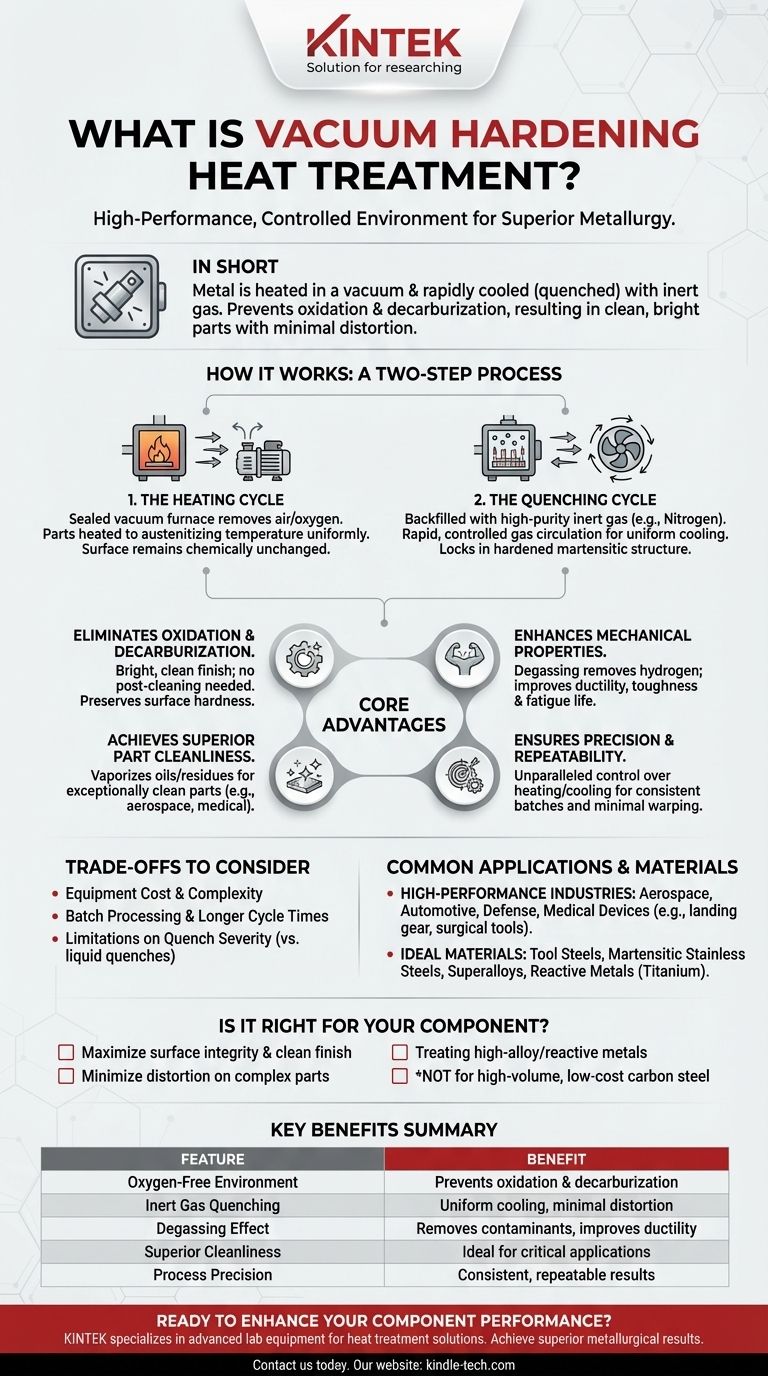

In short, vacuum hardening is a high-performance heat treatment process where metal is heated in a vacuum and then rapidly cooled (quenched) with an inert gas. This controlled, oxygen-free environment prevents unwanted surface reactions like oxidation and decarburization, resulting in a clean, bright part with superior mechanical properties and minimal distortion.

The critical advantage of vacuum hardening is not the heat itself, but the environment in which it's applied. By removing air and other reactive gases, the process protects the material's surface integrity and chemical composition, yielding components that are stronger, cleaner, and more dimensionally stable than those treated in traditional atmospheres.

How Vacuum Hardening Works: A Two-Step Process

At its core, vacuum hardening is a carefully controlled sequence of heating and cooling designed to alter a material's microstructure to achieve desired hardness and strength. The process is defined by two critical stages.

The Heating Cycle: Protecting the Material

First, the components are loaded into a sealed vacuum furnace. Air is pumped out to create a near-vacuum, eliminating oxygen and other gases that could react with the hot metal surface.

The parts are then heated to a specific austenitizing temperature, which varies depending on the alloy. The vacuum ensures this heating is uniform and that the material's surface remains chemically unchanged.

The Quenching Cycle: Locking in Hardness

Once the material is at the correct temperature, it must be cooled rapidly to lock in the hardened martensitic structure. This is accomplished by backfilling the furnace with a high-purity inert gas, such as nitrogen or argon.

Powerful fans circulate this gas at high pressure, quickly and evenly removing heat from the components. The pressure and velocity of the gas can be precisely controlled to manage the cooling rate and minimize thermal shock or distortion.

The Core Advantages of a Vacuum Environment

Choosing to perform hardening in a vacuum is a deliberate engineering decision. The benefits stem directly from eliminating the atmosphere's influence on the metal at high temperatures.

Eliminating Oxidation and Decarburization

This is the most significant benefit. With no oxygen present, the part's surface cannot oxidize, resulting in a bright, clean finish that often requires no subsequent cleaning or machining. It also prevents decarburization—the loss of carbon from the surface of steel—which preserves the material's designed hardness and wear resistance.

Enhancing Mechanical Properties

The vacuum environment actively pulls contaminants, such as hydrogen and other trapped gases, out of the material. This degassing process reduces the risk of hydrogen embrittlement, enhancing the component's overall ductility, toughness, and fatigue life.

Achieving Superior Part Cleanliness

The high heat and vacuum combination vaporizes and removes surface contaminants like oils and residues from prior manufacturing steps. This results in an exceptionally clean part, which is critical for applications in industries like aerospace and medical devices.

Ensuring Precision and Repeatability

Vacuum furnaces offer unparalleled control over heating and cooling cycles. This precision leads to highly consistent and repeatable results from batch to batch, while the uniform gas quenching minimizes the internal stresses that cause parts to warp or distort.

Understanding the Trade-offs

While powerful, vacuum hardening is not the universal solution for all applications. It is a specialized process with specific considerations.

Equipment Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to traditional atmospheric furnaces. They are complex machines that require specialized knowledge for operation and maintenance.

Batch Processing and Cycle Times

Vacuum hardening is inherently a batch process. The time required to pump down the chamber, run the thermal cycle, and cool the furnace can result in longer overall lead times compared to continuous, non-vacuum heat treatment methods.

Limitations on Quench Severity

While modern high-pressure gas quenching is extremely effective, it may not achieve the same extreme cooling rates as aggressive liquid quenches (e.g., water or certain oils). For some very thick-sectioned components made of lower-hardenability alloys, a liquid quench may still be necessary.

Common Applications and Materials

The unique benefits of vacuum hardening make it the preferred choice for components where performance, reliability, and precision are non-negotiable.

High-Performance Industries

Industries like aerospace, automotive, defense, and medical device manufacturing rely heavily on vacuum heat treatment. It is essential for critical components like landing gear, engine parts, high-performance tooling, and surgical instruments.

Ideal Material Candidates

This process is particularly effective for high-alloy materials. Common candidates include tool steels (for hot and cold work), martensitic stainless steels, superalloys (iron-nickel or cobalt-based), and reactive metals like titanium.

Is Vacuum Hardening Right for Your Component?

Making the right choice depends entirely on the specific requirements of your part and its application.

- If your primary focus is maximum surface integrity and a clean, bright finish: Vacuum hardening is the ideal choice, as it prevents oxidation and eliminates the need for post-treatment cleaning.

- If your primary focus is minimizing distortion on complex or thin-walled parts: The uniform heating and controlled gas quenching of a vacuum process offer superior dimensional stability.

- If your primary focus is treating high-alloy steels, superalloys, or reactive metals: The protective, inert environment of a vacuum furnace is often the only way to correctly process these sensitive materials.

- If your primary focus is high-volume, low-cost production of simple carbon steel parts: Traditional atmospheric or induction hardening may provide a more economical solution.

Ultimately, vacuum hardening delivers a superior metallurgical result by precisely controlling every variable of the heat treatment process.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Oxygen-Free Environment | Prevents surface oxidation and decarburization. |

| Inert Gas Quenching | Ensures uniform cooling with minimal distortion. |

| Degassing Effect | Removes contaminants, improving ductility and fatigue life. |

| Superior Part Cleanliness | Vaporizes surface oils and residues; ideal for aerospace and medical devices. |

| Process Precision | Delivers highly repeatable and consistent results batch after batch. |

Ready to enhance your component performance with precision vacuum hardening?

KINTEK specializes in advanced lab equipment and consumables for demanding laboratory needs. Our expertise in heat treatment solutions can help you achieve superior metallurgical results—ensuring your parts are stronger, cleaner, and more reliable.

Contact us today to discuss how our vacuum furnaces and consumables can meet your specific application requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vertical Laboratory Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing