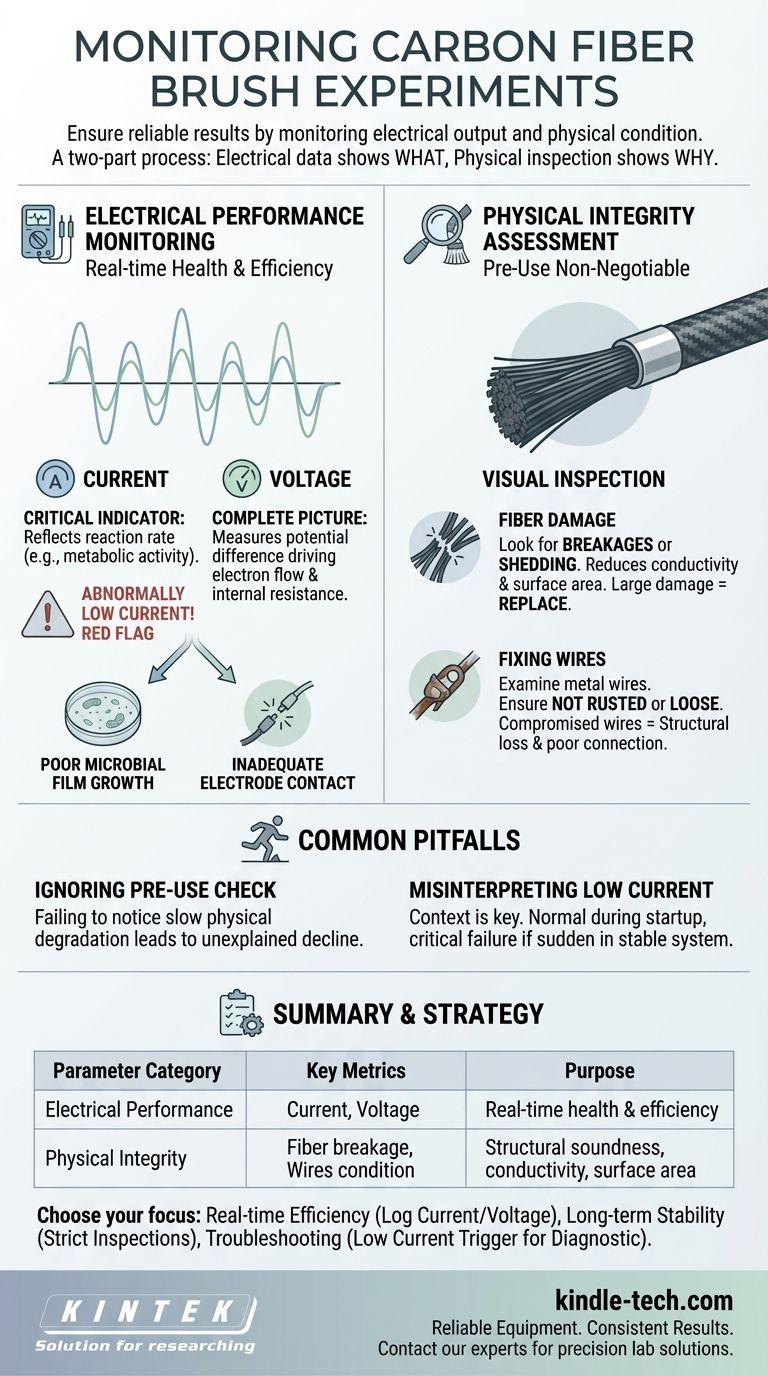

When conducting an experiment with a carbon fiber brush, you must monitor two primary categories of parameters: the electrical output during the experiment and the physical condition of the brush before use. The key electrical metrics are current and voltage, which serve as direct indicators of the ongoing process's health and efficiency.

The core principle is that monitoring a carbon fiber brush is a two-part process. Electrical data tells you what is happening in real-time, while a physical inspection tells you why performance may be compromised before the experiment even begins.

Electrical Performance Monitoring

Consistent electrical monitoring is the most direct way to assess the performance and stability of your electrochemical or biological system.

Monitoring Current

The current output is often the most critical performance indicator. It reflects the rate of the reaction you are studying, such as the metabolic activity in a microbial fuel cell.

An abnormally low current is a significant red flag. It demands immediate investigation as it typically points to one of two root causes.

Diagnosing Low Current

A drop in current suggests a breakdown in the system. The most common culprits are poor microbial film growth on the brush or inadequate electrode contact, preventing an efficient electrical connection.

Monitoring Voltage

While current measures the flow of electrons, voltage measures the potential difference driving that flow. Monitoring both provides a complete picture of the system's power output and internal resistance.

Physical Integrity Assessment

A pre-use inspection is a non-negotiable step to ensure your equipment is sound. A physically compromised brush will inevitably lead to poor or misleading results.

Visual Inspection for Fiber Damage

Before each use, carefully inspect the brush. Look for any significant breakages or shedding of the fine carbon fibers.

A large number of broken fibers is cause for replacement. This damage directly reduces both the brush's conductivity and the available surface area for microbial attachment or chemical reaction.

Checking the Fixing Wires

Examine the metal wires that hold the carbon fiber bundle together. Ensure they are not rusted or loose.

Compromised fixing wires can lead to a loss of structural integrity and a poor electrical connection, invalidating your experimental data.

Common Pitfalls to Avoid

Simply collecting data is not enough. Understanding the context and potential failure points is crucial for accurate interpretation.

Ignoring the Pre-Use Check

A common mistake is to focus solely on the electrical data while being unaware of the brush's slow physical degradation. This can lead to a gradual, unexplained decline in performance that could have been prevented by a simple visual check.

Misinterpreting a Low Current

While a low current is a warning sign, it's essential to understand the context of your specific experiment. A low current during an initial startup phase may be normal, whereas a sudden drop in a stable system signals a critical failure.

Making the Right Choice for Your Goal

Your monitoring strategy should align with your primary experimental objective.

- If your primary focus is real-time process efficiency: Continuously log current and voltage to track performance and immediately identify any operational deviations.

- If your primary focus is long-term stability: Implement a strict pre-use and post-use inspection protocol to track the physical degradation of the brush over time.

- If you are troubleshooting poor performance: Use a low current reading as a trigger to conduct a full diagnostic, starting with a physical inspection of the brush and its connections.

Proactive and comprehensive monitoring is the foundation of reliable and repeatable experimental results.

Summary Table:

| Parameter Category | Key Metrics to Monitor | Purpose / What It Indicates |

|---|---|---|

| Electrical Performance | Current, Voltage | Real-time health and efficiency of the electrochemical/biological process. |

| Physical Integrity | Fiber breakage/shedding, Condition of fixing wires | Ensures structural soundness, conductivity, and surface area for reactions. |

Ensure your lab's experiments are built on a foundation of reliable equipment. Proper monitoring is key to valid data, and it starts with high-quality supplies. KINTEK specializes in precision lab equipment and consumables, including durable carbon fiber brushes and monitoring tools designed for electrochemical applications.

Let us help you achieve consistent, accurate results. Contact our experts today to find the right solutions for your laboratory's specific needs.

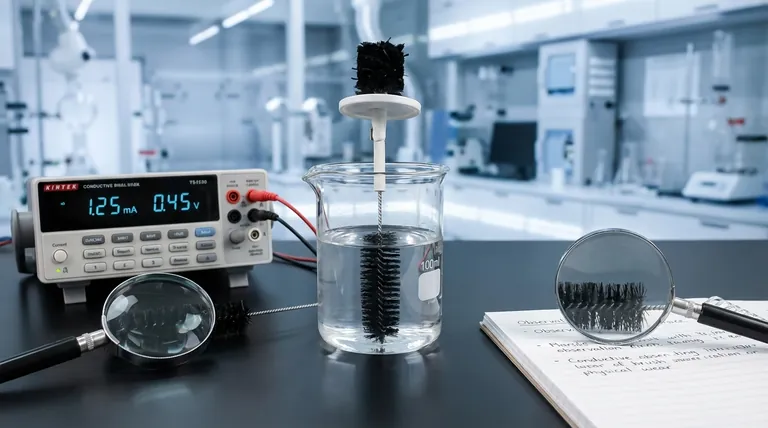

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Large Vertical Graphite Vacuum Graphitization Furnace

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How should a carbon fiber brush be stored after cleaning? Preserve Performance and Longevity

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice

- What is the recommended cleaning procedure for a carbon fiber brush after use? Extend Brush Life and Maintain Performance

- What checks should be performed on a carbon fiber brush before use? Ensure Reliability in Your Lab Processes

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity