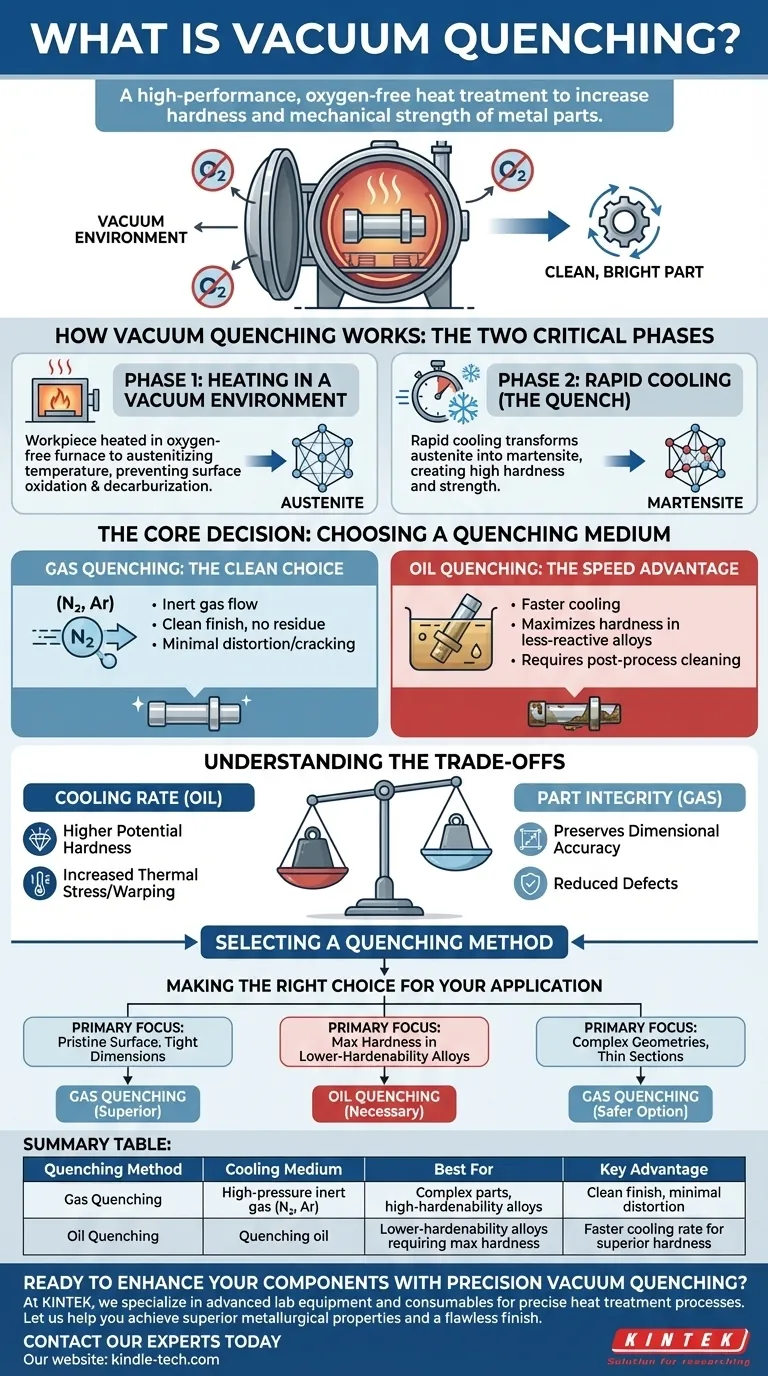

Vacuum quenching is a high-performance heat treatment process used to increase the hardness and mechanical strength of metal parts. It involves heating a material to a specific temperature within a vacuum furnace, holding it there, and then cooling it rapidly with a controlled medium to lock in a desirable metallurgical structure. This entire process is conducted without oxygen, which prevents surface oxidation and results in a clean, bright part.

At its core, vacuum quenching is about achieving two goals simultaneously: transforming a metal’s internal structure for maximum hardness and doing so in a pristine environment that prevents surface defects like scale and discoloration. The critical decision in this process is choosing the right cooling medium—gas or oil—which dictates the balance between cooling speed and part integrity.

How Vacuum Quenching Works: The Two Critical Phases

The process can be broken down into two distinct and equally important stages: heating and quenching. The vacuum environment is the common thread that makes this technique so effective.

Phase 1: Heating in a Vacuum Environment

The first step involves placing the workpiece into a vacuum furnace. The furnace chamber is evacuated, removing oxygen and other reactive gases.

The part is then heated to its austenitizing temperature, a specific point where its crystalline structure transforms into a phase known as austenite.

This controlled, oxygen-free atmosphere is crucial because it completely prevents oxidation and decarburization (the loss of carbon from the surface), which are common problems in traditional atmosphere-based furnaces.

Phase 2: Rapid Cooling (The Quench)

Once the material is fully transformed into austenite, it must be cooled rapidly. This rapid cooling, or "quench," does not allow the austenite structure to revert to its softer, pre-heated state.

Instead, it forces a transformation into martensite, a very hard, brittle crystalline structure. It is this martensitic structure that gives the quenched part its high hardness and strength.

The speed of the quench is critical and is determined by the cooling medium used.

The Core Decision: Choosing a Quenching Medium

The choice of cooling medium is the most significant variable in vacuum quenching and directly impacts the final properties of the component.

Gas Quenching: The Clean Choice

In vacuum gas quenching, the heated part is cooled by introducing a high-pressure flow of inert gas, typically nitrogen or argon, into the furnace.

This method is exceptionally clean, as it leaves no residue on the part's surface. The parts emerge from the furnace bright, shiny, and ready for use without any need for post-process cleaning.

Gas quenching offers a more uniform and less severe cool-down, which significantly reduces the risk of part distortion or cracking, especially in components with complex geometries or thin sections.

Oil Quenching: The Speed Advantage

For some steel alloys with lower hardenability, gas quenching is not fast enough to achieve the full martensitic transformation. These materials require vacuum oil quenching.

In this process, the heated part is moved from the vacuum heating chamber to an integrated, sealed chamber filled with quenching oil.

Oil extracts heat much faster than gas, ensuring that even less-reactive alloys achieve maximum hardness. The trade-off is that the part must be thoroughly cleaned after treatment to remove oil residue.

Understanding the Trade-offs

Selecting a quenching method requires balancing competing priorities. Your choice will always involve a series of engineering trade-offs.

Cooling Rate vs. Part Integrity

A faster quench (oil) delivers higher potential hardness but also induces greater thermal stress. This increases the risk of warping, distortion, and even micro-cracks in the workpiece.

A slower, more controlled quench (gas) is gentler on the part, preserving dimensional accuracy and reducing the likelihood of defects.

Cleanliness vs. Process Complexity

Gas quenching is a single-step, clean process. Parts are finished when they exit the furnace.

Oil quenching is inherently messy and requires an additional, often time-consuming, cleaning stage. This adds operational complexity and cost to the overall manufacturing workflow.

Material Compatibility

The choice is often dictated by the material itself. High-hardenability alloys like certain tool steels can be successfully hardened with gas.

However, many common structural and bearing steels require the more aggressive cooling rate of oil to meet their specified hardness requirements.

Making the Right Choice for Your Application

To choose the correct method, you must clearly define the most critical outcome for your component.

- If your primary focus is a pristine surface finish and tight dimensional stability: Gas quenching is the superior choice, as it eliminates the need for cleaning and minimizes distortion.

- If your primary focus is achieving maximum hardness in lower-hardenability alloys: Oil quenching is often necessary due to its faster and more aggressive cooling rate.

- If your project involves complex geometries, sharp corners, or thin cross-sections: Gas quenching provides a more controlled and uniform cooling process, making it the safer option to prevent defects.

By understanding these core principles, you can select the precise vacuum quenching method that meets both your material's metallurgical needs and your project's final quality standards.

Summary Table:

| Quenching Method | Cooling Medium | Best For | Key Advantage |

|---|---|---|---|

| Gas Quenching | High-pressure inert gas (N₂, Ar) | Complex parts, high-hardenability alloys | Clean finish, minimal distortion |

| Oil Quenching | Quenching oil | Lower-hardenability alloys requiring max hardness | Faster cooling rate for superior hardness |

Ready to enhance your components with precision vacuum quenching?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise heat treatment processes. Whether you need the clean, distortion-free results of gas quenching or the maximum hardness achieved with oil quenching, our solutions are tailored to meet your laboratory's specific material and quality standards.

Let us help you achieve superior metallurgical properties and a flawless finish. Contact our experts today to discuss your project requirements and discover the right vacuum quenching solution for your needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is heat treatment used for casting? Enhance Strength, Durability, and Performance

- What are the advantages of using a vacuum furnace with a flexible membrane? High-Precision Titanium Bonding Explained

- How does the co-sintering process improve bulk-type ASSBs? Optimize Interfaces with Advanced High-Temperature Furnaces

- What function does the vacuum environment serve during the densification of Ag-SnO2-Y2O3? Optimize Material Density

- What is the function of a vacuum oven in NRPE preparation? Enhance Purity and Battery Performance

- What gases are used in sintering? Choosing the Right Atmosphere for Your Material

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength

- What is the effect of vacuum on heat transfer? Mastering Thermal Control in Extreme Environments