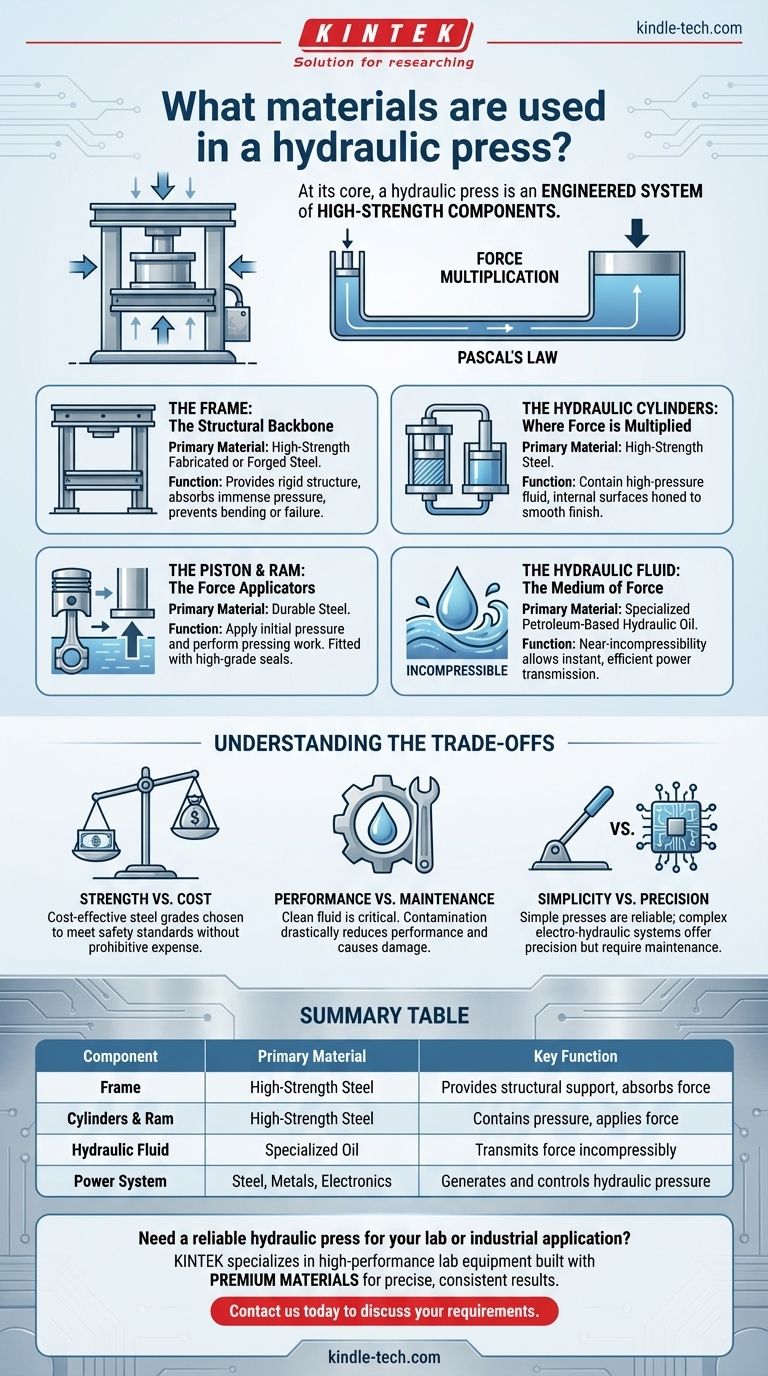

At its core, a hydraulic press is not made of one material but is an engineered system of high-strength components. The primary functional parts are a structural frame, two interconnected hydraulic cylinders (a smaller plunger and a larger ram), and the hydraulic fluid that fills them. These components are almost universally made from high-strength steel to withstand immense operational forces, while the fluid is a specialized, incompressible oil.

A hydraulic press achieves force multiplication not through a single magic material, but by using high-strength steel components to contain and direct pressure through an incompressible fluid, a principle known as Pascal's Law.

The Core Components and Their Materials

A hydraulic press is best understood as a collection of specialized parts, each with a specific material requirement dictated by its function.

The Frame: The Structural Backbone

The mainframe provides the rigid structure that holds all other components in place. It must absorb and counteract the immense pressure generated during operation.

For this reason, the frame is constructed from high-strength fabricated or forged steel. Its design ensures that it does not bend, twist, or fail under loads that can reach thousands of tons.

The Hydraulic Cylinders: Where Force is Multiplied

The system uses two interconnected cylinders of different sizes: a small "plunger" cylinder and a large "ram" cylinder. These act as pressure vessels.

Like the frame, the cylinders are made of high-strength steel capable of containing the high-pressure hydraulic fluid without rupturing. The internal surfaces are honed to a smooth finish to ensure a proper seal for the piston.

The Piston and Ram: The Force Applicators

A piston moves within the smaller plunger cylinder to apply initial pressure to the fluid. This pressure is then transmitted to the ram, a much larger piston in the second cylinder, which performs the actual pressing work.

These components are also made of durable steel and are fitted with high-grade seals to prevent fluid leakage under extreme pressure.

The Hydraulic Fluid: The Medium of Force

The "material" that makes the entire process possible is the hydraulic fluid, which is typically a specialized, petroleum-based hydraulic oil.

This fluid is chosen for its near-incompressibility. When force is applied, it does not lose volume, allowing it to transmit power instantly and efficiently from the small cylinder to the large one.

The Power and Control System

A hydraulic power unit, consisting of a motor and pump, is responsible for moving the hydraulic fluid and generating pressure.

Directional control valves manage the flow of this high-pressure oil, allowing an operator to extend or retract the ram with precision. These systems are a mix of steel, other metals, and electronic components.

Understanding the Trade-offs

The design and material selection for a hydraulic press involve balancing critical engineering and operational factors.

Strength vs. Cost

While exotic steel alloys could provide superior strength, they would make the press prohibitively expensive. Designers select cost-effective steel grades that meet and exceed the required safety and performance standards for the press's intended tonnage.

Performance vs. Maintenance

The hydraulic fluid is the lifeblood of the press, but it is also a potential point of failure. The system must be perfectly sealed.

Contamination of the fluid with dirt, water, or air can drastically reduce performance and damage the pump and cylinders. This creates a trade-off between the high performance of a hydraulic system and its need for a clean, well-maintained fluid environment.

Simplicity vs. Precision

A simple hydraulic press has few moving parts, making it incredibly reliable. However, adding complex electro-hydraulic control systems allows for immense precision in speed and pressure.

This added complexity increases the initial cost and introduces more potential points of failure, requiring more sophisticated maintenance and troubleshooting.

Making the Right Choice for Your Goal

Understanding these materials and components helps you see the hydraulic press as a complete system.

- If your primary focus is how it works: Concentrate on the interaction between the two steel cylinders and the incompressible hydraulic fluid, which is the key to force multiplication.

- If your primary focus is durability: Recognize that the high-strength steel frame and cylinders are the most critical structural materials designed to contain and resist force.

- If your primary focus is maintenance: View the hydraulic fluid as the most important operational material, whose cleanliness and integrity are paramount for the machine's health.

Ultimately, a hydraulic press is a powerful demonstration of how robust materials and fundamental physics combine to create extraordinary force.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Frame | High-Strength Steel | Provides structural support and absorbs force |

| Cylinders & Ram | High-Strength Steel | Contains pressure and applies force |

| Hydraulic Fluid | Specialized Oil | Transmits force incompressibly |

| Power System | Steel, Metals, Electronics | Generates and controls hydraulic pressure |

Need a reliable hydraulic press for your lab or industrial application? KINTEK specializes in high-performance lab equipment, including durable hydraulic presses built with premium materials for precise, consistent results. Let our experts help you find the perfect solution for your material testing, sample preparation, or production needs. Contact us today to discuss your requirements and discover the KINTEK advantage!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production