Yes, a carbon brush is a good conductor of electricity, but its role in a motor or generator is far more sophisticated than simply conducting a current. Its selection is a deliberate engineering choice where perfect conductivity is sacrificed in favor of other critical properties that ensure the machine's longevity and reliable operation.

The core takeaway is that carbon brushes are not chosen because they are the best conductors, but because they offer a unique and essential balance of electrical conductivity, self-lubrication, and controlled wear that no simple metal can provide.

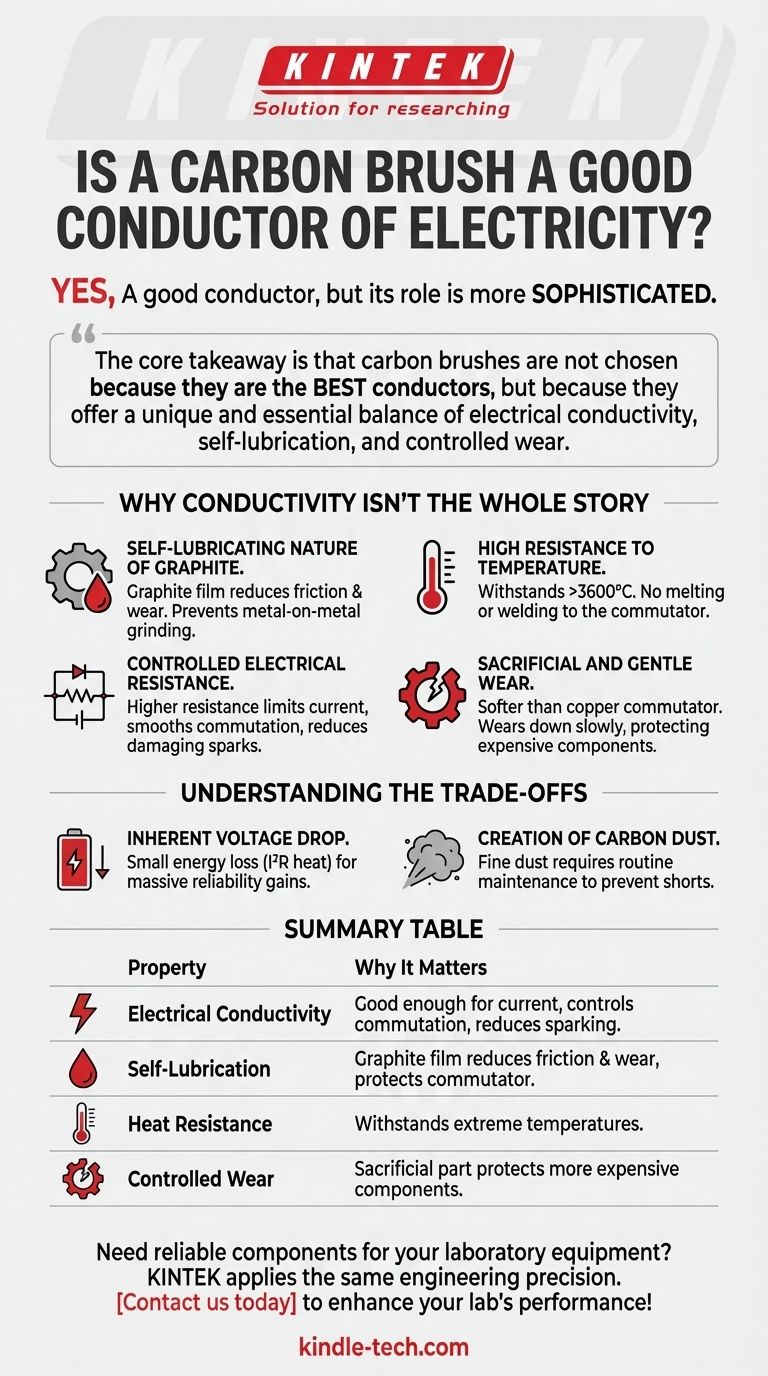

Why Conductivity Isn't the Whole Story

While conducting electricity is the brush's primary function, several other properties of carbon are what make it the ideal material for the job. Using a more conductive material, like copper, would lead to rapid self-destruction of the motor's most critical components.

The Self-Lubricating Nature of Graphite

Carbon, in the form of graphite, is naturally self-lubricating. As the brush makes contact with the spinning commutator or slip ring, a thin film of graphite is deposited.

This film drastically reduces mechanical friction and wear. A metal brush, by contrast, would grind against the commutator, causing severe abrasion, high friction, and eventual failure.

High Resistance to Temperature

Electric motors generate significant heat, especially at the point of contact between the brush and the commutator. Current flowing through this contact point creates electrical and frictional heat.

Carbon has a very high melting and sublimation point (over 3600°C), allowing it to withstand these extreme operating temperatures without melting or welding itself to the commutator, a common failure mode for metal contacts.

Controlled Electrical Resistance

Perhaps counter-intuitively, carbon's moderate—not excellent—conductivity is a key advantage. Its internal resistance is higher than that of copper.

This higher resistance helps to limit and control the electrical current as the brush momentarily shorts adjacent commutator segments. This process, known as commutation, would otherwise cause large, damaging sparks. The brush's resistance smooths this transition, improving commutation and extending the life of the motor.

Sacrificial and Gentle Wear

A fundamental design principle in rotating machinery is that the cheapest, most easily replaced part should be the one that wears out.

Carbon is softer than the copper commutator it runs against. This ensures that the inexpensive carbon brush slowly wears down over time, sacrificing itself to protect the much more expensive and difficult-to-replace commutator.

Understanding the Trade-offs

The choice of carbon is a masterclass in engineering compromise. No material is perfect, and the primary drawback of a carbon brush is directly related to its advantage.

Inherent Voltage Drop and Power Loss

The same internal resistance that improves commutation also causes a voltage drop across the brushes. This means a small amount of energy is inevitably lost as heat (known as I²R loss).

In high-performance or low-voltage applications, this voltage drop can impact the motor's overall efficiency. However, this small efficiency loss is almost always an acceptable trade-off for the massive gains in reliability and component lifespan.

Creation of Carbon Dust

As the brushes wear down, they create a fine carbon dust. While generally benign, this conductive dust can accumulate in the motor housing and, in rare cases, cause short circuits if not cleaned out during routine maintenance.

Making the Right Choice for the Application

The specific blend of carbon and other materials (like copper) in a brush is tailored to the motor's specific job. Understanding the goal clarifies why pure carbon is the foundation.

- If your primary focus is maximum electrical efficiency above all else: A pure metal contact might seem superior, but it would result in catastrophic friction, sparking, and commutator wear in a rotating machine.

- If your primary focus is reliability, longevity, and smooth operation: A carbon-based brush is the definitive choice, perfectly balancing conductivity with the protective properties of lubrication and controlled wear.

Ultimately, the carbon brush serves as a protective, functional interface, ensuring the entire system operates reliably for thousands of hours.

Summary Table:

| Property | Why It Matters for Carbon Brushes |

|---|---|

| Electrical Conductivity | Good enough to conduct current, but high resistance helps control commutation and reduce sparking. |

| Self-Lubrication | Graphite film reduces friction and wear, protecting the commutator. |

| Heat Resistance | Withstands extreme operating temperatures without melting. |

| Controlled Wear | Softer than the commutator, acting as a sacrificial, replaceable part. |

Need reliable components for your laboratory equipment? The carbon brush is a perfect example of how the right material choice ensures longevity and smooth operation. At KINTEK, we apply the same engineering precision to our range of lab equipment and consumables. Let our experts help you select the perfect solutions for your laboratory's unique needs. Contact us today to enhance your lab's performance and reliability!

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Laboratory Jaw Crusher

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is the problem in heat treatment process? The High Cost of Preventing Surface Defects

- What is the primary function of a laboratory centrifuge? Master PAAMP-b-PVK Block Copolymer Purification

- What temperature does molten steel melt? Understand the Melting Range, Not a Single Point

- Is diamond a better conductor of heat than graphite? Unlocking the Atomic Secrets of Thermal Conductivity

- Why is high-purity nitrogen used for deoxygenation? Ensure Accuracy in HTHP Corrosion Experiments

- Can iron evaporate? Discover the Extreme Science Behind Gaseous Metals

- What is the difference between thermal evaporation and molecular beam epitaxy? Choose the Right Thin-Film Deposition Method

- What is the main characteristic of oil-free diaphragm vacuum pumps? Guaranteeing a Contamination-Free Vacuum