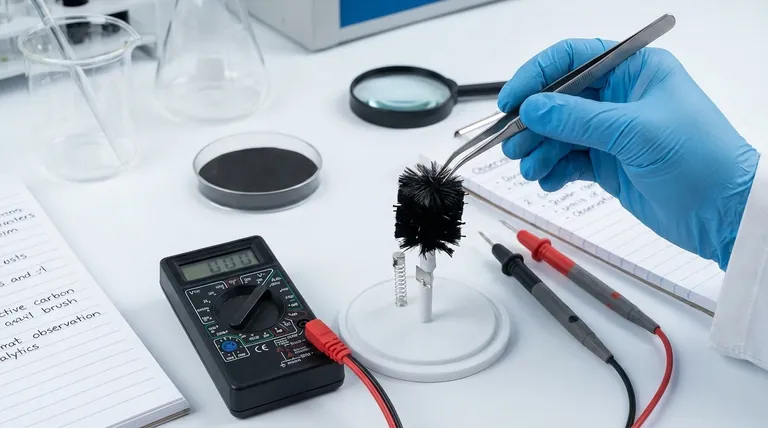

A regular maintenance inspection for a carbon fiber brush is a two-part process. It involves a physical check for broken or shedding fibers and an assessment of the fixing wires for looseness or corrosion. This visual inspection ensures the brush's structural and electrical integrity remains intact for optimal performance.

The core of effective maintenance is not just spotting damage, but understanding that a brush's physical condition is directly tied to its electrical performance. Proactive inspection prevents gradual performance decay and ensures the reliability of your data or process.

The Two Pillars of Brush Integrity

Effective maintenance rests on assessing both the brush's physical structure and its operational output. One is a leading indicator for the other.

Pillar 1: Physical Condition Assessment

A visual inspection is your first line of defense against performance degradation. This should be performed before initial use and at regular intervals.

Inspecting Fiber Integrity The dense bundle of carbon fibers is the functional heart of the brush. Look for any signs of breakage, shedding, or significant fraying.

Even minor fiber loss can reduce the total surface area, which is critical for applications like microbial attachment in fuel cells. It can also impact the brush's overall conductivity.

Assessing the Fixing Wires The fibers are typically held together by a central wire, often made of titanium for its corrosion resistance. Check to ensure this wire is not rusted, corroded, or loose.

A compromised fixing wire can lead to a catastrophic failure of the brush structure or create a point of high electrical resistance, disrupting the entire circuit.

Pillar 2: Operational Performance Monitoring

For brushes in continuous operation, physical checks should be supplemented with performance data analysis.

Monitoring Electrical Output Keep a close watch on key parameters like current and voltage. A sudden or gradual drop in output is a critical symptom.

An abnormally low current can signal issues beyond the brush itself, such as poor microbial film growth. However, it often points to a degraded brush or inadequate electrode contact, warranting an immediate physical inspection.

A Practical Inspection Schedule

Consistency is key. A simple schedule removes guesswork and ensures problems are caught early.

The Pre-Use Check

Before installing any new brush, perform a thorough initial inspection. This establishes a baseline and confirms you are not starting with a defective component.

Routine In-Operation Checks

For systems in continuous use, like in biofuel cell research, a periodic inspection is non-negotiable. A monthly check is a reliable starting point. Log your findings to track the rate of degradation over time.

Understanding the Trade-offs: Repair vs. Replace

Not all damage is equal. Knowing when to perform a minor repair versus a full replacement is crucial for both performance and budget.

When to Trim: Minor Damage

If you discover a small number of broken or frayed fibers, they can be carefully trimmed away. This prevents them from tangling with or affecting the surrounding fibers. This is a stop-gap measure for minor, localized damage.

When to Replace: Significant Degradation

If you find a large number of broken fibers or any corrosion on the fixing wire, the brush must be replaced. At this point, the loss of conductivity and surface area will negatively impact your results. Attempting to use a severely degraded brush compromises the integrity of your entire experiment or process.

Making the Right Maintenance Decision

Your maintenance strategy should align directly with the goals of your project.

- If your primary focus is data integrity and peak performance: Be conservative and replace the brush at the first sign of significant fiber shedding or any wire corrosion.

- If your primary focus is maximizing lifespan on a limited budget: Meticulously trim minor damage and monitor electrical output closely to extract the maximum usable life, but be prepared to replace it as soon as performance drops below an acceptable threshold.

Ultimately, consistent and methodical maintenance is what guarantees your carbon fiber brush remains a reliable component, not a variable.

Summary Table:

| Inspection Aspect | Key Checks | Frequency |

|---|---|---|

| Physical Condition | Fiber breakage/shedding; Wire corrosion/looseness | Before use & Monthly |

| Operational Performance | Current/Voltage output; Electrode contact | Continuous Monitoring |

| Action Decision | Trim minor damage; Replace for significant degradation | As Needed |

Ensure your lab's precision with reliable equipment from KINTEK!

Just as a well-maintained carbon fiber brush is crucial for consistent experimental results, using high-quality, durable lab equipment is fundamental to your research integrity and efficiency. KINTEK specializes in providing top-tier lab equipment and consumables tailored to your laboratory's specific needs.

Let us help you maintain peak performance in all your processes. Contact our experts today to find the perfect solutions for your lab!

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Graphite Vacuum Continuous Graphitization Furnace

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Laboratory Jaw Crusher

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

People Also Ask

- How should a carbon fiber brush be stored after cleaning? Preserve Performance and Longevity

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice

- What are the 3 types of biomass? A Guide to Woody, Agricultural, and Waste Sources

- What are 3 benefits of biomass energy? Turn Waste into Renewable Power

- What are 3 types of biomass? A Guide to Wood, Waste, and Biofuels for Energy