To put it simply, vacuum nitriding is a highly controlled heat treatment process that uses a low-pressure (vacuum) environment to diffuse nitrogen into the surface of a steel or alloy part. This creates an extremely hard and wear-resistant surface layer, known as the case, without altering the core properties of the material. It is a modern evolution of traditional gas nitriding, designed for greater precision, speed, and quality.

The core advantage of vacuum nitriding isn't just about making parts harder; it's about achieving that hardness with exceptional uniformity and control, especially on components with complex shapes, making it a superior choice for high-performance applications.

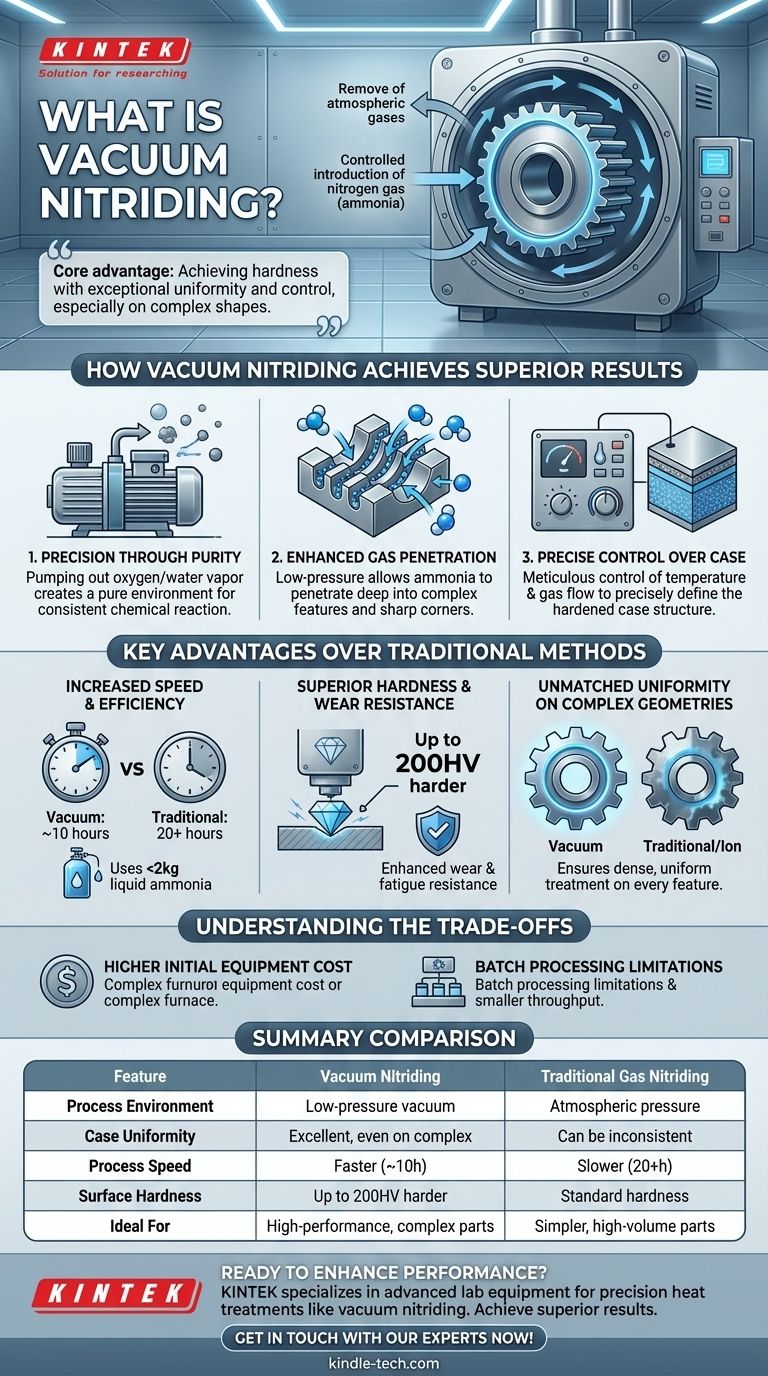

How Vacuum Nitriding Achieves Superior Results

Vacuum nitriding refines the traditional gas nitriding process by first removing the atmosphere from the furnace. This initial vacuum step is critical and provides several key benefits that lead to a higher quality outcome.

Precision Through Purity

By pumping out atmospheric gases like oxygen and water vapor, the process creates a pure environment. When the nitriding gas (typically ammonia) is introduced, it can react directly with the steel surface without interference from contaminants.

This leads to a more predictable and consistent chemical reaction, resulting in a cleaner surface and a more uniform hardened layer.

Enhanced Gas Penetration

The low-pressure environment allows the ammonia gas to penetrate deep into complex features. This is a significant advantage over other methods.

Vacuum nitriding ensures that sharp corners, small holes, deep slits, and dense surfaces are all treated evenly. This comprehensive coverage prevents weak spots and ensures consistent performance across the entire part.

Precise Control Over the Case Layer

The process allows for meticulous control over temperature and gas flow. This gives engineers the ability to precisely define the structure of the hardened case, including the thickness of the "white layer" (a compound layer at the very surface).

This level of control is essential for applications where brittleness must be avoided and specific fatigue or wear characteristics are required.

Key Advantages Over Traditional Methods

When compared directly to older methods like conventional gas or ion nitriding, the benefits of the vacuum process become clear and measurable.

Increased Speed and Efficiency

Vacuum nitriding can be significantly faster. For example, achieving a 0.3 mm hardened layer can take as little as 10 hours, compared to over 20 hours for traditional gas nitriding.

It is also far more efficient with resources, consuming less than 2kg of liquid ammonia for a typical cycle, whereas continuous gas nitriding can consume over 1kg per hour.

Superior Hardness and Wear Resistance

The resulting nitrided layer is demonstrably harder. Parts treated with vacuum nitriding at 530°C can be up to 200HV harder than those treated with gas nitriding at a similar temperature.

This increased hardness translates directly to enhanced resistance to wear, abrasion, and fatigue, extending the service life of the component.

Unmatched Uniformity on Complex Geometries

This is where vacuum nitriding truly excels. It provides better temperature uniformity and surface quality than even ion nitriding, especially on intricate parts.

The process ensures that every feature, no matter how small or difficult to reach, receives a dense, uniform treatment.

Understanding the Trade-offs

No process is perfect for every situation. While vacuum nitriding offers significant performance advantages, it's important to consider its limitations to make an informed decision.

Higher Initial Equipment Cost

Vacuum furnaces and their associated control systems are more complex and expensive than the equipment used for conventional atmospheric gas nitriding. This can translate to a higher per-piece cost, especially for simpler components.

Batch Processing Limitations

Vacuum nitriding is a batch process. While ideal for high-value components, it may not offer the same high-volume throughput as some large-scale, continuous gas nitriding operations. This makes it less suitable for low-cost, mass-produced parts where process speed is the primary driver.

Making the Right Choice for Your Goal

The decision to use vacuum nitriding should be based on the specific performance requirements of your component.

- If your primary focus is high-performance and complex geometries: Vacuum nitriding is the clear choice for its superior uniformity, hardness, and control on parts like precision gears, molds, and transmission components.

- If your primary focus is low-cost, high-volume production of simple parts: Traditional gas nitriding may be a more cost-effective solution where the absolute highest level of precision is not required.

- If your primary focus is maximizing speed and surface hardness: Vacuum nitriding provides a measurable advantage in both processing time and the quality of the final hardened case.

Ultimately, vacuum nitriding represents a shift from a bulk heat treatment to a precision surface engineering process for components that demand the highest reliability.

Summary Table:

| Feature | Vacuum Nitriding | Traditional Gas Nitriding |

|---|---|---|

| Process Environment | Low-pressure vacuum | Atmospheric pressure |

| Case Uniformity | Excellent, even on complex shapes | Can be inconsistent |

| Process Speed | Faster (e.g., ~10 hours for 0.3mm case) | Slower (e.g., 20+ hours for 0.3mm case) |

| Surface Hardness | Up to 200HV harder | Standard hardness |

| Ideal For | High-performance, complex components | Simpler, high-volume parts |

Ready to enhance the performance and lifespan of your critical components?

KINTEK specializes in advanced lab equipment and consumables, including solutions for precision heat treatments like vacuum nitriding. Our expertise helps laboratories and manufacturers achieve superior surface hardness, wear resistance, and unparalleled uniformity on complex parts.

Contact us today to discuss how our solutions can meet your specific laboratory needs and drive your projects forward.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space