struck between it and a shallow, water-cooled copper crucible. As the electrode melts, it drips down and solidifies, building up a pure ingot. VAM is often used as a secondary refining step for materials already melted in a VIM furnace.

Vacuum Induction Melting (VIM)

As described, VIM uses a contactless electromagnetic field to generate heat directly within the metal. Because the heat source is separate from the material, it offers excellent control over temperature and chemistry, making it a primary melting method for a wide spectrum of iron, nickel, and cobalt-based superalloys.

Making the Right Choice for Your Goal

Selecting the right vacuum process depends entirely on the material requirements and the desired level of purity.

- If your primary focus is producing initial batches of high-purity superalloys from raw materials: Vacuum Induction Melting (VIM) is the industry standard for its excellent chemical and temperature control.

- If your primary focus is further refining an existing ingot to achieve maximum cleanliness and a specific crystal structure: Vacuum Arc Melting (VAM) is often the preferred secondary step to remove inclusions and control solidification.

Ultimately, vacuum processing is the enabling technology behind the world's most advanced and reliable metal components.

Summary Table:

| Process | Heating Method | Primary Use | Key Advantage |

|---|---|---|---|

| Vacuum Arc Melting (VAM) | Electric arc | Secondary refining, crystal structure control | Removes inclusions, ideal for reactive metals |

| Vacuum Induction Melting (VIM) | Electromagnetic induction | Primary melting of superalloys | Excellent temperature and chemistry control |

Need high-purity metals for your advanced applications? KINTEK specializes in lab equipment and consumables for vacuum melting processes, helping you achieve superior material purity and performance. Contact us today to discuss how our solutions can meet your laboratory's specific needs!

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the capacity of an induction furnace? Find the Right Size for Your Lab or Foundry

- What metals work with induction heating? Understanding Magnetic & Electrical Properties for Efficient Heating

- What is the concept of an induction furnace? Unlock Fast, Clean, and Efficient Metal Melting

- Does induction heating work on non-ferrous metals? A Guide to Efficiently Heating Copper, Aluminum & More

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- What factors influence the quality of the sintered induction furnace lining? Optimize Durability and Performance

- What is vacuum induction melting used for? Creating Ultra-Pure Metals for Demanding Industries

- What is the difference between coreless and cored induction furnace? Choose the Right Tool for Your Foundry