While a wide variety of metals possess the necessary properties for forging, the process is dominated by materials prized for their strength, malleability, and performance characteristics. The most common materials are carbon and alloy steels, followed by specialized alloys of aluminum, titanium, and copper. The selection is not arbitrary; it is a deliberate choice dictated by the final component's required strength, weight, corrosion resistance, and operating temperature.

The core principle of material selection in forging is not finding a single "best" metal, but rather identifying the alloy whose inherent properties and forgeability most effectively and economically meet the engineering demands of the final application.

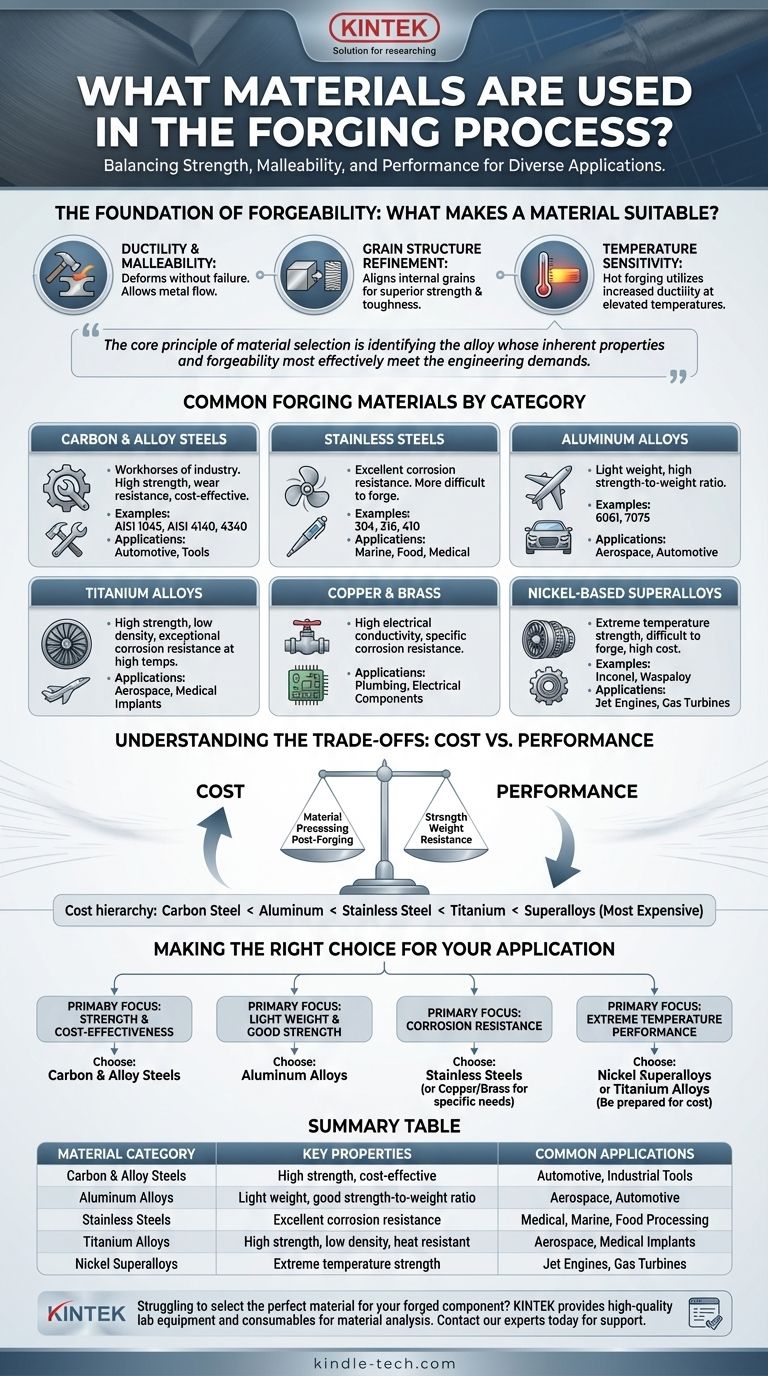

The Foundation of Forgeability: What Makes a Material Suitable?

Before listing materials, it's crucial to understand what makes a metal suitable for the intense deformation of the forging process. The primary factor is the material's ability to be plastically deformed without failing.

Ductility and Malleability

A forgeable material must be ductile (able to be deformed without fracture) and malleable (able to be hammered or pressed into shape). This allows the metal billet to flow and fill the die cavity under immense pressure, creating the desired shape.

Grain Structure Refinement

One of the main benefits of forging is that it refines and directs the metal's internal grain structure. This process aligns the grains with the shape of the part, eliminating porosity and producing a component that is significantly stronger and tougher than a cast or machined equivalent.

Temperature Sensitivity

Most forging is performed on heated metal (hot forging) because metals become more ductile and less resistant to deformation at elevated temperatures. The material's response to heat and its optimal forging temperature range are critical selection criteria.

Common Forging Materials by Category

The choice of material is a direct function of the part's intended use. Each category offers a distinct profile of cost, performance, and manufacturing complexity.

Carbon and Alloy Steels

These are the workhorses of the forging industry due to their excellent strength, wear resistance, and cost-effectiveness. They are used in everything from automotive crankshafts to industrial tools.

- Common Examples: AISI 1045 (Carbon Steel), AISI 4140, 4340 (Alloy Steels).

Stainless Steels

Chosen when corrosion resistance is the primary requirement. While generally more difficult to forge than carbon steels, they are essential for applications in the food processing, medical, and marine industries.

- Common Examples: 304, 316 (Austenitic), 410 (Martensitic).

Aluminum Alloys

When light weight is critical, aluminum is the material of choice. The aerospace and high-performance automotive industries rely heavily on forged aluminum for its high strength-to-weight ratio.

- Common Examples: 6061, 7075.

Titanium Alloys

Titanium offers a unique combination of high strength, low density, and exceptional corrosion resistance, even at elevated temperatures. This makes it ideal for critical aerospace components, jet engine parts, and medical implants.

Copper and Brass

These alloys are forged for applications requiring high electrical conductivity or specific corrosion resistance properties not met by stainless steel. They are commonly found in plumbing fittings, valves, and electrical components.

Nickel-Based Superalloys

These materials are reserved for the most demanding environments, such as the hot sections of jet engines and gas turbines. They retain incredible strength at extreme temperatures but are very expensive and difficult to forge.

- Common Examples: Inconel, Waspaloy.

Understanding the Trade-offs: Cost vs. Performance

Choosing a material is a balancing act between the desired performance and the total cost of the finished part. The raw material is only one part of the equation.

The Cost of Material

There is a clear cost hierarchy. Carbon steels are the least expensive, followed by aluminum, stainless steel, titanium, and finally, the extremely expensive nickel-based superalloys.

The Cost of Processing (Forgeability)

A material's forgeability has a direct impact on production cost. Materials like titanium and superalloys are far more resistant to deformation than steel, requiring more energy, more powerful equipment, and causing significantly higher wear on the forging dies.

Post-Forging Requirements

The total cost must also include any necessary secondary operations. Many high-strength alloys require complex and expensive heat treatments after forging to achieve their final properties, adding to the overall expense.

Making the Right Choice for Your Application

Your material selection should be guided by the single most important requirement for your component.

- If your primary focus is strength and cost-effectiveness: Carbon and alloy steels are almost always the correct starting point for a wide range of industrial and mechanical applications.

- If your primary focus is light weight with good strength: Aluminum alloys offer the best balance for aerospace, automotive, and other applications where weight reduction is critical.

- If your primary focus is corrosion resistance: Stainless steels are ideal for marine, food, and medical environments, while copper alloys serve specialized needs in plumbing and electrical systems.

- If your primary focus is performance at extreme temperatures: Nickel-based superalloys or titanium alloys are necessary, but you must be prepared for their significant cost and manufacturing challenges.

Ultimately, selecting the right forging material is a calculated decision that balances the engineering demands of the part with the economic realities of production.

Summary Table:

| Material Category | Key Properties | Common Applications |

|---|---|---|

| Carbon & Alloy Steels | High strength, cost-effective | Automotive parts, industrial tools |

| Aluminum Alloys | Light weight, good strength-to-weight ratio | Aerospace, automotive components |

| Stainless Steels | Excellent corrosion resistance | Medical, marine, food processing |

| Titanium Alloys | High strength, low density, heat resistant | Aerospace, medical implants |

| Nickel Superalloys | Extreme temperature strength | Jet engines, gas turbines |

Struggling to select the perfect material for your forged component? The right choice is critical for performance, durability, and cost-efficiency. KINTEK specializes in providing the high-quality lab equipment and consumables needed to analyze and test these materials, ensuring your forging process is a success. Our experts can help you navigate the complexities of material science. Contact us today to discuss your project requirements and discover how we can support your laboratory needs. Get in touch via our Contact Form

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- Why does SEM need gold coating? Prevent Charging & Get Crisp Images

- What are the feedstocks for biochar production? Choose the Right Material for Your Application

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- Can brazing be used to join two different base metals? Unlock Strong, Reliable Dissimilar Metal Joints

- Why is a laboratory magnetic stirrer required for benzoic acid esters? Boost Reaction Speed & Yield with High RPM

- What role does a precision laboratory drying oven play in the synthesis of GO-PANI nanocomposites? Protect Material Integrity

- What temperature does sintering occur? Master the Thermal Profile for Your Material

- Can pyrolysis oil be refined? Unlocking High-Value Fuels from Bio-Crude