Directly stated, the best materials for induction heating are ferromagnetic metals like iron and carbon steel. These materials are not only electrically conductive, which is a minimum requirement, but their magnetic properties dramatically increase the heating effect.

The effectiveness of a material for induction heating is determined by two key physical properties: its ability to carry induced electrical currents (eddy currents) and its magnetic response to the field (hysteresis). Ferromagnetic materials excel at both, making them heat far more rapidly and efficiently than other metals.

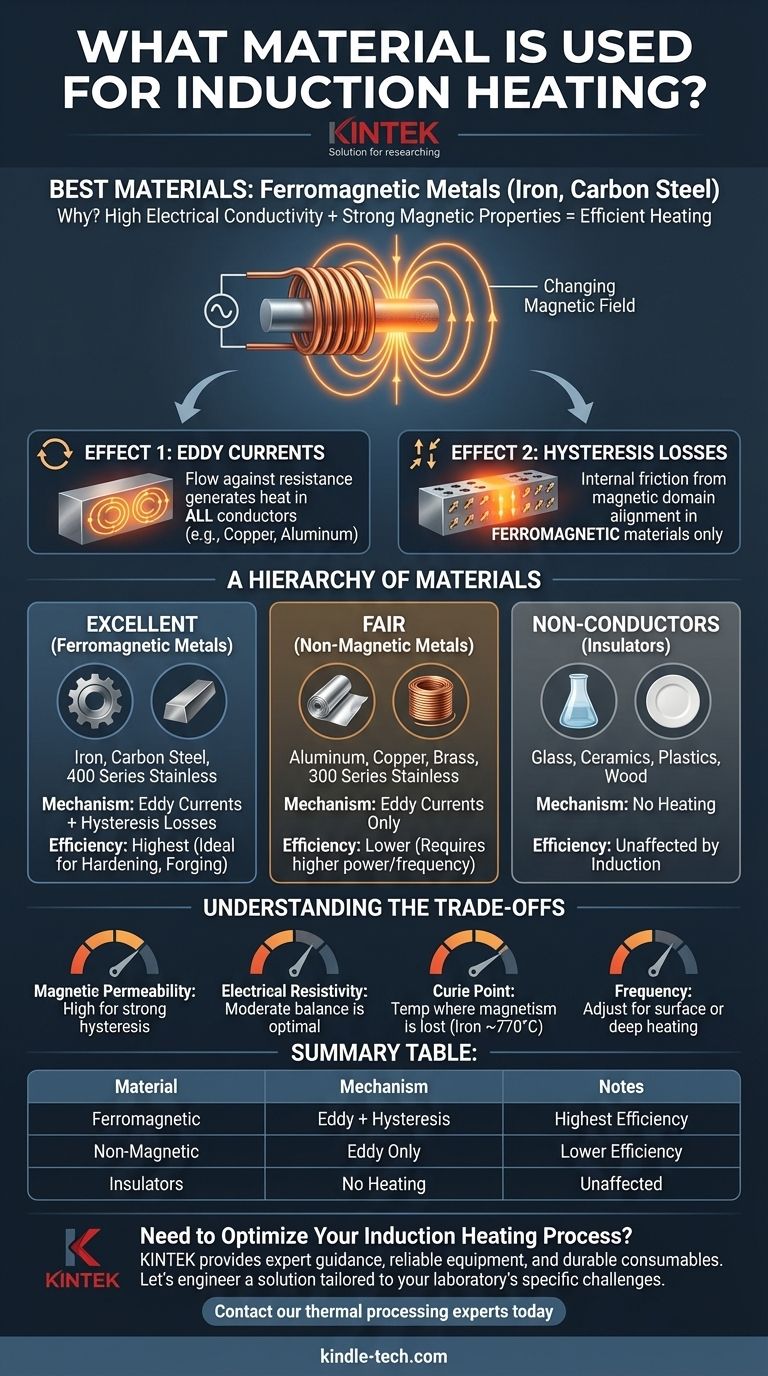

The Physics of Induction: Why Some Materials Heat and Others Don't

To choose the right material, you must first understand the mechanism. Induction heating is not about direct contact with a heat source; it's about generating heat within the material itself using a powerful, changing magnetic field.

The Role of a Changing Magnetic Field

An induction heater uses a coil, typically made of copper, through which a high-frequency alternating current (AC) is passed. This current generates a rapidly oscillating magnetic field around the coil. When you place a suitable material inside this field, two heating effects occur.

Effect 1: Eddy Currents

The fluctuating magnetic field induces small, circular electrical currents within the material, known as eddy currents. Every conductive material, including copper and aluminum, will experience this effect.

These currents flow against the material's natural electrical resistance, and this opposition generates heat. This is the same principle as the heating element in a toaster (Joule heating), but the currents are induced remotely.

Effect 2: Hysteresis Losses

This second effect is what separates excellent materials from merely adequate ones. It only occurs in ferromagnetic materials like iron, nickel, and cobalt.

These materials are composed of tiny magnetic regions called "domains." When exposed to the alternating magnetic field, these domains rapidly flip their orientation back and forth, trying to align with the field. This rapid flipping creates a kind of "internal friction," which generates a significant amount of heat.

A Hierarchy of Induction-Ready Materials

The efficiency of induction heating varies dramatically based on the material's properties.

Excellent Conductors: Ferromagnetic Metals

These materials benefit from both eddy currents and powerful hysteresis losses, making them ideal.

- Iron (Cast Iron, Wrought Iron)

- Carbon Steels

- Ferritic and Martensitic Stainless Steels (e.g., 400 series)

These are the go-to choices for industrial applications like hardening, forging, and brazing, as well as high-performance induction cookware.

Fair Conductors: Non-Magnetic Metals

These metals are conductive but not magnetic. They heat only through the eddy current effect, making the process less efficient and often requiring higher power or frequency.

- Aluminum

- Copper

- Brass

- Austenitic Stainless Steels (e.g., 304, 316 series)

To make cookware from these materials work on an induction stove, manufacturers bond a ferromagnetic steel plate to the bottom.

Non-Conductors: Insulators

These materials do not heat up at all in an induction field. They are neither electrically conductive (no eddy currents) nor magnetic (no hysteresis).

- Glass

- Ceramics

- Plastics

- Wood

This is why you can place a piece of paper between an induction cooktop and a steel pot, and the pot will heat while the paper remains unharmed.

Understanding the Trade-offs

Choosing a material isn't always straightforward. The interplay between different properties and operating conditions matters.

Magnetic Permeability vs. Resistivity

Magnetic permeability is the measure of a material's ability to support the formation of a magnetic field. Ferromagnetic materials have high permeability, which is essential for strong hysteresis heating.

Electrical resistivity is also crucial. While a material must be conductive, a very low resistance (like in pure copper) can make it harder to generate heat via eddy currents, as the currents flow too easily. A moderate level of resistance is often optimal. Iron and steel strike an excellent balance between these two properties.

The Impact of Temperature: The Curie Point

A critical factor for ferromagnetic materials is the Curie temperature. This is the temperature at which the material loses its magnetic properties.

For iron, this is approximately 770°C (1418°F). Once a piece of steel is heated past this point, the highly efficient hysteresis heating stops completely. Heating continues via eddy currents alone, but the rate of heating slows considerably.

The Role of Frequency

The frequency of the alternating current in the coil can be adjusted to optimize the process. Higher frequencies tend to concentrate heat on the surface of the material (known as the "skin effect"), which is ideal for surface hardening. Lower frequencies penetrate deeper, which is better for through-heating a large workpiece before forging.

Making the Right Choice for Your Goal

Your application determines which material properties are most important.

- If your primary focus is maximum heating efficiency (e.g., cookware, industrial hardening): Choose a ferromagnetic material like carbon steel or cast iron to leverage both hysteresis and eddy current heating.

- If your primary focus is heating non-magnetic metals (e.g., melting aluminum): You must rely solely on eddy currents, which may require higher power and a carefully selected frequency to be effective.

- If you need to hold a workpiece or shield a component from heat: Use an electrical and magnetic insulator like a high-temperature ceramic or glass.

By understanding the principles behind induction, you can move from simply picking a material to strategically engineering a highly effective thermal process.

Summary Table:

| Material Category | Key Examples | Heating Mechanism | Efficiency & Notes |

|---|---|---|---|

| Excellent (Ferromagnetic) | Iron, Carbon Steel, 400 Series Stainless Steel | Eddy Currents + Hysteresis Losses | Highest efficiency; ideal for hardening, forging, and cookware. |

| Fair (Non-Magnetic Metals) | Aluminum, Copper, 300 Series Stainless Steel | Eddy Currents Only | Lower efficiency; often requires higher power/frequency. |

| Non-Conductors (Insulators) | Glass, Ceramics, Plastics, Wood | No Heating | Unaffected by induction fields; useful for fixtures and shielding. |

Need to Optimize Your Induction Heating Process?

Choosing the right material is just the first step. KINTEK specializes in providing high-performance lab equipment and consumables to support your precise thermal processing needs. Whether you are developing new materials or optimizing an existing heating application, our expertise can help you achieve superior results.

We provide:

- Expert guidance on material selection and process parameters.

- Reliable equipment for consistent, repeatable heating.

- Durable consumables designed for high-temperature environments.

Let's engineer a solution tailored to your laboratory's specific challenges.

Contact our thermal processing experts today to discuss how we can enhance your efficiency and performance.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Infrared Heating Quantitative Flat Plate Press Mold

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Boron Nitride (BN) Ceramic Tube

People Also Ask

- What is the voltage limit in an induction furnace? It's a Tale of Two Power Systems

- What is the design of an induction melting furnace? Master Contactless, Efficient Metal Melting

- What is the melting process of an electric arc furnace? Unlock Efficient, High-Quality Steel Production

- What is the process of melting in an induction furnace? Harnessing Electromagnetic Power for Efficient Metal Melting

- What roles do VIM and VAR play in Alloy 718? Achieve Superior Purity and Structural Integrity

- What are the disadvantages of inductive heating? High Cost and Material Limitations Explained

- How long does an induction heating cycle take? Optimize Your Process Speed and Efficiency

- What is the capacity of an induction furnace? Find the Right Size for Your Lab or Foundry