In the context of nanotechnology, vacuum deposition is a family of processes used to apply exceptionally thin and uniform layers of material onto a surface. Executed inside a high-vacuum chamber, this method allows for the controlled placement of materials one atom or molecule at a time, making it a cornerstone for fabricating nanostructures like nanowires, nanosponges, and advanced coatings.

The essential value of vacuum deposition in nanotechnology is not merely coating a surface, but achieving atomic-level control over a material's properties. By building films layer-by-layer in a pristine vacuum, we can engineer materials with characteristics like enhanced durability or transparency that are impossible to achieve with bulk materials.

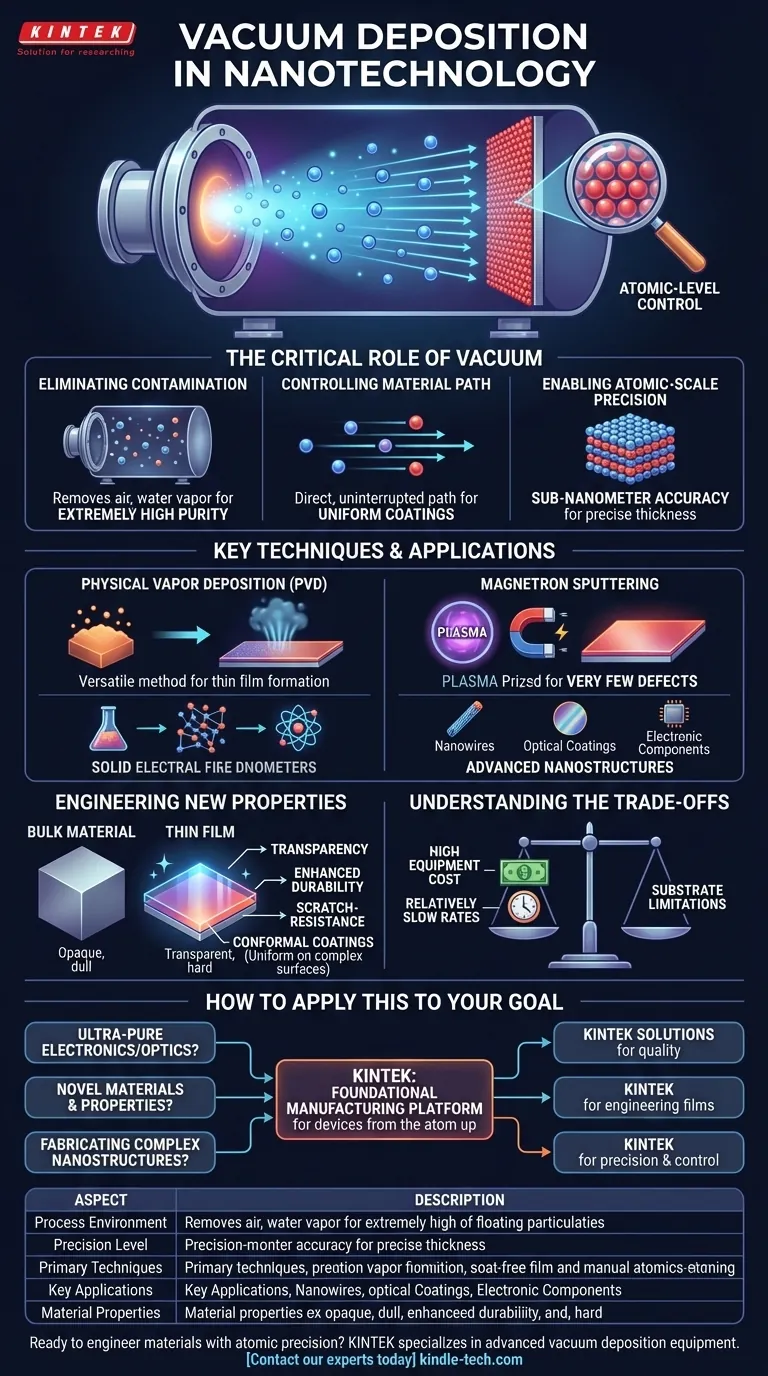

Why a Vacuum is the Critical Component

The process is defined by its environment. Operating inside a vacuum is not an incidental detail; it is the key factor that enables the precision required for nanotechnology.

Eliminating Contamination

A vacuum removes air, water vapor, and other particles that would otherwise interfere with the process. This ensures that the deposited film is of extremely high purity, which is critical for the performance of nano-electronics and optical components.

Controlling Material Path

In the near-total absence of air, atoms or molecules vaporized from a source material travel in a straight, uninterrupted line to the target surface (the substrate). This direct path is essential for creating uniform, predictable coatings.

Enabling Atomic-Scale Precision

This controlled environment makes it possible to deposit layers that are just a single atom thick. This gives engineers subnanometer-level accuracy over the final thickness and structure of the film.

Key Techniques and Applications

While "vacuum deposition" is a broad term, it includes several specific methods. Physical Vapor Deposition (PVD) is one of the most common families of techniques used in nanotechnology.

Physical Vapor Deposition (PVD)

PVD encompasses methods where a solid material is converted into a vapor, transported through the vacuum, and condensed onto a substrate as a thin film. This is a highly versatile technique for a wide range of materials.

Magnetron Sputtering

A prominent PVD method, magnetron sputtering, is prized for its ability to create films with very few defects. It is a go-to technique for demanding applications in thin-film nanotechnology where material quality is paramount.

Fabricating Advanced Nanostructures

These techniques are not limited to flat coatings. They provide the control needed to grow complex structures like nanowires and nanobelts or to assemble nanoparticles into functional coatings with enhanced properties.

The Power of Engineering New Properties

The true significance of thin-film deposition in nanotechnology is its ability to create materials with novel characteristics that differ from the source material.

Beyond Bulk Materials

A material's properties can change dramatically when it is structured as an ultra-thin film. A material that is opaque in bulk form might become transparent, or a soft material can become incredibly hard.

Examples of Enhanced Functionality

This process is used to create specialized coatings that provide enhanced scratch-resistance, durability, and specific optical properties like anti-reflection.

Unlocking Conformal Coatings

Vacuum deposition can produce highly conformal layers, meaning the film's thickness is perfectly uniform, even over complex, non-flat surfaces. This is vital for coating intricate nanostructures.

Understanding the Trade-offs

While powerful, vacuum deposition is a specialized process with practical considerations that make it unsuitable for every application.

High Equipment Cost

Vacuum chambers, high-power sources, and monitoring equipment are complex and expensive. The initial capital investment can be significant.

Relatively Slow Deposition Rates

Building a film atom by atom is precise but can be much slower than other coating methods like painting or electroplating. This makes it ideal for high-value, high-performance components rather than bulk coating.

Substrate Limitations

The process requires a substrate material that can withstand high-vacuum conditions and, in some cases, elevated temperatures without degrading or releasing gases.

How to Apply This to Your Goal

Choosing the right approach depends entirely on the intended outcome.

- If your primary focus is creating ultra-pure, defect-free electronic or optical components: Vacuum deposition, especially magnetron sputtering, is the industry standard for achieving this level of quality.

- If your primary focus is developing novel materials with unique surface properties: The ability of vacuum deposition to engineer thin films with engineered characteristics is its key advantage.

- If your primary focus is fabricating complex nanostructures like nanowires or sensors: PVD techniques provide the directional control and precision needed to grow these intricate forms reliably.

Ultimately, vacuum deposition is the foundational manufacturing platform that gives us the control necessary to build functional devices and materials from the atom up.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Environment | High-vacuum chamber for contamination-free deposition |

| Precision Level | Subnanometer accuracy, single-atom layer control |

| Primary Techniques | Physical Vapor Deposition (PVD), Magnetron Sputtering |

| Key Applications | Nanowires, optical coatings, electronic components |

| Material Properties | Enhanced durability, transparency, scratch-resistance |

Ready to engineer materials with atomic precision? KINTEK specializes in advanced vacuum deposition equipment and consumables for nanotechnology applications. Whether you're developing next-generation electronic components, optical coatings, or complex nanostructures, our solutions provide the purity and control your research demands. Contact our experts today to discuss how we can support your lab's nanotechnology innovation with reliable, high-performance equipment.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process